Claan Ball Machine High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

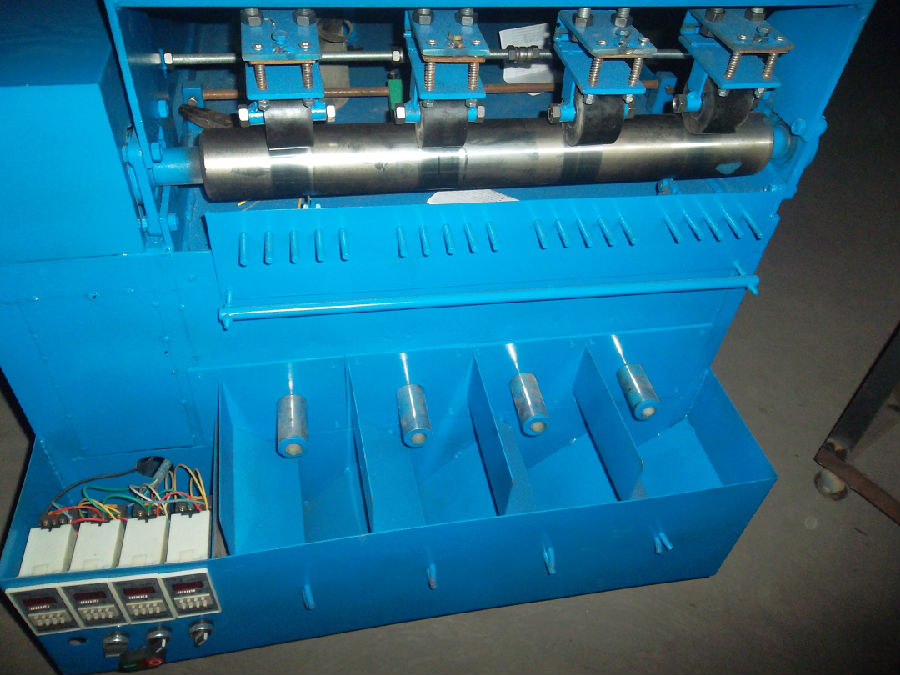

there is 3 balls and 4 balls Cleaning ball machine

This kind of machine could for both flat and round cleaning ball production

manufaturer spiral scouring ball machine,it is full-automatic 12hats,22blades

Power: 380V/220V ,2.2KW

Scourer ball separating :full automatic, low voltage melted down

Production Capacity: 10kgs/hours

Machine weight:380kgs

Machine size:210cm X85CM X 130CM (lengthXwidth Xheight )

· Output :more than 100kgs/8hours for scourer balls

Commodity | Description |

Scouring ball machine (16 hats and 22 blades) | Power :2.2KW voltage :380V Out size: 2.1M*0.85M*1.3M weight: 380kgs Production : 10kgs /h |

Size | Power (kw) | Setting wire | Scourer Ball separating | Work accelerating | Machine weight(kg) | YieldHour) | ||

1 | 2.0 | 4 wires double ball output | Full-automatic

| 1600r/min reached within3-5s | 495 | 8kg | ||

2 | 2.2 | 6 wires treble ball output | 520 | 10kg | ||||

Export packing size | L*W*H:1400mm*1150mm*1400mm | |||||||

Main Features:

Output: 32~48KGS/8Hrs for mesh scourer

Power SupplyAC 380V AC 220V (Custom-made)

Stepless Speed Regulation, Japanese OMRON time controller, PHILIPS sensor automatic counting, size and weight of final scourer could be preset as per requirement.

Output capacity of Double-Needle manufacturing is twice as much as an ordinary mesh scourer making machine.

Not only compression rollers and weaving parts have each separated speed ratio of transmission system, but wire-broken stop motion also works well.

Automatic cutting with high performance air compressor system, its shearing tools are hidden blades with multi-sides sawtooth utilizing the latest company technology we owned (Patent number: CN2009211975.7). It made shearing more accurate, sharper and safer.

Easy operation, one worker controls multiple machines. Wire loading, flatting, mesh waving, and scourer shearing, all finished in one time.

Product DetailsMain Features:

Output: 64kg/8hrs

Full-automatic operation, available for spiral scourer!

Producing general scourer just by exchanging the multi-lines system

Material wire setting: 4wires doubles scourers

Full-automatic scourer ball dividing system

Final scourer separating melted down by low voltage controlled

Materials feeding: 0.13mm-0.2mm stainless steel wire

Motor power (kw):2.2kw

Power supply AC 380V

Send your message to us

Claan Ball Machine High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches