Chain Link Fence(PVC&Galvanized) Hot Dipped Galvanized Chain Link Fence

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 3000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Chain link Wire Mesh Description:

Chainlink Wire Mesh is finished of Electro Chain Link Fencing With 7-15G per Square Meter Zinc Coating; Hot Dipped Galvanized Chain Link Fencing with 35-400G per Square Meter Zinc Coating; PVC Coated Chain Link Fencing (Green, Black, etc.)

Chainlink Wire Mesh woven from steel wire, is probably the most widely used and versatile of all fencing fabrics, available in a variety of wire gauges and mesh sizes to suit specific applications.Available in three finishes, heavily galvanised, P.V.C coated with a bright core or for double protection, PVC coated with a galvanized wire core.Chain link fence is recommended for use for House Garden fronts and divisions, Children's Playgrounds, Playing Fields, Recreational Grounds, mainly galvanized iron wire, stainless steel wire, PVC wire, and aluminium alloy wire.

Chainlink Wire Meshare one of the most well known perimeter fencings since they are easy to build, cost effective and long lasting, fulfilling the motive of keeping people in/out of a particular region, PVC coated, electro or hot dipped galvanized. after syrface treatment chain link fence has a heavy galvanized coating to ensure a long life.

2.Main Features of Chain link Wire Mesh:

Low carbon steel diamond mesh has a heavy galvanized coating to ensure a long life.

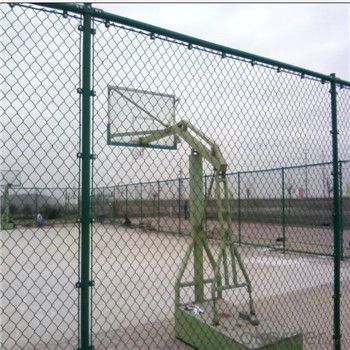

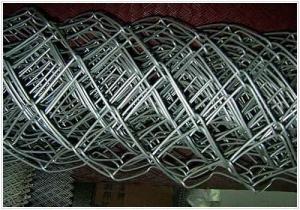

3. Chain link Wire Mesh Images

4. Chain link Wire Mesh Specification

Netting fencings (galvanised wire) | ||||||||

wire diameter mm | mesh size mm | roll length m | standard netting heights mm | standard post heights mm | ||||

1 | 5×5 | 10 | 500 | 1000 | ||||

1000 | 1500 | |||||||

1.2 | 10×10 | 10 | 1250 | 2000 | ||||

20×20 | 1500 | 2000 | ||||||

1.4 | 20×20 | 10 | 2000 | 2500 | ||||

1.8 | 30×30 | 10 | 2500 | 3000 | ||||

2.5 | 40×40 | 10 | 3000 | 3500 | ||||

2.8 | 50×50 | 10 | 4000 | 4500 | ||||

3 | 50×50 | 10 | 5000 | 5500 | ||||

4 | 60×60 | 10 | ||||||

Netting fencings (PVC coated wire) | ||||||||

wire diamater mm | mesh size mm | roll length m | standard netting heights mm | standard post heights mm | Standard netting colours | |||

1.8 | 20×20 | 10 | 500 | 1000 | green RAL 6005 | |||

1000 | 1500 | brown RAL 8019 | ||||||

1250 | 2000 | |||||||

1500 | 2000 | |||||||

1.8 | 30×30 | 10 | 2000 | 2500 | ||||

2.5 | 40×40 | 10 | 2500 | 3000 | ||||

2.8 | 50×50 | 10 | 3000 | 3500 | ||||

3 | 60×60 | 10 | 4000 | 4500 | ||||

4.5 | 65×65 | 10 | 5000 | 5500 | ||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1:Are you manufacturer?

Yes,we are. Chain link fence is used as fencing for sports field, river banks, construction and residence, also animal fencing. Woven diamond pattern provides strong, durable and flexible construction. The closely spaced diamond mesh construction gives your fence linear strength and springy texture to protect horses from injury and prevent predators from entering paddocks and pastures.

Q2:What is the advantage of the Chainlink Wire Mesh?

1)The chain link is automatically wound to form rolls when the desired length is manufactured.

2)The machine is controlled by PLC automatic controller, so only one person is needed to operate it.

3)One side or both sides of the end of net hole is twisted or with burr in edge.

4)Use compacting machine to make it into rolls.

Q3:Do you inspect the finished products?

Yes,each step of production and finished products will be carried out inspection by QC department before shipping.

- Q: How the wire is welded

- Resistance welding, solder joint relative to welding beautiful. iron wire. The use of resistance welding, can be in a very short time, high current welding.

- Q: Wall tiles how to hang iron wire mesh

- Cold galvanizing process: cold galvanized is degreased, rusted, showing a dirty, penetrating welded wire mesh, hanging in the cathode of the special plating tank, galvanized anode. Connected to the DC power supply, the anode of the zinc ions migrate to the cathode and discharge on the cathode, so that the welding wire coated with a layer of zinc layer method;

- Q: How does proe draw wire mesh?

- The main is the rest assured that the grid generation, first in accordance with the form of a grid to draw a curve, of course,

- Q: In the chemical experiment, how does the wire mesh use? What are the effects?

- So that the catalytic reaction of iron as a catalyst is more pronounced for the blocking effect. In the solid-liquid reaction in a kind of controllable gas

- Q: What is the barbed wire in the cable line?

- If there is no such network, the TV signal is highly susceptible to some of the frequency of interference, resulting in increased noise on the screen, and even lead to poor synchronization.

- Q: What is the barbed wire fence? What is the general specification?

- It is drawn from the wire rod into a thin wire (cold wire), and then through a large welding machine will wire welding (that is, we commonly known as wire mesh).

- Q: How is the wire mesh made

- saponification, drying, drawing, annealing, cooling, pickling, washing, galvanizing, packaging and the like to produce wire Iron ingot (ingot).

- Q: What is the use of wire

- Iron is a long time will rust. Iron easily rust, in addition to its chemical nature of lively, but also with the outside world conditions also have a great relationship.Water is easy to rust the iron one of the material, iron into the water

- Q: Why do you want to shop a barbed wire?

- Brush the second time mortar, pay attention to the cement composition of the mortar than the first pass is low, and plastering the wall should do the treatment of water, the wall of the draft should be no less than 3cm depth, wiping the second pass Of the time, the first gray should have the necessary strength, so that after the wire hanging up there will not be cracks!

- Q: What is the role of wire in the wire

- The innermost copper wire, is the current carrying effect, used for conductive transmission.

Send your message to us

Chain Link Fence(PVC&Galvanized) Hot Dipped Galvanized Chain Link Fence

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 3000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords