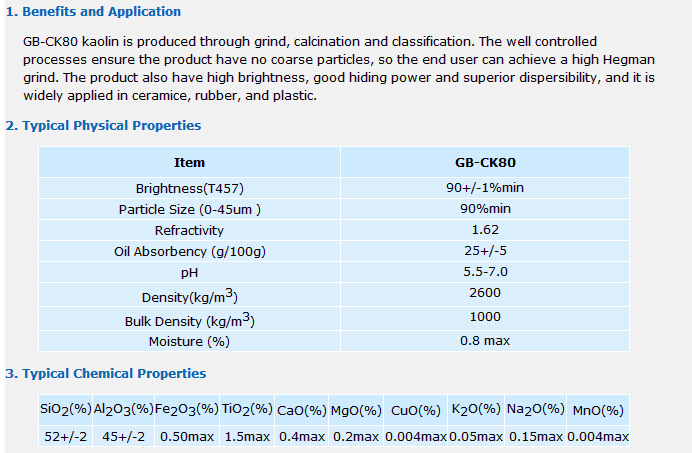

CALCINED KAOLIN FOR CERAMICS (GB-CK80) INDUSTRY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

4.Application

4.Application

- Q: What are the surface modification technologies of calcined kaolin and the matters needing attention?

- Calcined kaolin is a kind of mineral material with high whiteness, large specific surface area, good insulation and good thermal stability, which is calcined, dehydrated and removed volatile substances. Calcined kaolin has excellent chemical corrosion resistance, solvent resistance, acid and alkali resistance and good reinforcing and processing performance, widely used in paints, coatings, paper, rubber and plastic products, cable, ceramics and other industries.

- Q: The difference between kaolin and high white mud

- Pure kaolin is characterized by high whiteness, soft quality, easy dispersion, suspension in water, good plasticity and high cohesiveness, and excellent electrical insulation performance;

- Q: What are the requirements for kaolin as refractory material, such as how much aluminum is needed?

- Kaolin as refractory material actually plays two roles, one is to improve refractoriness, and two is to improve the body plasticity of refractory material

- Q: Process characteristics of kaolin

- Whiteness is one of the main parameters of kaolin's technological properties. Kaolin with high purity is white. Kaolin whiteness, natural whiteness, and whiteness after calcination. For ceramic raw materials, the whiteness of calcined is more important, the higher the whiteness of calcined, the better the quality. The ceramic process stipulates that the drying temperature is 105 degrees centigrade and the classification standard is the natural whiteness. The calcined 1300 DEG C is the grading standard for the whiteness of the calcined products. Whiteness can be measured by a whiteness meter. Whiteness meter is a measure of a 3800 - 7000 (i.e., 1 =0.1 nm) wavelength of light reflectivity of the device. In the whiteness meter, the reflectivity of the sample to be measured is compared with the reflectance of the standard sample (such as BaSO4, MgO, etc.), i.e., the whiteness value (such as whiteness 90, which represents 90% of the standard sample reflectivity).

- Q: What is the best composition of kaolin?

- Some trace metal elements which may be a different color, the specific color and the metal or metal oxide flame color color

- Q: Application of kaolin

- Kaolin has become the mineral material necessary for papermaking, ceramics, rubber, chemicals, coatings, pharmaceuticals and national defense.Ceramic industry is the earliest and larger amount of kaolin. The general dosage is 20% to 30% of the formula. The role of kaolin in the ceramic is conducive to the introduction of Al2O3, mullite, the chemical stability and sintering strength during sintering kaolin decomposition of mullite, the main frame form body strength, can prevent the deformation of the product, the firing temperature becomes wide, can make the body with whiteness some. At the same time, kaolin has a certain degree of plasticity, adhesion, suspension and binding capacity, given the enamel porcelain clay, good formability, the ceramic clay for car billet and grouting, easy forming. If used in an electric wire, insulation can be increased and dielectric loss is reduced.

- Q: What's the requirement of high-grade kaolin?

- Kaolin is mainly aluminosilicate, the main component of AL2 (Si2O5) (OH) 4, or written as Al2O3 2H2O 2SiO2,Some trace metal elements which may be a different color, the specific color and the metal or metal oxide flame color color.

- Q: What is the role of kaolin in plastics? What's the role of kaolin in plastic formulations?

- The role of calcined kaolin is filler, not the color of paint, hiding force plays an obvious role, but only increase the solid componentIncrease weight.

- Q: Is kaolin poisonous? What is kaolin?

- Kaolin is a nonmetal minerals, the Baidu encyclopedia can know, no toxic poison, this is to say, it is not toxic, but now after a lot of chemical bleaching process, generally acidic, a little.

- Q: Kaolin with magnetic separator, how about iron?

- Kaolin separator iron removal process is dry and wet dressing process method for magnetic separation of magnetite, in iron removal process, it can improve the reuse rate in the process of iron removal process, less water consumption, save water, reduce production costs, reduce pollution, dust and dust removal device with special magnetic separation, not air pollution is a kind of high production efficiency, good product quality, no environmental pollution process of creative.

Send your message to us

CALCINED KAOLIN FOR CERAMICS (GB-CK80) INDUSTRY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches