Building Lifter SC100/100 Twin Cage for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of SC100/100 Building Lifter Description

To serve the increasing demand for highrise construction, we developed the high speed VF hoist, with a max.lifting speed of 96 m/min.

It has the following structure:

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/F control: the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoids slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the energy consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack,pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection, low voltage protection, overcurrent, overload and anti-stalling protection functions.

7. The System applies the special software for hoists developed by our company, making the operation more safe and reliable.

Main Features of SC100/100 Building Lifter

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing.

4. Both domestic and imported driving systems are available.

SC100/100 Building Lifter Specification

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Twin Cage Hoist | No Counterweight | SC100/100 | 2*1000 | 0~60 | 2*3*11 | 2*SAJ30-1.4 |

| SC120/120 | 2*1200 | 0~60 | 2*3*11 | 2*SAJ30-1.4 | ||

| SC160/160 | 2*1600 | 0~60 | 2*3*15 | 2*SAJ30-1.4 | ||

| SC200/200 | 2*2000 | 0~60 | 2*3*15 | 2*SAJ40-1.4 | ||

| SC250/250 | 2*2500 | 0~60 | 2*3*18.5 | 2*SAJ50-1.4 | ||

| SC270/270 | 2*2700 | 0~60 | 2*3*18.5 | 2*SAJ50-1.4 | ||

| SC300/300 | 2*3000 | 0~60 | 2*3*22 | 2*SAJ50-1.4 | ||

| SC320/320 | 2*3200 | 0~60 | 2*3*22 | 2*SAJ50-1.4 | ||

| With Counterweight | SCD200/200 | 2*2000 | 0~60 | 2*2*15 | 2*SAJ40-1.4 | |

| SCD250/250 | 2*2500 | 0~60 | 2*2*18.5 | 2*SAJ50-1.4 | ||

| SCD270/270 | 2*2700 | 0~60 | 2*2*18.5 | 2*SAJ50-1.4 | ||

| SCD300/300 | 2*3000 | 0~60 | 2*3*15 | 2*SAJ50-1.4 | ||

| SCD320/320 | 2*3200 | 0~60 | 2*3*15 | 2*SAJ50-1.2 |

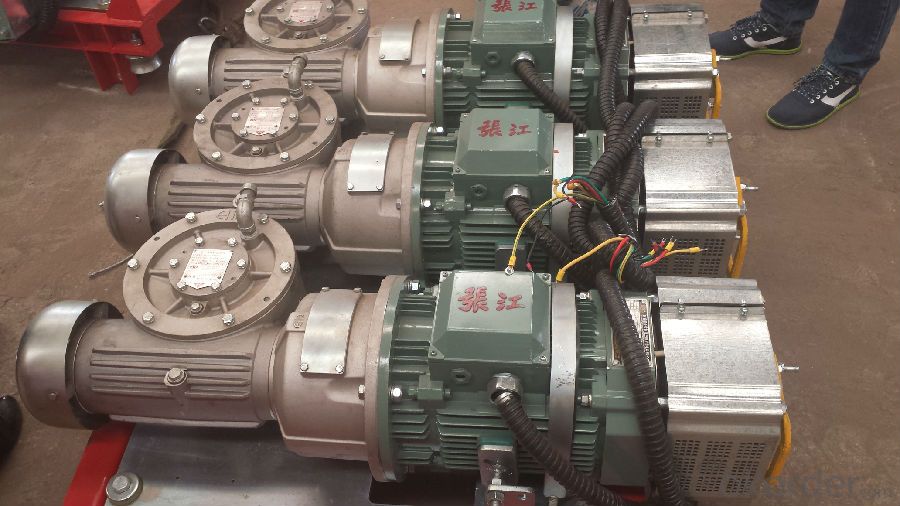

Images of SC100/100 Building Lifter

FAQ of SC100/100 Building Lifter

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for the distinctions between two types of construction equipment: a building hoist and a lifting platform.

- <p>A building hoist, also known as a construction hoist, is a temporary elevator used in the construction of high-rise buildings to transport workers, materials, and equipment up and down the building. It is typically installed on the exterior of the building and is designed for vertical transportation. On the other hand, a lifting platform is a type of aerial work platform that can be either mobile or stationary and is used to lift workers and tools to a specific height for maintenance, repair, or construction tasks. Lifting platforms are often used for outdoor tasks and can be mobile, allowing them to be moved around a worksite as needed. The main difference lies in their application: building hoists are for vertical transport within a structure, while lifting platforms provide height access for a variety of tasks.</p>

- Q: This question asks for the cost associated with purchasing and installing a building hoist.

- <p>The cost of buying and installing a building hoist can vary significantly depending on several factors. The type and capacity of the hoist, the height of the building, and the complexity of the installation are key determinants. On average, the cost can range from $10,000 to $50,000 for the hoist itself, with installation costs potentially adding another 20-50% to the total. However, for very tall buildings or specialized hoists, the price can exceed $100,000. It's crucial to obtain quotes from multiple suppliers and installers to get an accurate estimate for your specific project.</p>

- Q: This question asks about the measures taken to guarantee the safety and reliability of lifting equipment prior to its use in construction.

- <p>To ensure that lifting equipment is safe and reliable before using it in construction work, several key steps must be taken. Firstly, regular inspections and maintenance are crucial to identify any potential issues or wear and tear. Secondly, all equipment should be thoroughly tested and certified by qualified personnel to meet safety standards. Thirdly, proper training for operators is essential to ensure they understand how to use the equipment safely. Additionally, having a comprehensive safety plan in place, including emergency procedures, can help prevent accidents. Lastly, using equipment from reputable manufacturers and ensuring all components are in good working order are also vital for maintaining safety and reliability.</p>

- Q: This question asks for an explanation on how to operate a winch, specifically in the context of a building hoist.

- <p>To use a winch, particularly a building hoist, follow these steps: Ensure the winch is securely anchored and the cable is in good condition. Attach the load to the hook, ensuring it's balanced. Turn the winch handle clockwise to lift the load; counterclockwise to lower it. Always keep tension on the cable to prevent it from slacking. Use a tag line to guide the load horizontally. Never exceed the winch's load limit. Regularly inspect the winch and cable for wear and tear. Always have a spotter to assist and communicate during the operation. Safety is paramount, so never leave the winch unattended while the load is in the air.</p>

- Q: This question asks about the procedures and practices for regularly maintaining and inspecting a building hoist to ensure its safe and efficient operation.

- <p>Regular maintenance and inspection of a building hoist are crucial for safety and efficiency. It involves daily checks before use, including visual inspections for any visible damage, proper functioning of safety devices, and ensuring the hoist is clean and free of debris. Weekly inspections should focus on the mechanical components, such as gears, cables, and brakes, and checking for any unusual noises or vibrations. Monthly inspections may include more in-depth checks of the electrical systems and the structural integrity of the hoist. Annual inspections typically involve a thorough examination by a certified professional, who will assess the overall condition and safety of the hoist, ensuring it complies with all relevant safety standards. Always follow the manufacturer's guidelines and local regulations for maintenance and inspection schedules.</p>

- Q: What measures should be taken to ensure safety when operating electric-motor powered building hoists?

- <p>When using electric-motor type building hoists, safety precautions include: ensuring all safety devices are in good working order, regularly inspecting and maintaining the hoist, following the manufacturer's guidelines, never overloading the hoist, keeping the hoist and its surroundings clean and free from obstructions, using proper lifting techniques, ensuring the hoist is stable and secure, wearing appropriate personal protective equipment, and training operators on the safe use of the hoist. Adhering to these precautions can significantly reduce the risk of accidents and ensure the safety of workers and the integrity of the construction process.</p>

- Q: Why do you ask the construction elevator to be a certain distance from the structure? Is very close to if not you can not bother to do delivery channel security protection or something, out of the elevator out directly, and attachment should be able to get more easily, to solve. Thank you very much!!

- The distance between the moving parts and the building and the fixed construction equipment shall not be less than 0.25 m. The main thing is to prevent the person from the point of view. For example, workers are on the third floor to look down, hanging cage, where is the result now hanging basket is go down from the fourth floor, if not the 25 cm, likely to brush "cut".

- Q: Explain the differences between electric and electric-hydraulic lifting equipment, highlighting their mechanisms and applications.

- <p>Electric lifting equipment operates on electric motors that directly drive the lifting mechanism, such as in electric hoists or cranes. This type of equipment is known for its simplicity, low maintenance, and precision control. On the other hand, electric-hydraulic lifting equipment uses an electric motor to power a hydraulic pump, which in turn moves hydraulic fluid to operate the lifting mechanism. This type is characterized by high lifting capacity, smooth operation, and the ability to handle heavy loads. Electric-hydraulic systems are often used in applications requiring significant force, such as in heavy machinery and construction equipment.</p>

- Q: Can a single lifting device accommodate variously shaped and sized objects?

- <p>Yes, a single lifting device can often be used to lift objects of different shapes and sizes, provided it has the necessary capacity and adaptability. Adjustable features, such as extendable arms, variable hooks, or specialized attachments, allow for a range of lifting capabilities. However, it's crucial to ensure that the device's weight limit is not exceeded and that it is safe and suitable for the specific object being lifted to avoid damage or accidents. Always refer to the manufacturer's guidelines for the safe operation and weight limits of the lifting device.</p>

- Q: This question asks for the steps or methods to fix a malfunctioning building hoist.

- <p>Repairing a broken building hoist requires a systematic approach. First, ensure the hoist is powered off and disconnected from any power source to ensure safety. Identify the specific issue by conducting a visual inspection and possibly consulting the hoist's manual or a professional. Common repairs include fixing mechanical parts like gears, chains, or cables, or addressing electrical issues like faulty wiring or motor problems. If the hoist's control system is malfunctioning, it may require recalibration or replacement of components. In some cases, worn or damaged parts need to be replaced. Always follow the manufacturer's guidelines and safety protocols. For complex repairs, it's best to consult with a professional hoist technician to avoid further damage or safety hazards.</p>

Send your message to us

Building Lifter SC100/100 Twin Cage for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords