Building Hoist Counterweight 2500k'g Lifting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist Counterweight 2500k'g Lifting

Cage is of the main running & transporting part, whose dimension and shape can be customized according to the factual site condition. Entrance & exit doors can be produced as up & down sliding or ramping model for safety and convenience. Every set of P/M hoist can be equipped with single or double cages. The entrance & exit doors and the wall of the cage can be produced with steel net, perforated steel board or aluminum plastic board. The floor and ceiling parts can be produced with steel board. On the top of the cage, there is a trap door with 0.25 m2, equipped with the limit switches. When testing and repairing, workers can climb up to the top of the cage through the ladder inside the cage. When emergency happens, the trap door can be used as exit. There are hand rails installed on the top of the cage, protecting workers from falling.

In addition, the hoist can be equipped with driving cab and rebar carrier device according to the customers’ requirements.

The mast is the force-bearing part of the hoist, also serves as the guiding rail for the cage running. Each mast section is connected with 8.8-level high strength bolts to make up the required height. The mast section, which has superior quality and significant bearing ability, is produced with quality Q235Φ76 seamless steel pipe.

The rack is the major force-bearing part mounted on the mast section, whose material has the same quality with the train wheels, after being tempered and long-time carburized, making it wear-resistant, high-ductile and long life-span.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

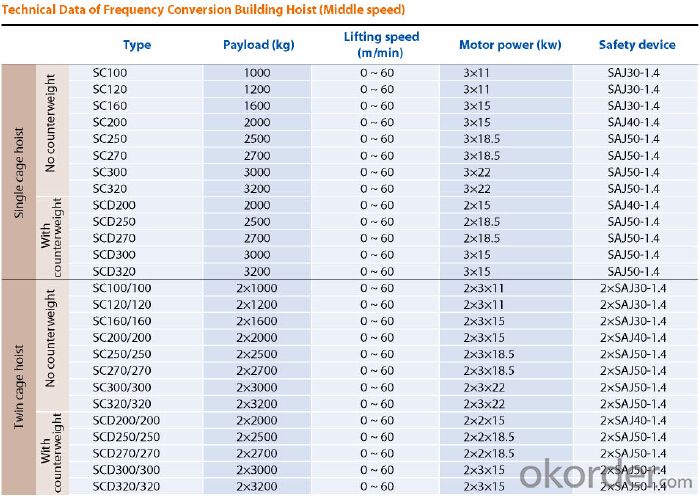

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Is it possible to use a building hoist for lifting delicate or fragile items?

- <p>A building hoist is typically designed for heavy construction materials and not recommended for lifting fragile objects. The vibrations and force exerted during lifting can damage delicate items. For fragile objects, specialized hoists or cranes with controlled movements and gentle handling capabilities are advised to ensure safety and prevent damage.</p>

- Q: Is it possible to use a building hoist for material transportation in both indoor and outdoor environments, especially in confined spaces within industrial zones?

- <p>Yes, building hoists can be used both indoors and outdoors in industrial areas, even with limited space. They are designed for material transportation during construction and are adaptable to various environments. For indoor use, hoists are often enclosed to protect from weather and debris. Outdoors, they may require additional weatherproofing. In confined spaces, compact and tower hoists are used to save space. However, safety regulations and space constraints must be considered to ensure proper installation and operation.</p>

- Q: This question asks whether a building hoist can develop operational issues due to incorrect usage or lack of maintenance.

- <p>Yes, a building hoist can malfunction due to improper use or inadequate maintenance. Improper use may include overloading the hoist, using it in unsuitable conditions, or operating it without proper training. Inadequate maintenance can lead to wear and tear, lubrication issues, and component failures. Regular inspections, proper usage guidelines, and timely repairs are crucial to prevent malfunctions and ensure the safety of the hoist and its operators.</p>

- Q: This question asks whether building hoists can be utilized in limited areas like rooms or tunnels.

- <p>Yes, building hoists can be used in confined spaces such as rooms or tunnels, but it depends on the specific design and size of the hoist. Compact and portable hoists are available for use in tight spaces. However, safety considerations, space dimensions, and the weight capacity of the hoist must be taken into account. It's crucial to ensure that the hoist is suitable for the confined area and that all safety protocols are followed to prevent accidents.</p>

- Q: This question seeks to understand the distinctions among various types of building hoists, which are essential in construction for lifting materials.

- <p>Building hoists, also known as construction hoists, are crucial for transporting materials and personnel in construction projects. The main types include: 1) Goods Hoists, designed for lifting materials and equipment, often with a higher load capacity. 2) Personnel Hoists, specifically for workers, prioritize safety features. 3) Material Hoists, a combination of goods and personnel hoists, allowing both material transport and worker movement. 4) Electric Chain Hoists, powered by electricity, known for their efficiency and control. 5) Manual Chain Hoists, requiring manual operation, useful in areas with no power supply. 6) Electric Winch Hoists, offering high lifting speeds and capacities. Each type varies in capacity, speed, control mechanisms, and power source, impacting their suitability for specific construction needs.</p>

- Q: Is it possible to utilize a building hoist for elevating materials to a significant height for stacking purposes?

- <p>Yes, a building hoist can be used for lifting materials that need to be stacked high. These hoists are specifically designed for construction sites to lift heavy materials vertically to different levels. They are equipped with safety features to ensure materials are lifted and stacked securely and efficiently. However, the height to which materials can be stacked will depend on the hoist's lifting capacity and the specific construction site's requirements. It's crucial to follow the manufacturer's guidelines and safety regulations when operating a building hoist to prevent accidents.</p>

- Q: This question asks about the various elements that can influence the efficiency and effectiveness of a building hoist.

- <p>The performance of a building hoist is affected by several factors including the type and weight of materials being lifted, the frequency of use, the hoist's mechanical condition and maintenance, environmental conditions such as wind and temperature, the skill and training of operators, and the design and capacity of the hoist itself. Proper installation, regular inspections, and adherence to safety protocols also play a crucial role in ensuring optimal performance and safety. Additionally, the quality of electrical systems, the efficiency of the drive mechanism, and the structural integrity of the hoist's components can significantly impact its operation.</p>

- Q: Is it possible to utilize a manual building hoist for the purpose of lifting heavy objects?

- <p>Yes, a manual building hoist can be used for lifting heavy objects. These hoists are designed to handle significant weights and are commonly used in construction for moving materials and equipment to various heights. They are operated manually, often with a hand crank or lever, and are equipped with safety features to prevent accidents. However, it's crucial to ensure that the hoist is rated for the weight of the objects being lifted and that all safety protocols are followed to avoid any accidents.</p>

- Q: This question asks about the safety measures that should be taken to ensure the safe operation of a building hoist during lifting.

- <p>To ensure the safety of the lifting operation of a building hoist, several key measures should be taken: Regular inspection and maintenance of the hoist equipment to ensure all components are in good working order. Adherence to the manufacturer's guidelines and safety standards for operation. Proper training for operators to ensure they understand how to use the hoist safely. Implementing a safety checklist before each use. Ensuring the load is secured properly and does not exceed the hoist's weight capacity. Using appropriate safety gear such as safety harnesses and helmets. Having a spotter or signal person to assist the operator and watch for potential hazards. Regularly checking the weather conditions to avoid operating in high winds or other adverse weather that could compromise safety.</p>

- Q: This question asks for the distinctions between two types of building hoists: manual and automatic.

- <p>Manual building hoists require human effort to operate, typically involving a pulley system and manual controls. They are generally less expensive but slower and more labor-intensive. Automatic building hoists, on the other hand, are motorized and can be programmed to lift and lower loads with minimal human intervention. They offer greater efficiency, speed, and safety, but come at a higher cost. Automatic hoists are also more suitable for high-rise construction due to their ability to handle heavier loads and operate over greater distances.</p>

Send your message to us

Building Hoist Counterweight 2500k'g Lifting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords