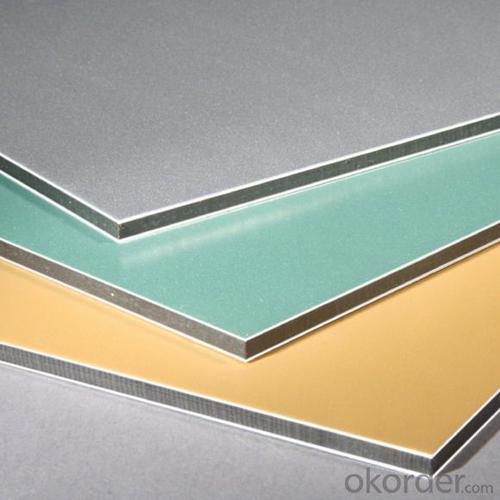

Brush Finish Aluminum Plastic Composite Panel Aluminum Compoite Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

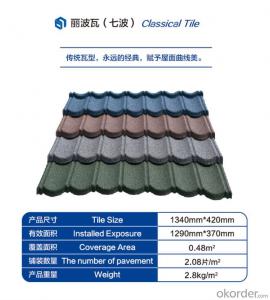

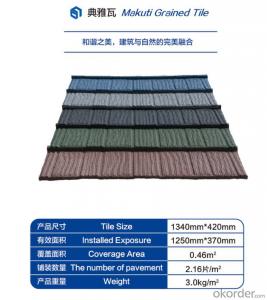

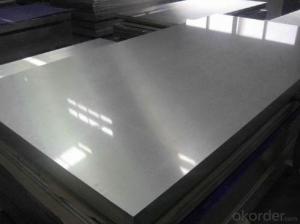

You Might Also Like

Specification

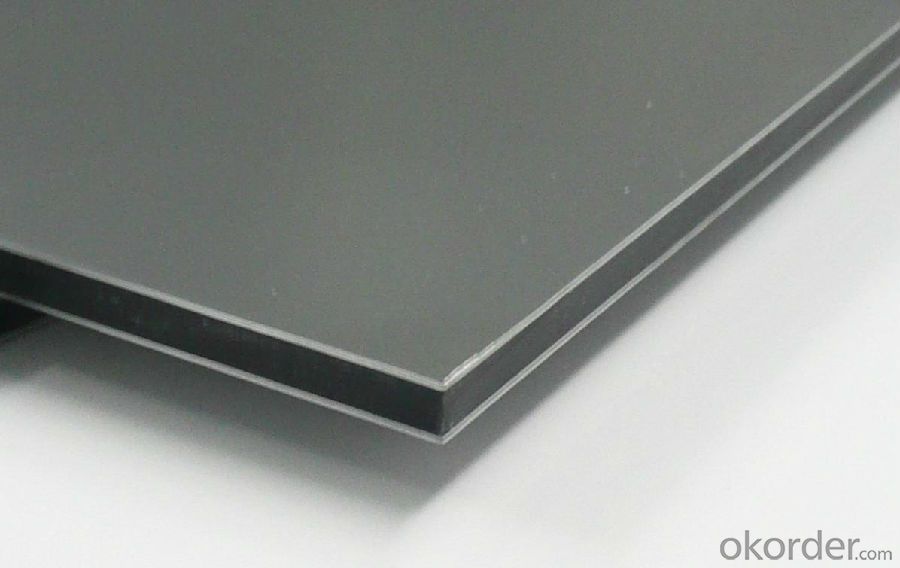

Brush Finish Aluminum Plastic Composite Panel Aluminum Compoite Sheet

| PRODUCT PARAMETER | |||||

| Product name | Pvdf Aluminum Composite Panel | ||||

| Material | Aluminum sheet and PE | ||||

| Brand name | Kaysdy | ||||

| Standard size | 1220mm x 2440mm x 3mm, 1220mm x 2440mm x 4mm | ||||

| Optional size | panel thickness | 3mm - 5.8mm | |||

| aluminum skin thickness | 0.08mm, 0.10mm, 0.12mm, 0.15mm, 0.18mm, 0.21mm, 0.25mm, 0.30mm, 0.35mm, 0.40mm, 0.45mm, 0.50mm | ||||

| panel width | 0.9m - 1.57m | ||||

| 0.9m - 1.57m | |||||

| panel Length | 5.8m is the best choice for container, or according to customized | ||||

| Core layer | Common PE or fireproof PE | ||||

| Surface coating | Polyester(PE) or Fluorocarbon(PVDF) | ||||

| Special treatment | Brushed, mirror, marble pattern, etc | ||||

| Features | 1. Excellent weather resistance | ||||

| 2. Outstanding characteristics of fireproof | |||||

| 3. High peel strength | |||||

| 4. Multiple colors | |||||

| 5. Easy and rapid installation | |||||

| 6. Environment friendly and Recycle | |||||

| 7. Perfect rigidity | |||||

| 8. Cleanness Maintenance | |||||

Pvdf Aluminum Composite Panel Material

a) Front:Aluminum-alloy sheet coated with fluoro-carbon resin (PVDF) and polyester resin (PE) roasting painting;

b) Core:nontoxic polyethylene;

c) Back:Aluminum-alloy sheet coated with polyester resin painting;

d) Surface finish:Treated with PVDF and PE resin rolling roasting coating;

e) Aluminum alloy sheet thickness: 0.04~0.5mm.

Aluminum Composite Panel Characteristics

Super peeling strength;

Excellent surface flatness and smoothness;

Superior weather, corrosion and pollutant resistance;

Even coating, various colors;

Fireproof, excellent heat and sound insulation;

Superior impact resistance;

Lightweight and easy to process;

Easy to maintain.

- Q: Aluminum plate, aluminum plate, aluminum square plate What is the difference

- Aluminum plate is made of aluminum, thick, suitable for large area, outdoor ceiling; aluminum plate with aluminum plate, are thin material, suitable for interior decoration ceiling!

- Q: Want to buy some aluminum-plastic board, what brand is better?

- There is a regional limit, if it is in Guangdong, then personally feel that the Astrid brand of aluminum-plastic plate is good Oh! And it also makes sales of glass and aluminum roll, which may be able to meet your many requirements at once.

- Q: How much is a square meter?

- Easy to operate the external wall dry aluminum plate offer 300 yuan a square, high-altitude operations, modeling complex,

- Q: What is aluminum plastic plate?

- The middle is plastic, outside the bare aluminum plate and hot pressed together the composite board.

- Q: Roof by the wood core board base, do the slope; paste the ordinary aluminum-plastic plate, leaving 0.4cm seam, sealed with structural adhesive, after a winter, structural plastic cracks, causing multiple water leakage, some time ago to make up the seal Glue, the problem is not completely resolved. Will you prawn: If you do a waterproof above, how should construction treatment?

- The basic can not be made in the aluminum-plastic roof roof waterproof layer, even if not only difficult to do more difficult to build water also poor water.

- Q: The ceiling is the singing of the aluminum plate with vibrating sound how to do it

- If invalid, it is recommended to replace the thickness of the aluminum plate

- Q: The outer wall is to play on the west is good paint, or aluminum-plastic plate is good?

- Exterior paint

- Q: Today, just started to do LED electronic light box, with aluminum-plastic plate openings, plug lights, even lights, street controller, that is done well. Ready to power, check with multimeter, find! shock! The Aluminum-plastic plate side is aluminum foil, conductive! The The 1 how to do? The The LED electronic light box, not using aluminum plate to do it? The

- With plywood, fibreboard also line (also useful iron plate, aluminum plate). But no matter what board, wires, devices, should not touch the board, should be insulated, otherwise, the rain board will be wet, but also conductive.

- Q: What is aluminum curtain wall?

- The main material used in the facade decoration is the use of aluminum-plastic plate works, focusing on a certain height of the building facade.

- Q: Can be a detailed introduction to the difference between aluminum veneer and aluminum-plastic plate, and with detailed data and unit price comparison, the scope of comparison, etc., thank you

- You can use the network to collect their own, and then use their own understanding and understanding and then sum up.

Send your message to us

Brush Finish Aluminum Plastic Composite Panel Aluminum Compoite Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords