Building Hoist SC250 drop test operation box for sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):2500

Lifting Speed(m/min):0~60

Motor Power(kw): 3*18.5

Safety Device: SAJ50-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC250

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

Features of Building Hoist

●Due to the strict raw material procurement control system, our drive motors for construction hoist/ building lift /material elevator for bridge/ tower / chimney / building is guaranteed with safe and reliable performance.

●The steel, electrical components, hoist cables, high strength bolts and spare parts are all introduced from well-known international and domestic suppliers.

●Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

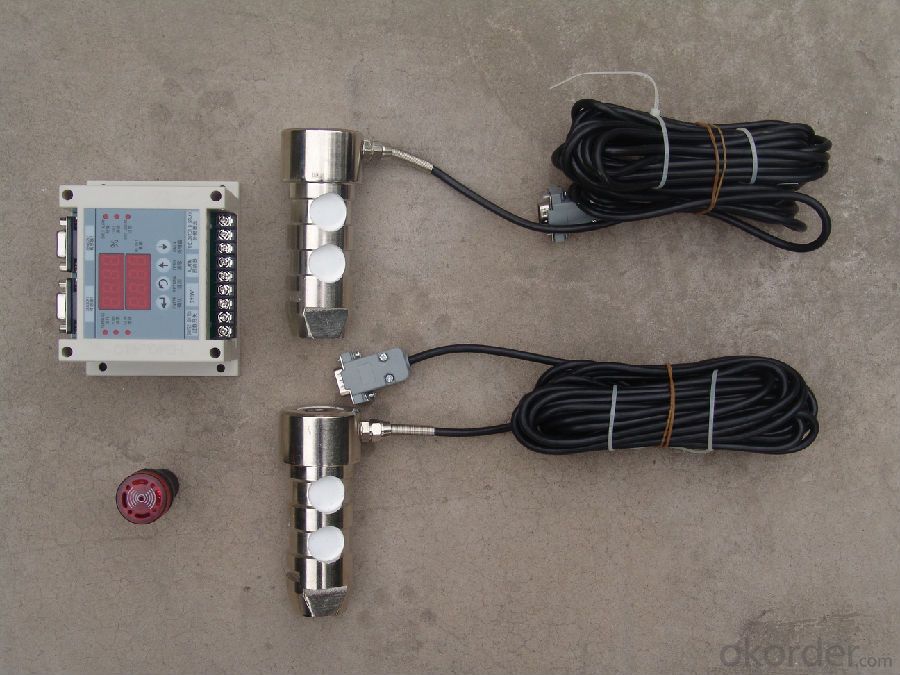

Building Hoist Images

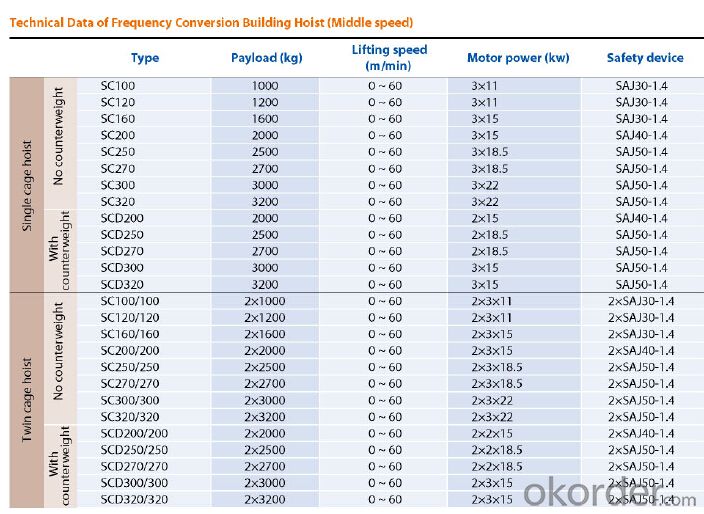

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Is it possible to utilize a building hoist for the purpose of lifting small tools and equipment?

- <p>Yes, a building hoist can be used for lifting small tools and equipment, provided it is within the hoist's weight capacity. It's important to ensure that the items are securely fastened to prevent any accidents during lifting. Always follow the manufacturer's guidelines and safety regulations when using a building hoist for any lifting tasks.</p>

- Q: Excuse me: what is the meaning of heavy weight in the construction elevator?

- That's what it means to be heavyReally, I hope to have more good posts

- Q: How long does the construction elevator do a crash test

- Construction lifter before put into use, must pass a drop test, using every three months should do a drop test, to adjust for safety device, braking distance will be falling not more than 1.2 m, after test and normal operation of every happening for action, must be to reset the attached safety device. The adjustment, repair, or identification of the anti-falling safety device shall be carried out by the manufacturer or designated authorized unit, which shall be operated by the professional at the time of the crash test. General can at the local special equipment inspection institutions detection, can also be tested in other qualified enterprises, such as: wuhan science, Shanghai special survey, qufu golden horse machinery testing!

- Q: This question asks for the process of changing the height at which a building hoist operates.

- <p>Adjusting the height of a building hoist typically involves a few key steps. First, ensure the hoist is powered off and disconnected from any power source to ensure safety. Next, locate the hoist's height adjustment mechanism, which may be a set of bolts or a telescoping column. Loosen any locking nuts or bolts that secure the current height setting. Adjust the hoist to the desired height by raising or lowering the platform or mast. Once the desired height is reached, tighten the locking nuts or bolts to secure the hoist in place. It's crucial to check the manufacturer's guidelines for your specific hoist model, as the process may vary. Always follow safety protocols and consult with a professional if you're unsure about any steps.</p>

- Q: How many people are there for construction workers

- Different models of different sizes, small can multiply 10 people, this time see a big, can take 14 people

- Q: This question asks for a comparison of the benefits and drawbacks of employing lifting equipment in the construction industry.

- <p>Advantages of using lifting equipment in construction include increased efficiency, reduced manual labor, and the ability to handle heavy loads safely. It can also improve safety by reducing the risk of injury from lifting heavy objects manually. Additionally, it allows for faster construction times and can access hard-to-reach areas. Disadvantages include high initial costs for purchasing or renting the equipment, potential for mechanical failure, and the need for skilled operators. There is also a risk of accidents if the equipment is not used properly, and it may require more maintenance and training for staff.</p>

- Q: Explain the key differences between electric and pneumatic lifting equipment in a few sentences.

- <p>Electric lifting equipment is powered by electricity and offers precise control, high efficiency, and is suitable for heavy-duty applications. Pneumatic lifting equipment, on the other hand, is powered by compressed air and is known for its simplicity, safety, and lower cost. It is often used in environments where electrical equipment might be hazardous, such as in the presence of flammable gases or dust. Electric systems can handle heavier loads and provide more precise control, while pneumatic systems are more resistant to overload and offer a fail-safe mechanism in case of air pressure loss.</p>

- Q: This question asks for the cost of a building hoist, which is a type of construction equipment used for lifting materials.

- <p>The cost of a building hoist can vary significantly depending on factors such as the hoist's capacity, type, and features. On average, a basic building hoist can cost anywhere from $10,000 to $50,000. However, for more advanced models with higher capacities or additional safety features, the price can range from $100,000 to $200,000 or even more. It's important to consider the specific needs of your construction project and consult with equipment suppliers for accurate pricing.</p>

- Q: What is the capability of a building hoist in terms of lifting large objects?

- <p>Yes, building hoists are designed to lift and transport large objects in construction settings. They have a high load capacity, often ranging from several hundred to several thousand kilograms, depending on the model and specifications. Building hoists are equipped with safety features to ensure secure lifting and are commonly used for moving materials such as cement, bricks, and heavy equipment within multi-story buildings under construction. However, it's crucial to adhere to the manufacturer's guidelines regarding weight limits and safety protocols to prevent accidents.</p>

- Q: This question asks for a guide on how to properly and effectively install lifting equipment to ensure safety and efficiency.

- <p>To install lifting equipment safely and efficiently, follow these steps: 1. Ensure the equipment is suitable for the load and environment. 2. Check all safety features and documentation. 3. Position the equipment on a stable, level surface. 4. Follow the manufacturer's installation guide precisely. 5. Conduct a thorough inspection before operation. 6. Train operators on safe usage. 7. Regularly maintain and inspect the equipment. Remember, safety is paramount, and adherence to guidelines is crucial to prevent accidents and ensure efficient operation.</p>

Send your message to us

Building Hoist SC250 drop test operation box for sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords