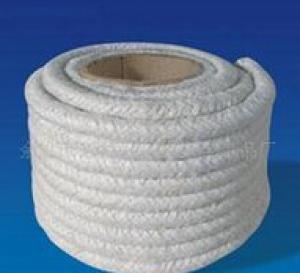

Ceramic Fiber Textiles Twisted Rope

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 40 Rolls kg

- Supply Capability:

- 10 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Twisted Rope

Ceramic fiber twisted ropes normally contain 16 to 20% rayon fiber which will burn out at high temperature, but has no effect on the properties of the products. Ceramic fiber twisted ropes are manufactored from high quality ceramic fiber yarn.

High performance ceramic fiber material fabricated from E-glass or stainless steel wire 304 or 310 reinforced inserted ceramic fiber yarn which is braided around a core of ceramic fiber cord to form a packing in round section. It is fabricated from ceramic fiber yarn twisted left hand/right hand together to form a rope of specified diameters ranging from 3mm to 50mm, with glass filament, stainless steel wire or high temperature alloy wire inserted to provide high strength at elevated temperature.

Feature of Ceramic Fiber Twisted Rope

Low heat storage

Excellent chemical stability

Low thermal conductivity

Acid, oil, vapor resistance

Non-toxicity, environmental protection

Excellent thermal shock resistance

Excellent sound absorptio

Good compression strength

Application of Ceramic FIber Twisted Rope

Expansion joint packing

Protection for cable and fuel tunnel

Fascinated yarn, and covering for fire proof

Seals for stoves and ovens

Bulb in tadpole gaskets, wick for oil burning apparatus, fireproof wrap and insulation

Door for industrial kiln

Curtain for industrial furnace

Radiant tube packing for heat- treated furnaces

Packing of Ceramic Fiber Twisted Rope

Technical Data of Ceramic Fiber Twisted Rope

|

|

CERAMIC FIBER TEXTILES | |

|

|

Classification Temperature (℃) | 1260 |

|

|

Melting Point (℃) | 1760 |

|

|

Temperature Limit of Insert | Glass 650℃ |

Stainless Steel 1100℃ | |

|

|

Color | White |

|

|

Fiber Diameter (µm) | 3-4 |

|

|

Loss on Ignition (%) | 18 |

|

|

Thermal Conductivity(W/m.k) 1000℃ | <0.18 |

|

|

Linear Shrinkage 24hrs (%) 1100℃ | 3 |

|

|

Chemical Composition (%) |

|

|

|

Al2O3 | 47-49 |

|

|

Al2O3+ SiO2 | 99 |

|

|

Fe2O3 | 0.2 |

|

|

K2O+Na2O | 0.2 |

- Q: What is the function of (ceramic) ceramic powder?

- In the process of porcelain fused to metal (PFM), the powder material used for sintering and making ceramic restoration is made. There are long stone and alumina ceramic powder, as well as a variety of crystal reinforced porcelain powder, high temperature porcelain powder and low temperature porcelain powder.

- Q: Is everybody's ceramic fiber cloth poisonous?

- With aluminum, zinc and other non-ferrous molten metal erosion capacity. Excellent high temperature strength. The bottom heat conductivity makes the product have good heat insulation performance. Excellent electrical insulation performance. Non-toxic, harmless, no adverse effects on the environment, excellent tensile properties.

- Q: Can ceramic fibers be spun?

- The utility model can also achieve higher strength by increasing metal wire reinforcement, and finally can be made into products such as yarn, cloth, belt, rope, packing, etc., and the utility model has wide application.

- Q: What are the uses of ceramic fiber blankets?

- The ceramic fiber blanket has a strong resistance to wind erosion, and can be directly contacted with flame and high-speed airflow. Because of its excellent fire resistance, high temperature stability, high thermal shock resistance, low heat capacity and high temperature conditions, high compressive strength.

- Q: What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- Ceramic fiber cloth, stainless steel wire, enhanced use temperature of 1050 degrees, glass fiber reinforced use temperature of 650 degrees.

- Q: What are the differences between digital textile printing ink and printing ink?

- The advantages of ink-jet printing methods are: the traditional printing plate making process is omitted, shorten the process and reduce the cost; reduce the dye waste to obtain environmental friendly; digital image to facilitate the design and innovation of small batch flexible production and other traditional printing incomparable advantages.

- Q: What are the man-made fibers polluting the environment?

- Fibers are roughly divided into natural fibers, man-made fibers, and synthetic fibers[natural fiber] refers to the natural growth or formation of fiber, including plant fiber (natural cellulose fiber), animal fibers (natural protein fiber) and mineral fiber. Plant fibers include: seed fiber, phloem fiber, leaf fiber, and fruit fiber. Seed fiber is the unicellular fiber that grows from the epidermal cells of some plant seeds. Such as cotton, kapok. Bast fiber is a single fiber or process fiber obtained from the phloem of some plants. Such as: linen, ramie, jute. Leaf fiber is the process fiber obtained from the leaves or sheaths of some plants. Such as: sisal, abaca. Fruit fiber is the fiber obtained from the fruit of some plants. Coconut fiber. An animal fiber (natural protein fiber) that includes hair, fiber, and gland fibers. Hair follicles: fibers of the hair follicles that have multicellular structures and are composed of keratin. Such as: wool, cashmere, camel hair, rabbit hair, Ma Haimao. Silk fibers: fibers formed from the glands of some insects, especially those produced by lepidopteran larvae, and fibers formed by secretions of some mollusks. Such as: silk.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper

- 1. appearance. The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.2. density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.3. thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.4. stand erect. Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. Ceramic fiber cloth is like the fabric used in our 5. lives. It's soft and doesn't stand upright.6. tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q: Which is better, ceramic fiber or spray velvet?

- With the blowing of thrown silk cotton is two kinds of refractory ceramic fiber cotton cotton in the market at present, according to different production process is defined. Because of the different process, the characteristics of the two kinds of fire-resistant cotton are also different. According to different characteristics, they are applied in different heat insulation fields respectively. Ceramic fiber cotton, also known as aluminum silicate fiber cotton, its main purpose is to use other forms of refractory products, production and processing of raw materials.

- Q: Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Organic glass comes from English Organic Glass. In recent years, in some areas the sheet is made of transparent plastic all are called organic glass, actually this is wrong, it refers to pure acrylic polymethylmethacrylate (PMMA) and the PMMA sheet material, called acrylic plate.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Asia;America; Africa; Europe; and so on |

| Company Certifications | Quality management system certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 21-50 pepole |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | About 230,000 square meters |

| No. of Production Lines | 37 lines |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ceramic Fiber Textiles Twisted Rope

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 40 Rolls kg

- Supply Capability:

- 10 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords