Building Hoist Hot Galvanizing Mast Section Spare Parts with 3.2ton Capacity

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

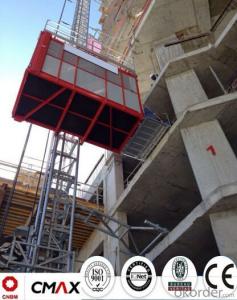

Structure of Building Hoist Description

1.The gearing select perfect bearing,strong cables and oil seal.

2.The electrical parts select products from famous world manufacturers for example Schneider,Siemens and LG.

3.The racks and pinion select advanced material and advanced technique,which enhance the life of all parts.

4.The steel structure adopted strong steel from famous native manufacturers.

5.The surface of the steel structure can adopt paint-spray,parkerizing baking finish or hot galvanizing processing depending on users requirement.

6.The cage can be made and decorated by aluminum molded board,punched-plate or figured aluminum board.

Packaging & Delivery of Building Hoist

Packaging: nude and wooded box Delivery: 25-30days

Mains Parts of Building Hoist

1.The steel structure for example the mast, tie in and cabin ,could be all spay-painted and hot galvanized. Mast section is made with high quality Q345B which is the top standared in China.

2.Electrical parts are all adopted with Schneider , Siemens and other famous brands.

3.The electrical system can be selected with the normal control method and VVVF+PLC control way. Inverter we selected is from Schneider. Yaskawa or other world renowned brand.

4.Cabin exit door select ramping type. The ramping door looks like a bridge between the construction hoist and construction building.

5.The cabin floor is made from 3MM thickness steel riffled board(Hot dip galvanized), and 15MM thickness wooden board which can reduce the vibration and deformation a lot.

6.Driving unit is adopted the products from ZHANGJIANG and other reputed maker, or from SEW, NORD.

7.Safety system is mainly composed of electrical motor braking, anti-drop safety device, top & bottom limit switches, top & bottom 3-phase switches, door limit switches, buffer device and over-load protection. The system aims to ensure the hoist are running safely.

8.Qualification: CE, ISO9001:2008 and etc.

9.The long-term operation of CMAX building hoists testifies CMAX hoist is working performance is stable.

Building Hoist Images

Building Hoist Specification

FAQ of Building Hosit

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for the proper usage guidelines for a building hoist, a mechanical device used in construction to lift materials.

- <p>To use a building hoist correctly, follow these steps: Ensure the hoist is inspected and certified for safe operation. Check all safety devices, including limit switches and emergency stops, are functioning. Securely attach the load to the hoist's hook, ensuring it's balanced and within weight limits. Never exceed the hoist's capacity. Operate the hoist with caution, avoiding sudden starts or stops. Keep the hoist area clear of people and obstacles. Use a tag line to guide the load if necessary. Always lower the hoist when not in use and secure it against wind or other forces. Regular maintenance and inspections are crucial to prevent accidents.</p>

- Q: This question asks whether a building hoist can be utilized in both indoor and outdoor environments for lifting objects.

- <p>Yes, a building hoist can be used both indoors and outdoors for lifting objects. These hoists are designed to handle heavy materials and are often used in construction settings. However, their use is subject to specific conditions and safety requirements. Outdoor use may require additional considerations such as weatherproofing and stability in various weather conditions, while indoor use must adhere to space limitations and structural integrity of the building. Always ensure that the hoist is suitable for the environment and that all safety protocols are followed to prevent accidents.</p>

- Q: Is there a specification requirement for the floor door of the elevator to the floor? How high

- Layer should be made from steel door frame, Shanghai silk screen, and is equipped with solid and reliable locking device, elevator door layer, the process should be hanging cage crew operations, shall not be under the direct control of elevator lift cage's movement. The net height should not be lower than 1.80 m, and the width of the door should not be greater than 120mm.

- Q: The user is asking if it's possible to use a building hoist, typically used for construction, to lift a car.

- <p>Using a building hoist to lift a car is not recommended. Building hoists are designed for lifting materials and equipment in construction settings, not for vehicles. They may not have the appropriate safety features or load-bearing capacity for a car. Attempting to lift a car with a building hoist could result in damage to the car, the hoist, or even personal injury. For lifting a car, it's best to use a vehicle-specific lift or a hydraulic lift designed for such purposes, ensuring safety and proper support.</p>

- Q: How many floors are built to use the construction elevator? With six floors?

- The country stipulates above 7 floor to be installed elevator, of course 7 below can be installed not outfit, average 7 floor below is a ladder of ladder of ladder of ladder of ladder of ladder of ladder of ladder of ladder of stairs and so on

- Q: Describe the key differences between electric and manual building hoists.

- <p>Electric building hoists are powered by electricity and can lift heavy loads quickly and efficiently. They are automated, reducing manual labor and increasing productivity. On the other hand, manual hoists require human effort to operate, making them slower and less efficient. They are less costly but demand more physical labor, which can lead to fatigue and potential accidents. Electric hoists are suitable for large-scale construction projects, while manual hoists are often used in smaller, more confined spaces where electricity might not be readily available or where the load is not excessively heavy.</p>

- Q: This question asks about the various types of control systems used in building hoists, which are essential for the safe and efficient operation of construction elevators.

- <p>There are several types of building hoist control systems that ensure the safe and efficient operation of construction elevators. These include: 1. Manual Control Systems: Operated by a human operator who controls the hoist's movement. 2. Semi-Automatic Control Systems: Combine manual operation with some automated features, like automatic level selection. 3. Fully Automatic Control Systems: Completely automated, with the hoist moving between floors without manual intervention. 4. Microprocessor-Based Control Systems: Utilize advanced microprocessors for precise control and monitoring. 5. PLC-Based Control Systems: Use Programmable Logic Controllers for robust and customizable control. 6. Wireless Control Systems: Enable remote operation and monitoring of the hoist. Each system has its advantages and is chosen based on specific project requirements, safety standards, and budget considerations.</p>

- Q: This question asks for an explanation of the functioning of hydraulic cylinders in lifting equipment.

- <p>Hydraulic cylinders in lifting equipment operate by converting hydraulic pressure into linear mechanical motion. They consist of a cylinder barrel, a piston, and a piston rod. When pressurized fluid is introduced into the cylinder, it pushes the piston, which in turn moves the piston rod. This movement is what lifts or moves the load. The force exerted by the piston is proportional to the pressure of the fluid and the area of the piston. The cylinder's design allows for controlled and precise lifting, making it ideal for heavy-duty applications where power and control are required.</p>

- Q: What precautions should be taken when operating a building hoist to ensure safety?

- <p>Safety measures for using a building hoist include ensuring the hoist is regularly inspected and maintained, following the manufacturer's guidelines. Operators must be trained and certified. Load limits must be strictly adhered to, and the hoist should not be overloaded. A safety cage or gate should be in place to prevent accidental falls. Emergency stop switches should be easily accessible. Regular inspections for wear and tear, especially on cables and hooks, are crucial. Never use a hoist if it shows signs of damage or malfunction. Always secure loads properly to prevent them from shifting during transport.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of employing lifting equipment in the construction industry.

- <p>Advantages of using lifting equipment in construction include increased efficiency, reduced manual labor, and the ability to handle heavy loads safely. It can also improve safety by reducing the risk of injury from lifting heavy objects manually. Additionally, it allows for faster construction times and can access hard-to-reach areas. Disadvantages include high initial costs for purchasing or renting the equipment, potential for mechanical failure, and the need for skilled operators. There is also a risk of accidents if the equipment is not used properly, and it may require more maintenance and training for staff.</p>

Send your message to us

Building Hoist Hot Galvanizing Mast Section Spare Parts with 3.2ton Capacity

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords