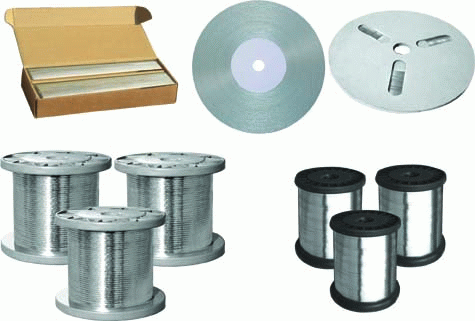

Bus Ribbon -Manual Welding,0.25*8m

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure

We produce custom engineered solar tabbing and bus wire helping to attain the highest efficiencies possible for each unique module design. Our Research and Development team can assist you with your needs evaluation and our world-wide manufacturing facilities are strategically located for large volume production.

Feature

1,Good solderability

2,Good straightness

3,Low yield strength

4,Low Melti

The Flux should be compounded and processed in such a manner as to be uniform in quality and should be free from deleterious material and other details that will after life serviceability or appearance.

Cold Rolling Mills for manufacturing Photovoltaic (PV) Ribbon:

Cold Rolling Mills for manufacturing Photovoltaic Ribbon

This machine is for making Bare flat copper conductors which is using PV Ribbon Wire , Tinned plated flat copper conductors which is using FFC or materials and it was designed to make the best quality products with high productivity as well as easy to control.

Machine capacity

Tinned plated flat copper conductors which is using FFC

Images

Specifications

Visual Inspection

The visual inspection is using perception to inspect the PV Ribbon Wire. The important

aspect of this inspection is the coated copper must free from:

1).Whether or not there is any flaw is checked.

2).Whether or not its surface has uniform lustrous hue be inspected.

3).Whether or not its surface free from thick.

Coating Thickness Test

The measurement to PV Ribbon Wire is using the external micrometer (0. 001mm)or its equivalents.

The test piece of about 250px long shall be taken and the OD of the wire shall be measured at

3 points.Each point shall be measured 2 times

Thickness Of Solder Coated Wire.After the 3 points of wire be measured,dip the test piece into nitric acid for about 5 minutes,the diameter of core wire shall be measured. One half of the two measurements will give the thickness of solder coated wire.

*Recommended temperature of soldering iron tip : 280~320°C

( According to different thickness, adjust the suitable temperature of soldering )

FAQ

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q:Can we visit your factory?

A:Surely, I will arrange the trip basing on your business schedule.

Q:Which payment terms can you accept?

A:T/T,L/C,Moneygram,Paypal are available for us.

- Q: What is the difference between photovoltaic products and solar energy?

- At the same time, the solar photovoltaic power generation system, which is centralized, such as large northwest ground photovoltaic power system; one is distributed (divided by >6MW), such as building roof photovoltaic power generation system of industrial and commercial enterprises, residential roof photovoltaic power generation system.Solar photovoltaic effect, referred to as photovoltaic (PV), also known as the photovoltaic effect (Photovoltaic), refers to the uneven illumination of semiconductor or semiconductor and metal parts of the potential difference between the phenomenon of.Photovoltaic is defined as the direct conversion of ray energy. In the practical application, it usually refers to the conversion of solar energy to electric energy. Its implementation is mainly through the use of silicon and other semiconductor materials made of solar panels, the use of light to generate direct current, such as our daily lives can be seen everywhere in the solar cell.

- Q: Product category and comparison of solar thermal utilization

- What is the reason?The main reason is that China's solar energy (water heater) is the most in-line vacuum tube solar water heater, vacuum tube itself is vulnerable, tube explosion caused by vibrations, icing, improper water and other reasons, the vacuum tube fouling phenomenon is very serious, affecting the normal use, needs a great amount of customer service service, high maintenance costs. Once, encountered bad weather, frequent accidents, too busy to attend to all enterprises and dealers.Where is the way out?According to the experience and lessons of foreign countries, the use of a new type of high-performance flat solar energy is the most feasible and effective solution.

- Q: How to promote the use of solar energy in China

- Overall, the use of solar energy is still very fast, or how the United States will be on China's solar energy products to ban it? As for the overall development of the domestic solar energy industry is good, but still need to do a lot of work. For example, how to improve the quality, efficiency, etc..

- Q: In the domestic high temperature solar energy collector can achieve how many degrees, the existing product and the technology form?

- Solar thermal power can be divided into three categoriesTrough system, tower system and dish system, they all belong to medium and high temperature system,Trough system is relatively popular in the other two categories, but also the most promising class. Operating temperature of 400~700 degrees Celsius, the scale is not limited to a few dozen megawatts, up to the level of Gigabit, there are some examples of successful commercial operation abroad. There are many prototypes in China, but there is no practical system.

- Q: What is the future of solar power

- The roof of photovoltaic power generation is less than 2 million monthly sales tax, in accordance with the provisions of the national taxation policy, power users need to provide sales invoices to the power supply enterprise, the buyer also need invoice offset the cost, and the personal power does not have the qualification of business owners, led by invoices complicated procedures. More than 20 thousand of the tax can not get the invoice, it increases the difficulty of the sales of power generation households, is not conducive to promotion. The State Administration of Taxation issued, will reduce the tax burden on household electricity." According to the State Administration of taxation documents, since July 1, 2014, the national Power Grid Corp to buy power products distributed photovoltaic power generation project, by the national Power Grid Corp invoices, monthly household electricity generating sales of more than 20 thousand products, owned by the national grid enterprises in accordance with the taxable amount of the 50% generation of vat. The monthly sales of less than 20 thousand yuan may be exempt from vat. According to the State Administration of taxation policy released last year, from October 1, 2013 to December 2015 3l, according to the 3% levy rate calculation. In Takamatsu as an example, if a month sales of 30 thousand, that he should pay the tax is 30 thousand x 3% x 50%=450 yuan.

- Q: How much does it cost to install solar energy in rural areas

- Four look at the brand, service. The solar water heater host outdoors year-round by professionals need to withstand exposed to wind and rain, maintenance, maintenance. At present, there are 4000 domestic solar water heater factory, as the country has not yet unified solar water heater testing standards, some of the quality of the product does not pass, installation services are not in place, to bring trouble to users. Buy solar energy is not only a product, but more importantly, service". Therefore, we should choose the strength of the brand name of professional manufacturers of products, such manufacturers to install service personnel are generally through professional and technical training, service and thoughtful, so that you do not worry, get the best protection.

- Q: Solar derived products The role of solar panels is to convert solar energy into electrical energy, the output of DC stored in the battery

- 1 natural circulation:This type of storage tank is placed above the collector. Water heating collector in solar radiation temperature rise, causing the collector and tank water temperature and have a different density difference, thus causing buoyancy, this is like a hot siphon, the water flow in the water storage tank and collector. Because of the density difference, the water flow rate is proportional to the solar energy absorbed by the collector. This kind of type is widely used because it does not need the circulating water and the maintenance is very simple.2 forced circulation:The water in the hot water system makes the water circulate between the collector and the water storage tank. When the water temperature at the top of the collector is higher than the water temperature of the bottom of the water storage tank, the control device can start the water to make the water flow. A check valve is arranged at the entrance of the water to prevent the nighttime water from being driven by the collector to cause heat loss. The flow rate of this type of hot water system can be known (as a result of the flow from the water), easy to predict performance, can also be calculated in a number of hours of heating water. As in the same design condition, the natural circulation has can gain higher water temperature strengths, but because it must use water, the water power and maintenance (such as Water Leakage etc.) and the control device of dynamic stop, damage easily water problems. Therefore, in addition to large hot water system or the need for a higher water temperature, the forced circulation, the general use of natural circulation water heater. Solar power system consists of solar cells, solar controller, battery (group). Such as output power for AC 220V or

- Q: Good solar polymer or monocrystalline

- Spark solar energy products are also exported to many countries and regions such as Italy, Hongkong, Taiwan, the United States, Japan, Korea, Germany and other regions. After years of continuous development and improvement, not only to ensure good quality requirements, and won the domestic and foreign business partners to praise and affirmation. Stand on your point of view the factory must promise: fast delivery! Quality assurance! Price service is good. This season can undertake a large number of solar panels. This product can be customized for the price can also be agreed! Welcome to inquire or visit our company to discuss cooperation!

- Q: What about solar products?Solar panels solar panels

- Solar modules on the equivalent of a battery, what the use of their own to think about

- Q: The steps of making solar technology stubs

- 1 with a brush clean eraser material: big eraser, waste brush.Tools: scissors, glue.

Send your message to us

Bus Ribbon -Manual Welding,0.25*8m

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords