Ceramic Fiber Board Factory Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Application: | Refractory | Thickness: | 10~50mm | Width: | mm600*400*10-5;900*600*20-50,OEM offered |

| Length: | mm600*400*10-5;900*600*20-50,OEM offered | Chemical Composition: | Cermic fiber | Ultimate Strength (≥ MPa): | 0.5 |

| Working Temperature: | ST1050,. HP1100. HA1200. HZ1350 | Thermal Conductivity: | 0.085(400C),0.132(800C),0.180(1000C) | Shrinkage (1800℉, 3h): | 1800℉ |

| Place of Origin: | (Mainland) | Model Number: | 1000-1430Celsius Board | Brand Name: | |

| Grade:: | COM,ST,HP,HAA, HZ | Density:: | 96~160 | Last Annual Turnover: | USD7,500,000 |

| Owing C/O: | Yes | Owing Export Right: | Yes | Business Type: | Manufacture & Exporter |

| Standing Temperature: | -50~550 degree C |

Packaging & Delivery

| Packaging Detail: | Carton (OEM PACKING OFFERED) |

| Delivery Detail: | within 10 days after deposit |

Specifications

Temperature:1000 ~1430Celsius

Grade: ST. HP. HA. HZ

PRODUCING TECHNOLOGY:

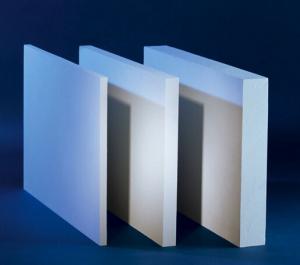

All kinds of ceramic fiber boards,adopting corresponding blowingfibre(ST.HP.HAA.HZ) as the material,are produced by vacuum formed technology. All kinds of ceramic fibre boards,do not only possess the same;function of fibre,but also have hard texture,excellent toughness and intensity,and excellent fire resistant and heat preservation.

WORKING TECHNOLOGY:

Working Temperature is determined by using condition,heating manners and environment atmosphere,etc.

CHARATERISTICS:

Low thermal conductivity, low heat storage

Excellent thermal stability & thermal shock resistance.

Excellent toughness.

APPLICATION COVERS:

Liners of industrial furnace high temperature liner,vehicle,baffle of furnace door,disjunctive board of temperature high temperature equipment insulation,heat preservation. space navigation,ship building,heat insulation fireproofing,sound insulation,insulation

TECHNICAL PARAMETERS:

Item Product | ST | HP | HA | HZ | |

Specification Tem(Celsius) | 1260 | 1260 | 1360 | 1430 | |

Working Tom(Celsius) | 1050 | 1100 | 1200 | 1350 | |

Colour | White | White | White | White | |

Density(kg/m3) | 260 | 260 | 260 | 260 | |

Rate of line(%) (24h,Density320kg/m3) | -3 | -3 | -3 | -3 | |

Rate of thermal | 0.085(400C) | 0.085(400C) | 0.085(400C) | 0.085(400C) | |

Tensilestrengty(Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | |

Chemical composi-tion | AL2O3 | 46 | 47-49 | 52-55 | 39-40 |

AL203+SIO2 | 97 | 99 | 99 | - | |

AL2O3+SIO2+Zro2 | - | - | - | 99 | |

Zro2 | - | - | - | 15-17 | |

Fe2O3 | <1.0 | 0.2 | 0.2 | 0.2 | |

Na2O+K2O | ≤0.5 | 0.2 | 0.2 | 0.2 | |

Size(mm) | Mass Size:600*400*10-5;900*600*20-50 | ||||

WHY CHOOSE US: 1, Manufacture price (8 years manufacture and export experiences)

2, Good made in-house, so to control stable quality & on-time delivery.

3, Formed the Full Products Range

4, Factory close to sea port to save cost

5, ISO 9001:2008 Quality Management system & Company's integrated working system

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- Fiber board thermal conductivity of ceramic fiber board thermal conductivity information is mainly: ceramic fiber board thermal conductivity, thermal conductivity of ceramic fiber board price, thermal conductivity of ceramic fiber board wholesale, thermal conductivity of ceramic fiber board factory, discusses the protection method of hot plate test principle and method of MDF thermal conductivity and its relation with temperature; and analyzed the test error.

- Q: What are the standards for ceramic fiber boards?

- The existing ceramic fiber board has broken through the age of fear of water, and the newly developed hydrophobic ceramic fiber board has the characteristics of normal working under the water environment.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: What are the sound-absorbing fiber boards?

- The theory on the absorption coefficient is the best sound-absorbing board sound-absorbing effect 1 (all suck, no reflections), but in reality, this material does not exist (black holes in the universe are the sound absorption coefficient is 1, which is completely absorbed)

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board density in conventional 300-350Kg/m over 350Kg/m to fand, fand fireproof plate series.

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Nano ceramic plate for ceramic fiber with insulating board (felt), it is a functional material with excellent properties of aerogel insulation material and has a heat shielding function, adaptation to adhesive and a variety of inorganic elements in high temperature ceramic fiber as reinforcing material, through a special process preparation.

- Q: What are the uses of ceramic fiber boards?

- Ceramic fiber board is the main use of heat insulation, fire protection, insulation to use, but also with sound absorption, noise reduction, thermal shock resistance and so on. Ceramic fiber board is mainly used in all kinds of furnace lining insulation, kiln wall lining insulation, metallurgical industry furnace fire, aluminum reduction tank, refractory brick backing.

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- 1, high compressive strength, long service life; 2, low heat capacity, low thermal conductivity;3, non brittle material, good toughness;4, accurate size, good flatness;5 、 easy to cut and install, easy to construct;6, excellent wind erosion resistance;7 、 continuous production, uniform distribution of fiber, stable performance.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board has the characteristics of tough, high compressive strength, excellent resistance to high temperature and excellent supporting force. The compressive strength of ceramic fiber board increases with the increase of density of ceramic fiber board.

Send your message to us

Ceramic Fiber Board Factory Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords