Ceramic Fiber Board - Years of History Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Products

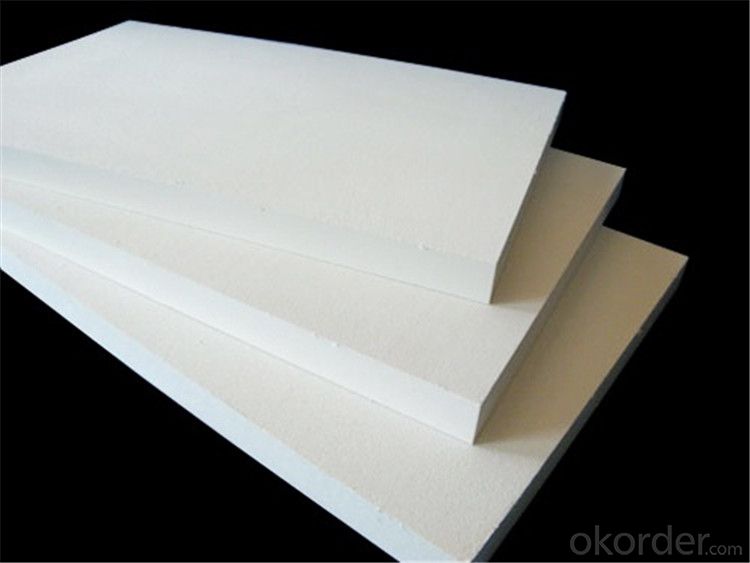

Ceramic fiber board is made of high purity ceramic fiber by adding some binders. Ceramic fiber is a new type of insulating material which contains no asbestos, is eco-friendly and has no cancer-producing effect. Ceramic Fiber Board is made through automation control and continuous production process. Except all the advantage of ceramic fiber bulk it has many other merits, such as solid texture, wind erosion resistance, excellent tenacity etc. It is an ideal material for building tunnels, furnace and many other insulating types of equipment.

Item | Ceramic fiber board |

Size and Specifications | Length: 1200,1000,900mm Width:1000,600mm Thickness:6,10,12.5,25,38,50mm |

Characteristics | (1) low heat capacity and low thermal conductivity (2) good elasticity (3) long service life and excellent thermal shock resistance (4) even fiber distribution and stable performance (5) easily moded or cut (6) accurate size and good flatness |

Typical Use | (1) Iron and steel industry: All heat treatment furnace lining, expansion joints, backing insulation, thermal insulation and mold insulation, steel mill ladle, tundish, ladle and refined ladle back linings. (2) Non-ferrous metals industry: Firebrick back lining for tundish, slot cover and aluminum plant electrolytic reduction cell. (3)Ceramics industry: lightweight kiln car structure and the furnace hot face lining, separation and fire position for all kiln temperature zones; (4) Kiln construction: Hot surface refractories, heavy refractory back linings, expansion joints. (5) Light industry: Industrial and household boiler combustion chamber lining (6) Petrochemical industry: as high-temperature furnace hot surface lining material (8) Craft glass: As craft glass or other deep-processed and molded products mold (9) Cement and construction materials: furnace back thermal insulation lining |

Operating Temperature | 1050 °C |

Service | the specifications of the paper could be customized |

MOQ | 1 piece |

FOB price | 1.15-2.5USD/kg |

Port | Qingdao Port |

Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Cash |

Packing | inner plastic bags+ outer carton box |

Delivery | Within 15 Days |

Certificate | MSDS, CE, ISO 9000 |

Product Details

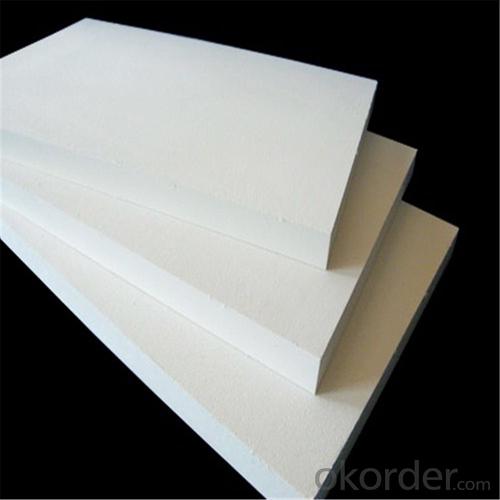

We are one of the few manufacturers who can make ultra-thin ceramic fiber board.

We are one of the few manufacturers who can make super large ceramic fiber board.

We have 23 ceramic fiber production lines to guarantee a punctual delivery.

Main Technical Property Indexes of Ceramic Fiber Board:

Temperatures

| 1050 Ordinary Ceramic Fiber Board | 1260 Standard Ceramic Fiber Board | 1260 High-purity Ceramic Fiber Board | 1400 High-alumina Ceramic Fiber Board | 1450 Zirconium Ceramic Fiber Board | |||||||

Hard Board | Polished Board | Hard Board | Polished Board | Hard Board | Polished Board | Hard Board | Polished Board | Hard Board | Hard Board | |||

Operation Temp | 950°C(1742°F) | 1050°C(1922°F) | 1100°C(2012°F) | 1200°C(2192°F) | 1350°C(2462°F) | |||||||

(kg/m3) Density | 250 | 280-450 | ||||||||||

Permanent Linear Change on Heating | 950°Cx24h≤-4 | 1050°Cx24h≤-3 | 1100°Cx24h≤-3 | 1200°Cx24h≤-3 | 1350°Cx24h≤-3 | |||||||

(w/m.k) Theoretic Heat Conductivity Co-efficient | 0.13(600°C) 0.20(800°C) | 0.13(800°C) 0.19(1000°C) | 0.13(800°C) 0.19(1000°C) | 0.12(800°C) 0.20(1000°C) | 0.16(800°C) 0.20(1000°C) | |||||||

Chemical Composition | Al2O3 (%) | 37 | 46 | 47-49 | 52-55 | 39-40 | ||||||

Al2O3+SiO2 (%) | 96 | 97 | 99 | 99 | - | |||||||

ZrO2 (%) | - | - | - | - | 15-17 | |||||||

Al2O3+SiO2+ZrO2 (%) | - | - | - | - | 99 | |||||||

Fe2O3 (%) | ≤1.0 | ≤0.8 | ≤0.2 | ≤0.2 | ≤0.2 | |||||||

Na2O+K2O (%) | ≤0.8 | ≤0.5 | ≤0.2 | ≤0.2 | ≤0.2 | |||||||

Specifications and Dimensions of the Products:

Categories | Typical Size Ceramic Fiber Board |

Ultra-thin Size Ceramic Fiber Board | Large Size Ceramic Fiber Board | |

(kg/m3) Density | 280-450 | 320-350 | 280-400 | |

Common Size(mm) | L x W | 1200x1000;1200x600; 1000X1000;1000X600; 900x600; 600x300 | 900X600X3; 1200X600X(5-10) 1200X1000X(5-10) | 1200X2400 |

Thickness | 10-80 | 3-10 | 10-80 | |

Packing | Inner Plastic Bag + Outer Pallet or Carton | |||

TIPS:

1 We are one of the few manufacturers who can produce ultra-thin size ceramic fiber board, and we are the only manufacturer who can produce large size ceramic fiber board in zibo of Shandong province.

2 If you cannot find the dimensions you want, please do not hesitate to contact us. We will try our best to help you.

WHY CHOOSE US?

Professional ceramic fiber manufacturer. We have being specialized in producing ceramic fiber products for more than 10 years, and all our products are exported.

Guaranteed quality. Our production process conforms strictly to the requirements of ISO9000 quality management system. Quality inspection is carried out in every links of our production.

Sound after sales service. We provide sound after sales service. We provide 24 hours’ consultation service. We are ready to answer your consultations at any time.

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- Fiber board thermal conductivity of ceramic fiber board thermal conductivity information is mainly: ceramic fiber board thermal conductivity, thermal conductivity of ceramic fiber board price, thermal conductivity of ceramic fiber board wholesale, thermal conductivity of ceramic fiber board factory, discusses the protection method of hot plate test principle and method of MDF thermal conductivity and its relation with temperature; and analyzed the test error.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What are the sound-absorbing fiber boards?

- Ordinary materials have sound-absorbing effect, just how much difference. And when it comes to sound-absorbing board, we are only sound-absorbing coefficient of more than 0.3 of the material known as sound-absorbing material.

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board density in conventional 300-350Kg/m over 350Kg/m to fand, fand fireproof plate series.

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Nano ceramic plate for ceramic fiber with insulating board (felt), it is a functional material with excellent properties of aerogel insulation material and has a heat shielding function, adaptation to adhesive and a variety of inorganic elements in high temperature ceramic fiber as reinforcing material, through a special process preparation.

- Q: What are the uses of ceramic fiber boards?

- According to the conditions of use, can be divided into:Fire dragon high purity ceramic fiber fire block HLGX-364DThe dragon high alumina ceramic fiber fireproof plate HLGX-464D

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Ceramic fiber board is aluminum silicate fiber board, a refractory material. Even after heating, good mechanical strength is maintained. The product is a fibrous insulation product that is rigid and has a supporting strength compared to fiber blankets. Features: ceramic fiber board has excellent quality, toughness and strength, besides, it has excellent resistance to wind erosion. The utility model has the advantages of no heat expansion, light weight, convenient construction, and arbitrary shearing and bending. The utility model is an ideal energy-saving material for kilns, pipes and other heat preservation equipment.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber fireproof plate, the density of 350-400Kg/m ceramic fiber board, fand; density above fand 400Kg/m.

Send your message to us

Ceramic Fiber Board - Years of History Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords