Building Hoist SC100/100 Double Cage South Africa

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):2*1000

Lifting Speed(m/min):0~60

Motor Power(kw): 2*3*11

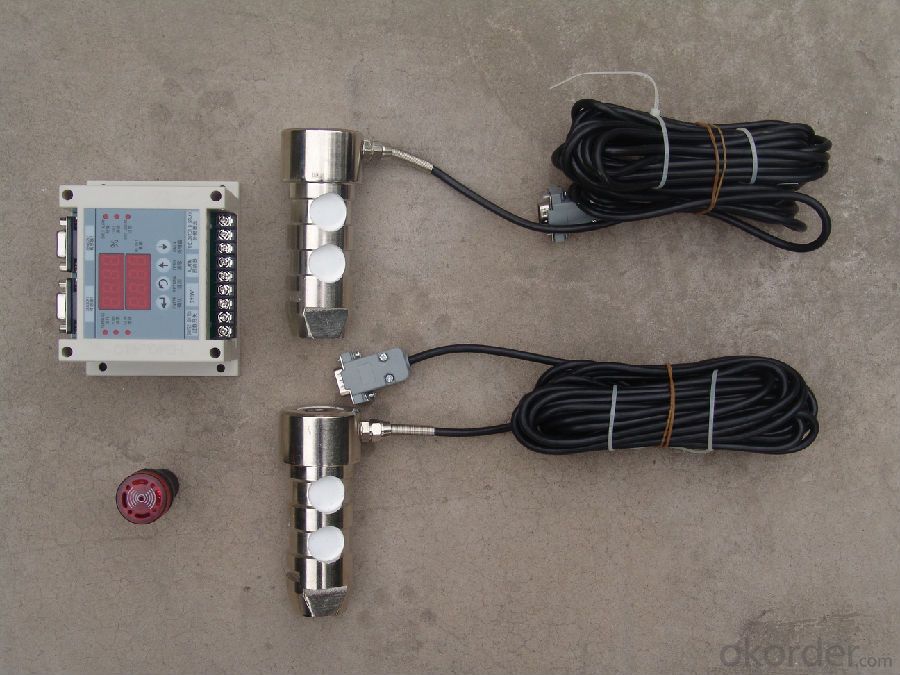

Safety Device: 2*SAJ30-1.4

Cage: Double

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

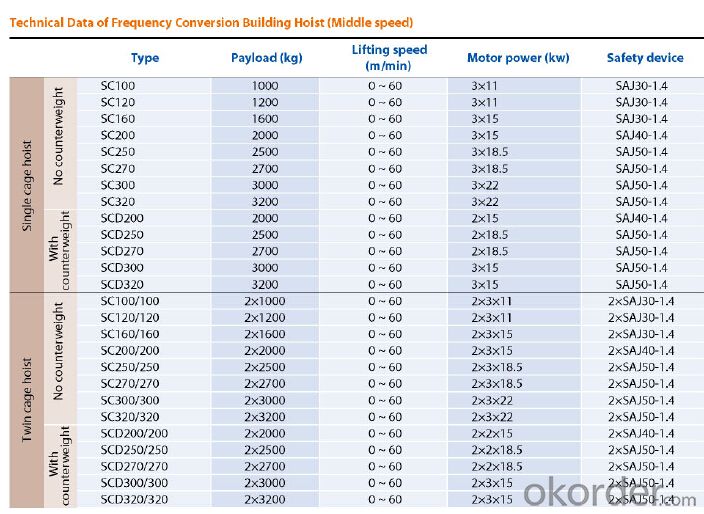

Model Number: Type:SC100/100

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

Features of Building Hoist

●Due to the strict raw material procurement control system, our drive motors for construction hoist/ building lift /material elevator for bridge/ tower / chimney / building is guaranteed with safe and reliable performance.

●The steel, electrical components, hoist cables, high strength bolts and spare parts are all introduced from well-known international and domestic suppliers.

●Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

Building Hoist Images

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Is it safe to use a building hoist for lifting heavy objects when there is wind?

- <p>Using a building hoist in windy weather is generally not recommended due to the increased risk of accidents. Wind can cause the hoist to sway, potentially leading to loss of control and dropping of the load. Safety guidelines typically advise against hoisting operations when wind speeds exceed certain limits, often around 20-30 miles per hour (32-48 kilometers per hour). It's crucial to check local regulations and the manufacturer's guidelines for the specific hoist model to determine safe operating conditions. Always prioritize safety and ensure that all necessary precautions are taken to secure the load and the hoist in windy conditions.</p>

- Q: This question asks for the steps or procedures to keep a building hoist in good working condition.

- <p>Maintaining a building hoist involves regular inspections, lubrication, and repairs. Ensure all safety features are operational and that the hoist is clean and free of debris. Check cables for wear and replace them if necessary. Lubricate moving parts as per the manufacturer's recommendations. Inspect the electrical system for any signs of damage or wear. Regularly test the hoist's load capacity and emergency stop functions. Keep a maintenance log to track all inspections and repairs. If any issues are identified, address them promptly to prevent accidents and ensure the hoist operates safely and efficiently.</p>

- Q: The safety officer shall be responsible for the work of the construction elevator

- Certificate of factory, whether the elevator is inspected by the competent authority, the operator has the evidence. Conduct safety techniques for operators.

- Q: This question asks if building hoists are capable of moving large or heavy objects.

- <p>Yes, building hoists are specifically designed to move large and heavy objects vertically in construction settings. They are used to lift materials such as bricks, concrete, and steel beams to various levels of a building under construction. Building hoists are engineered to handle significant weight and are an essential tool for efficient material transport in tall structures where cranes may not be practical or safe for frequent use.</p>

- Q: This question asks for the different categories of hoists used in construction.

- <p>Building hoists are essential for the construction industry and come in various types. The main types include: 1. Material Hoists, which are used for lifting building materials; 2. Personnel Hoists, designed for transporting workers; 3. Goods and Passenger Hoists, which can carry both materials and people; 4. Temporary Hoists, used during the construction phase; and 5. Permanent Hoists, installed in buildings for long-term use. Each type has specific features and safety considerations tailored to their intended use.</p>

- Q: What are the necessary maintenance tasks and considerations for ensuring the safe and efficient operation of a building hoist?

- <p>The maintenance requirements for a building hoist include regular inspections, lubrication, and checks on all mechanical components. It is crucial to inspect the hoist's cables, pulleys, and brackets for wear and tear. The drive mechanism and safety devices should be tested for proper functioning. Lubrication of moving parts is essential to reduce friction and prevent overheating. Additionally, the electrical system should be checked for any faults or damage. It's important to keep the hoist clean and free of debris to prevent any operational issues. Following the manufacturer's guidelines for maintenance intervals and procedures is vital to ensure the hoist remains safe and efficient.</p>

- Q: This question asks if a building hoist can be utilized for lifting both light and heavy objects.

- <p>Yes, a building hoist can be used for lifting both light and heavy objects. It is designed to handle a wide range of weights, depending on its capacity. Building hoists are engineered to lift materials such as bricks, concrete, and steel beams during construction. However, it's crucial to ensure that the hoist's lifting capacity is not exceeded to avoid accidents. Always check the manufacturer's specifications and safety guidelines before lifting any object with a building hoist.</p>

- Q: Is it possible to utilize a manual building hoist for the purpose of lifting heavy objects?

- <p>Yes, a manual building hoist can be used for lifting heavy objects. These hoists are designed to handle significant weights and are commonly used in construction for moving materials and equipment to various heights. They are operated manually, often with a hand crank or lever, and are equipped with safety features to prevent accidents. However, it's crucial to ensure that the hoist is rated for the weight of the objects being lifted and that all safety protocols are followed to avoid any accidents.</p>

- Q: This question asks for a comparison of vertical and horizontal lifting in the context of building hoists, highlighting their distinct characteristics.

- <p>Vertical lifting in a building hoist refers to the movement of materials directly up or down, which is essential for transporting goods between different floors or levels of a building under construction. Horizontal lifting, on the other hand, involves moving materials across a horizontal plane, which is useful for moving items along a floor or between different parts of a construction site. Vertical lifting is typically more common in hoists due to the nature of building construction, requiring frequent vertical transport. Horizontal lifting is less common but can be implemented with specialized equipment or by combining vertical and horizontal movements. The choice between vertical and horizontal lifting depends on the specific requirements of the construction project and the layout of the site.</p>

- Q: Is it possible to replace an electric motor with a hydraulic cylinder in an electric-hydraulic lifting system?

- <p>No, a hydraulic cylinder cannot be used in place of a motor in an electric-hydraulic lifting system. A hydraulic cylinder is a component that converts hydraulic pressure into linear motion, while an electric motor converts electrical energy into mechanical energy. In an electric-hydraulic system, the motor drives a hydraulic pump, which generates the pressure needed to actuate the cylinder. The motor is essential for providing the power source, and the cylinder is the actuator that uses this power to perform work. Replacing the motor with a cylinder would result in a system without a power source, rendering it inoperative.</p>

Send your message to us

Building Hoist SC100/100 Double Cage South Africa

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords