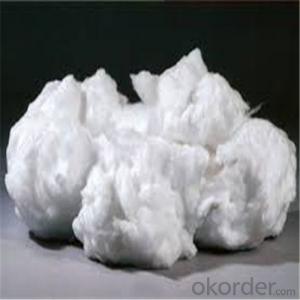

High Temperature Density Ceramic Fiber Bulk

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | HP (High Pure) | Application: | Refractory | Thickness: | 10/20/25/30/50mm |

| Width: | 610/1220mm | Length: | 7200/5800/3600/3000mm | Chemical Composition: | Al2O3 46%,Aluminium Silicate |

| Ultimate Strength (≥ MPa): | 0.08-0.12Mpa | Working Temperature: | 950°C-1350°C | Fiber Diameter: | 3-5μm |

| Shrinkage (1800 ℉, 3h): | ≤-3(24 hours) | Thermal Conductivity: | 0.09-0.16w/m.k(400-800C) | Density (kg/m³ ): | 128 |

| Model Number: | JQ | Brand Name: | Place of Origin: | (Mainland) | |

| Color: | Pure White | Density: | 96/128/160kg/cm3 | Certificate: | MSDS |

| Fe2O3 content(%): | 0.4% | Package: | Carton |

Packaging & Delivery

| Packaging Detail: | Package:Carton Carton size:460*460*620mm |

| Delivery Detail: | Within two weeks |

Specifications

1:JQ ceramic fiber blanket

2:Density :96/128/160kg/cm3

3:Working temperature :950-1350 degree

4:MSDS certificate

Ceramic Fiber Bulk

Production Technology

Blown-fiber blanket, made of common, high pure, high aluminium and zirconium alumina silicate fiber bulk produced by blowing fiber forming technology, has undergone several processes including needling, thermal forming, vertical and transverse slitting and rolling. In addition to the same excellent performance of corresponding bulk aluminum silicate fiber bulk, various kinds of needled blankets have solid tensile strength.

- Q: What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Energy saving: ordinary furnace heat loss, heat rate, furnace insulation can. The holding time of ceramic fiber furnace is ten times higher than that of ordinary furnace, and it is easy to quench and quench.

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density in 200-220, the first production of ceramic fiber module is generally made of ceramic fiber blown blanket, fiber blown blanket fine short, ceramic fiber module is made out of the expansion is relatively stable, but in recent years because of the cost of production, the majority of ceramic fiber module are thrown silk do relatively, the tensile force is big, according to your own combustion atmosphere of furnace temperature and heating module and intracranial, select the density and thickness of the ceramic fiber module. Just make the insulation layer, then recommend 200kg/ cubic meters. Ring fire-resistant insulation materials company has a specific index and design analysis.

- Q: Should the ceramic fiber furnace be compacted?

- In view of the large industrial furnace, the ceramic fiber module can be chosen to be refractory, heat insulated and insulated, and the ceramic fiber module is firmly fixed on the furnace wall by the parallel mounting method, which is more reliable

- Q: Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Three kinds of materials are heat insulation materials, applications and temperature resistance is different.Glass fiber cotton is a kind of excellent performance of inorganic non-metallic materials, variety, has the advantages of good insulation, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage is brittle, poor wear resistance, the maximum temperature of four less than Baidu.

- Q: Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- 1, general masks, gauze, masks, etc., can not be used as dust masks.2, mask must pass GB 2626-2006 standard certification.3, it is recommended to choose N100 class dust masks.4, individual suggestions according to choose different shapes masks.5, it is recommended to change the filter gauze mask. Material recommended for silicone material.Through the above way, it can effectively prevent pneumoconiosis.

- Q: Is the ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..Landlord, it seems that this material is non-toxic, rest assured that the use of good.

- Q: Is aluminum silicate fiber poisonous?

- Hello, silicate in the stomach and stomach acid reaction, forming insoluble silicic acid. There should be no toxicity.

- Q: The difference between the ceramic fiber blanket and rock cotton blanket

- Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminum silicate needle carpet should be aluminum silicate needled blanket, with the continuous production, by acupuncture fiber uniformity, high tensile strength, does not contain any additives. Ceramic fiber, also known as aluminum silicate fiber, is only a different name.

- Q: Ceramic fiber material fire shutter door how many square?

- Now there are two kinds of rolling to use ceramic fiber: a called inorganic super fire shutter (commonly known as the double track curtain), the curtain surface is glass fiber cloth + ceramic fiber cloth + ceramic fiber blanket + aluminum foil cloth, one is WFJ (glass fiber cloth + ceramic fiber cloth + glass fiber cloth).

Send your message to us

High Temperature Density Ceramic Fiber Bulk

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords