China Al2O3 70% Nature Calcined Bauxite Low Price with Detailed Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

China Al2O3 70% Nature Calcined Bauxite Low Price with Detailed Specifications

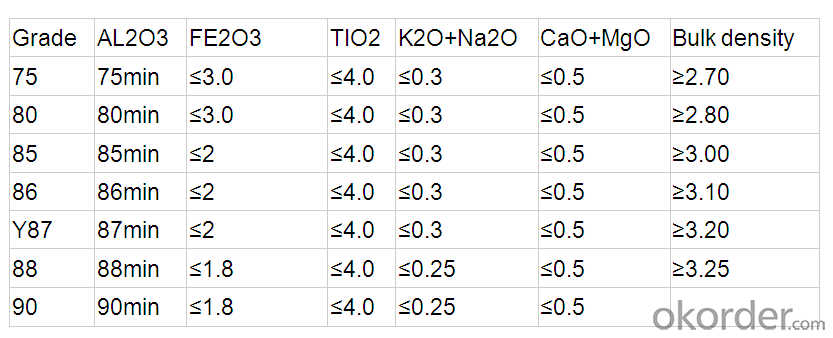

Specifications

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Calcined bauxite

1. Bauxite (aluminous soil; Bauxite) is also called the alumina or bauxite, main ingredients are alumina,

2. hydrated alumina containing impurities, is an earthy mineral. White or gray, brown and yellow or light red by iron.

3. From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3 is not transparent, very brittle. Very difficult to melt.

4. Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution. Mainly used for aluminium, refractory material.

Product Description:

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

(4) aluminum silicate refractory fiber. With light weight, high temperature resistance, good thermal stability,

low thermal conductivity, heat capacity is small and the advantages of resistance to mechanical shock.

Used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy,

defense and other industries.

(5) in magnesia and bauxite clinker as raw materials, add the appropriate binder,

used for pouring ladle whole ladle lining has particularly good effects.

(6) manufacture alumina cement, abrasive materials,

ceramic industry and chemical industry can be aluminum of various compounds

Product Pictures:

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What are unshaped fire-resisitance materials?

- Refractory castable, refractory plastic material, usually classified according to construction and manufacture method, unfired bricks precast block, refractory pressed into material, refractory cast material, refractory coating, refractory ramming material there are many classification methods

- Q: What's the feature of construction external wall fireproof and thermal inuslation matertial?

- Building external wall fireproof thermal insulation material is made by stirring, casting, foam protecting and cutting with industrial by-product gypsum as the main raw material, adding sulphate aluminium cement, fly-ash, polymer additives and other materials. It has excellent properties of respiratory function , air permeability, water impermeability, recycling system data, wind load resistance, shock resistance, thermal insulation, fireproof and sound insulation.

- Q: What is unshaped refractory?

- Unshaped refractory is a mixture made of aggregate and powder, binder or other admixture. It can be used directly or after proper liquid mixing. The material is a new type of refractory material after calcination, the refractoriness of not less than 1580 DEG C unshaped refractory materials by various varieties, production method and use method thereof can be divided into concrete, pouring material, plastic, ramming material, gunning, casting material, coating material, dry ramming material fire, mud, all kinds of repairing materials (with asphalt surface patch charge, Ma Dingsha) also do not belong to the shape of the column.

- Q: What's the refractory material?

- Frequently used refractory material: AZS brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nonoxide refractories like nitride, silicide, sulfide, boride and carbide, and oxide refractories like calcium oxide, chromium hemitrioxide, alumina, magnesium oxide and beryllia. In general, the refractory material include the above. For more information, you can ask for specific advice.

- Q: The effect of a high content of water in liquid resin exerted on refractory material?

- For one thing, Substandard whiteness, transportation, low quality and the storage of refractory material may account for this. For another, a high content of moisture reduced the performance of refractory material. A high content of moisture is equal to buy water with same money in terms of trade settlement. Based on this, we can’t consider the super-standard water content from a single aspect, because the water content in refractory material is definitely super-standard, and another problem is particle size. Many people hold the idea that excessive amount of water content may revive its original performance, but it tends to have influenced the quality of refractory material.

- Q: What refractories are resistant to fluorine gas?

- It is recommended to use fused-quartz brick, which will produce hydrofluoric acid fluorine (an acidic gas) when water vapors. It is cheap. While it is recommended to use silica?brick if it exceeds 1,200 degrees. So acidic refractory is an advisable refractory for using. It works well if the temperature is below 1200 degrees.

- Q: what's the fire endurance of fireproof?panel?

- Fire endurance of fireproof?panel is 3 hours, for example, 12 mm non-asbestos fiber reinforced calcium silicate board, fireproof?panel, two single 75 keel. through the monitoring of national fireproof construction materials quality supervision center, it's security and refractory time will reach over 3 hours. Fireproof board, also called fire endurance board, scientific name is thermosetting resin impregnated paper laminated wood.

- Q: how is the high-temperature flame-retardant fibre board?

- ------ Different category of high temperature materials including refractory and heat-resistant material, inorganic compounds, high-molecular polymer. refractory usually refers to an inorganic material that can endure temperature above 1580 ℃ . They are for building kiln, combustion chamber and other buildings that require heat resistance materials. It is generally made of quartz sand, clay, magnesia mineral, dolomite.

- Q: Development trend of refractory industry

- In the central provinces in Henan, Shanxi, Liaoning China main manufacturer of refractory material, which is the main origin of three China bauxite, magnesite and other refractory materials; refractories industry by the end of May 2009 more than 3236 enterprises; industry revenue reached 67 billion 52 million 540 thousand yuan, Henan Province, Liaoning, Shandong, Jiangsu, Hebei and other regions, and refractories industry in the development of better leading enterprises, such as blue and white, accessible, prco etc. at present, its sales in the industry in the proportion is still small, the largest sales is also inadequate in refractory industry in 4%. An enterprise should play a leading role in leading enterprises in the industry, and its turnover in the industry should be more than 15%. Obviously, at present the refractory industry in the leading enterprises do not have, and the refractory industry concentration needs to be improved, and the existing resources in the refractory industry integration, is undoubtedly the way this process effective and efficient.

- Q: How to divide fire resistant level of fire door?

- The classification of fire resistant level of fire door: Grade A is not less than 1.2h. Grade B is not less than 0.9h. Grade C is not less than 0.6h. It is suitable for fire door with different levels: Grade A: Equipment room (such as fire-pump room,power distribution room, generator room, smoke control fan room, etc) door, fire?compartment, door on firewall; Grade B: Eclosed staircase, front door of stair room, smoke-proof?staircase and fire elevator share lobby door, front door of fire elevator, household door which directly opens to front room or shares room; Grade C: The vertical shaft door, such as strong electric wells, weak electric wells, pipe shaft door and air conditioning facilities. I hope this information can help you.

Send your message to us

China Al2O3 70% Nature Calcined Bauxite Low Price with Detailed Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords