Building Hoist Single Cage/Double cage (Model:SC(D)200, SC(D)200/200)

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 20 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description:

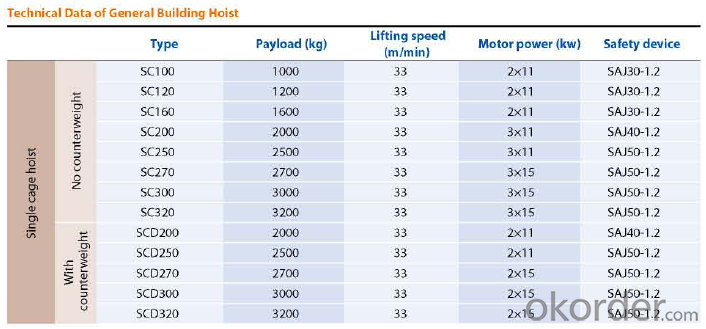

SC building hoist is a vertical transport machinery driving by pinion and rack, mainly used on construction site for transportation of personal and materials. As a permanent or sub-permanent external elevator, it also applies to storehouse, dock, high tower, high chimney, etc.

Feature:

There are single cage and double cages hoist. According to the need, getting rid of one cage of double cages-the hoist will be changed to single cage hoist.

SC building hoist is equipped with reliable electrical and mechanical safety device. It is efficient and safety vertical transporting equipment.

FAQ:

1. There are two types mast section: 450x450x1508mm and 650x650x1508mm

2. Surface treatment: paint or galvanized is available

3. Thickness is 4.2mm and Q345B equal to ST52

4. Our CMAX hoist follow standards of CE

In the past 10 years, CNBM has established over 10 manufacturing base, to offer the one-stop services in construction machinery filed, including R&D, designing, manufacturing, quality control and delivery.

Our product has been exported to more than 100 countries with high customer appreciation & brand popularity.

CNBM provides the full series of construction machinery and one-stop overall solution. Our product range covers pre-fabrication including aggregate crushing, dedusting and block making; concrete series including mixing, batching, pumping & placing; construction series, such as tower crane, building hoist, suspension platform and lifting basket; light construction machinery, including compacting, cutting, surface finishing machines & rebar processing machines.

Especially the concrete placing boom, we’re the No. 1 in term of products variety, with top quality placing boom of placing radius ranging from 10 meters to 51 meters over 10 different series, the excellent quality & performance has been tested & approved by being used in lots of world famous high buildings.

The manufacturing base of CNBM adopts 6S management system. Quality control system are implemented strictly in the whole procedures, including components purchasing, fabricating and manufacturing, packing and dispatch pre-inspection, ensuring the perfect quality assurance for all of our products. With international certificates like ISO9001:2008, CE & SGS, CNBM guarantee the international first-class level for all of our products.

“Quality achieves outstanding success, innovation leads the bright future”, our working principle has leads the rapid expansion of CNBM, with branches and spare parts distribution centers established oversea step by step.

In the coming days, CNBM will continue to forge ahead, make our best efforts to create the best platform for career performance, as well as to realize the maximized mutual benefit with all CNBM friends, partners, agents & clients.

“View Broad, Ambitions Boundless”, at a new height, we wish to join hands with all the ambitious friends together, contributing to the consummation of the first-class quality construction machinery industry, and creating the new glory constantly.

- Q: Is it possible for non-professionals to overhaul or repair a hydraulic cylinder in a building hoist?

- <p>No, a hydraulic cylinder in a building hoist should not be overhauled or repaired by non-professionals. Hydraulic systems are complex and require specialized knowledge and skills to service. Attempting repairs without proper training can lead to serious safety hazards, equipment damage, and potential accidents. It is crucial to have a qualified technician or professional mechanic handle any maintenance or repairs to ensure safety and compliance with industry standards.</p>

- Q: This question asks for a description of the process of using an emergency stop button specifically in the context of a building hoist.

- <p>To use an emergency stop button on a building hoist, first, ensure you are familiar with the hoist's controls and safety features. Locate the emergency stop button, which is typically a red mushroom-shaped button or switch, prominently placed and easily accessible. In an emergency, press and hold the button firmly. This action will immediately stop all hoist functions, including movement and operation. After pressing the emergency stop, evacuate the area if necessary and notify the appropriate personnel to address the situation. Remember, the emergency stop should only be used in situations where immediate action is required to prevent harm or damage. Regular training and drills can help ensure you are prepared to use the emergency stop button correctly and effectively.</p>

- Q: This question asks for the method to determine the maximum weight that a building hoist can safely lift.

- <p>To calculate the weight limit of a building hoist, you must consider several factors: the hoist's mechanical capacity, the strength of the supporting structure, the load-bearing capacity of the cables or chains, and the safety regulations in place. Start by checking the manufacturer's specifications for the hoist's maximum load capacity. Then, ensure the hoist's supporting structure can withstand the weight and the force exerted during lifting. Inspect the cables or chains for any signs of wear and ensure they meet the required strength standards. Finally, adhere to local safety regulations, which often mandate a safety factor below the hoist's rated capacity to prevent overloading. Always consult with a professional engineer or the hoist manufacturer for precise calculations and safety guidelines.</p>

- Q: This question asks for the method to change the angle at which a building hoist operates.

- <p>Adjusting the angle of a building hoist involves several steps. First, ensure the hoist is turned off and disconnected from power sources. Next, locate the hoist's tilt adjustment mechanism, which is typically found at the base or on the mast. This mechanism often consists of a set of bolts or pins that can be loosened to allow the angle to be changed. Adjust the angle by moving the mast or base to the desired position, ensuring it is level and stable. Once the correct angle is achieved, tighten the bolts or pins to secure the hoist in place. Always follow the manufacturer's guidelines and safety precautions when making adjustments to prevent accidents.</p>

- Q: This question asks for measures to avoid accidents that may occur due to the misuse of a building hoist.

- <p>To prevent accidents caused by improper use of a building hoist, it's crucial to follow safety protocols strictly. Ensure all hoist operators are trained and certified. Regularly inspect and maintain the hoist equipment to check for any defects or wear. Never overload the hoist, and always secure the load properly. Implement clear communication procedures among workers, especially when the hoist is in operation. Set up barriers or warning signs to keep unauthorized personnel away from the hoist area. Finally, conduct regular safety drills to prepare for emergencies and reinforce safety practices among the workforce.</p>

- Q: Is it possible to replace a lifting rope in a construction hoist with a regular rope?

- <p>No, a regular rope should not be used as a substitute for a lifting rope in a building hoist. Lifting ropes are specifically designed for heavy-duty lifting and have safety standards to ensure they can withstand the weight and stress. Regular ropes lack these safety features and can break under heavy loads, leading to accidents. Always use the appropriate lifting equipment as specified by safety regulations and the manufacturer's guidelines.</p>

- Q: What is the need for the sc200/200 construction elevator cable?

- The sc200/200 construction elevator cable line should not be below 120 square. Man's ladder 33KW, 5 * 33 = 165KW The tower is 45KW one, 2 * 45 = 90KW The pressure slag welder is estimated to be 25KW Touch welder 1OKW, 5 * 10 = 50KW Other facilities such as mixer, temporary illumination etc. 30KW Total power: 165 + 90 + 25 + 50 + 30 = 365KW One square cable is 5 minus 7A, 380V is 1KW is equal to 2A. That's 730A 730A divided by 5-7 calculates that the cable line should not be less than 120 square.

- Q: Is it possible to utilize a building hoist to transport heavy vehicles?

- <p>Building hoists are not designed to move heavy vehicles. They are specifically engineered for lifting and lowering materials and personnel in construction settings. Their load capacity and structural integrity are not suited for the weight and dimensions of heavy vehicles. For moving heavy vehicles, specialized equipment such as heavy-duty tow trucks or transporters is required, which are built to handle the specific needs and weight of such vehicles.</p>

- Q: This question asks if a building hoist can be utilized in both commercial and residential settings.

- <p>Yes, a building hoist can be used for both commercial and residential purposes. These hoists are designed to lift materials and workers to various levels of construction sites. In commercial settings, they are often used in the construction of office buildings, shopping centers, and other large-scale projects. In residential construction, they are used for multi-story apartment buildings or private homes. It's important to note that the specific type and capacity of the hoist should be suitable for the scale and requirements of the project to ensure safety and efficiency.</p>

- Q: This question asks for a description of the process of using a hydraulic cylinder in the context of a building hoist.

- <p>To use a hydraulic cylinder in a building hoist, first ensure the hoist is properly installed and secured. Connect the hydraulic cylinder to the hoist's power source, typically a hydraulic pump. The pump pressurizes hydraulic fluid, which is then directed into the cylinder. As the fluid enters, it pushes a piston within the cylinder, causing it to extend and lift the load. To lower the load, the fluid is released from the cylinder, allowing the piston to retract. Always monitor the pressure and ensure the system is leak-free for safe operation. Regular maintenance, including checking seals and lubricating parts, is crucial to prolong the life of the hydraulic cylinder and ensure efficient hoist performance.</p>

Send your message to us

Building Hoist Single Cage/Double cage (Model:SC(D)200, SC(D)200/200)

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 20 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords