BWD-400/1300 corrugated sheet automatic molding machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Tile Forming Machine,Tile Roll Forming Machine | Tile Type: | Colored Glaze Steel,colored steel | Use: | Roof |

| Place of Origin: | Shanghai China (Mainland) | Brand Name: | kejo | Model Number: | it's up to you |

| Certification: | CE ,ISO 9001 | Color: | as require | Control system: | PLC |

| Name: | Corrugated Sheet Roll Forming Machine |

Packaging & Delivery

| Packaging Detail: | 40 feet container |

| Delivery Detail: | 30 days after receiving down payment |

Specifications

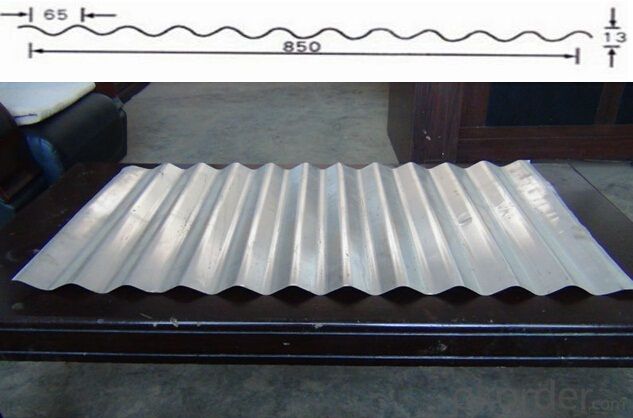

1)corrugated sheet roll forming machine

2)thicknes:0.5-0.6mm

3)width:1250 mm

4)control:PLC

5)certification: CE,ISO9001

Detailed Product Description

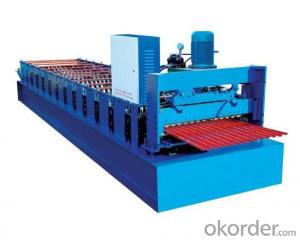

Corrugated Sheet Roll Forming Machine:

This roll forming machine is the special equipment for continuous rolling and cold-forming on steel sheet. It adopts coiling steel sheet as the raw material, decoiling the coil, continuous rolling and cold-forming. automatically cut to the size and output the finished panel. The equipment adopts PLC control, AC frequency and adjusting the speed technology, and it realizes the continuous automatically production.

1 .Working Flow:

Decoiling ---- guiding----roll forming---- punching----cutting---- supporter

2.Technical Parameters:

NO. | Item | Parameter | Remark |

1 | Material | color coating steel sheet | according to buyer's requirement |

2 | Thickness | 0.5 - 0.6 mm | according to buyer's requirement |

3 | Coil width | 1250mm | according to buyer's requirement |

4 | Working speed | 3.0 - 4.0m/min | including punching |

5 | Roller material | No.45 steel | |

9 | Controlling system | PLC | |

10 | Type of cutting | hydraulic | according to buyer's requirement |

13 | Voltage | 380V 3 phase 60Hz or at | according to buyer's requirement |

- Q: What are the shortcomings of traditional machining?

- Machined parts after each done should have a traceability of the unique identification number, the identification number is the identity of the ID card, identification number should have a unified coding rules,

- Q: Information on building materials decoration.

- Equipment Construction Projects Cooperation Adhesives Metal Building Materials Insulation Materials Building Materials Door and Window Wall Materials Wood Sheet Other Building Materials Products Construction Materials Stone Stone Lime, Gypsum Plastic Building Materials Locks Ceramic Processing Machinery

- Q: Information on building materials decoration.

- products special building materials ceiling paint culture stone processing machinery brick, tile and block decoration building materials agent operating reference:

- Q: Classification and components of hydraulic press

- According to the application of equipment, hydraulic equipment can be divided into many types, such as machine tool hydraulic equipment, plastic molding processing hydraulic equipment, engineering machinery hydraulic equipment, steel metallurgy hydraulic equipment, building materials processing hydraulic equipment.

- Q: Mechanical processing technology to mechanical product design, specifically to prepare what?

- Do the design to lay the foundation: skilled use of design software, design products and the actual convergence (production costs, easy to use, security, etc. should have a specific audit).

- Q: Main classification of hydraulic machinery?

- (3) according to the degree of precision equipment according to the degree of precision, hydraulic equipment can be divided into precision equipment and general equipment.

- Q: What gear is machined out of the gear?

- The bevel gears are laid on the planer. Spiral bevel gears - forming end mills.

- Q: What is the principle of the cutting order in machining?

- ③ the first main after the first processing of the main surface, and then processing the secondary surface.

- Q: What are the aspects of the mechanical processing quality

- Mechanical processing, machine tools, fixtures, knives and workpieces constitute a complete system, known as the process system. The machining error is due to the fact that there are many error factors in the process system before and after processing, collectively referred to as the original error. The original error of the process system mainly includes:

- Q: What are the oyster processing companies?

- Processing industry is divided into two categories: 1 finished product processing: building materials processing drugs processing sports products processing environmental protection equipment processing energy products processing shoe materials, shoe processing medical equipment processing audio and video products processing instrumentation processing industry special equipment processing hardware tools processing jewelry processing apparel Processing of finished shoes processing spray processing stone processing bamboo processing paper processing electronic processing including | patch processing plug-in processing bonding processing electronic assembly processing welding proc

Send your message to us

BWD-400/1300 corrugated sheet automatic molding machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches