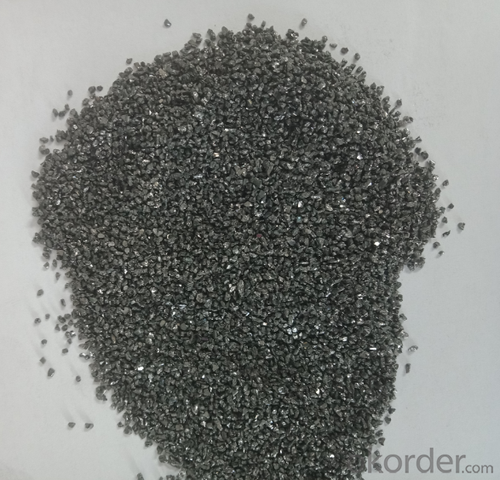

Black Silicon Carbide SIC for Metallurgy Field

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

Place of Origin: Ninxia, China

Application: Refractory, Steel making

Shape: Granule, Powder

Material: SiC, F.C

Chemical Composition: SiC, F.C

Product name: Silicon Carbide / Black Sic

Payments terms: 1. 100% L/C at sight 2. 30% T/T prepayment, balance against BL copy

Delivery Time: Within 30 days after receiving L/C or 30% T/T prepayment

Usage: Metallurgy, Foundry, Abrasive, Refractory, Deoxidizer

Advantage: Timely Shipment, High quality, Good performance

Packing: 25kg/bag, 1mt/bag or as customers' requirements

Size: 0-1/1-3/3-5mm,1-10mm, 100mesh etc

Sample supply: free sample

Color: Black

MOQ: 25Mt

Supply Ability

Supply Ability:500 Metric Ton/Metric Tons per Month

Silicon Carbide

Type | Chemical Composition | |

SiC | F.C | |

≥ | ≤ | |

SiC97 | 97 | 0.3 |

SiC95 | 95 | 0.8 |

SiC90 | 90 | 2.5 |

SiC88 | 88 | 3 |

Size: 0-1/1-3/3-5mm,1-10mm, 100mesh or as customers' requirements. | ||

Packaging & Delivery

Packaging Details1MT/bag or as customers' requirements.

PortTianjin port

Loading:

Description:

Silicon Carbide is produced by melting a mixture of silica sand and cokes in ultra high power electric furnaces. Silicon Carbide is chemically stable and has high corrosion resistance, which makes it hard to corrode from exposure to alkali or acid. Silicon carbide is also characterized by its high hardness, outstanding heat resistance, low thermal expansion, resistance to chemical reaction, and ability to function as a semiconductor.

Application:

SiC is suitable for cupola and electric furnace, widely used in iron foundries and in steel mills as deoxidizing agent, especially in ladle furnaces and electric arc furnaces during slag treatment. Silicon carbide can improve the temperature of molten steel rapidly, shorten the melting time, play the role of deoxidizing, increasing carbon and silicon, heating to improve the quality of steel.

Feature:

Black SiC, dissolved in a basic oxygen furnace used for making steel, acts as a fuel.

1.Additional energy liberated allows the furnace to process more scrap with the same charge of hot metal.

2.Silicon Carbide can also be used to raise temperatures and adjust the carbon and silicon content.

3.Silicon carbide / SiC can reduce the cost of production, produce cleaner steel and lower emissions.

Chemical Composition

- Q: A chemical problem with refractory materials

- No, in junior high school may be exposed to AlN aluminum nitride, high temperature resistant new ceramic, water will react...

- Q: How to distinguish the fire resistant level of the rubber and plastic thermal insulation material?

- Level A of non-combustible insulation materials are: W W inorganic active wall insulation materials, cement foam insulation board, glass beads of insulation mortar, rock wool board, glass wool board and foam ceramics, ect. Th e level A is non-combustible material, characterized with low density, low thermal conductivity, high bearing capacity, convenient construction, economy and durablity, and widely used as the thermal insulation materials in hot pipes, thermal equipment and other pipe-line equipment and industrial architectures, and as the thermal insulation, heat insulation and sound-absorbing materials in industrial and civil building envelope. Because of its good thermal stability, it is more used as fire-resistant protective coating material of steel structure.

- Q: What are the meanings of azs, 34% and ec in fused brick?

- The fused brick, also called zircon corundum brick, is shorted as AZS for three chemical components in Al2O3-ZrO2-SiO2 ternary diagram. I don't know the meaning of EC.

- Q: What is the criterion of entry of refractory clay industry?

- There are two requirements: (a) Enterprises mining and processing high-alumina clay meet the national industrial policy, and in line with the requirements of mineral resources planning and industrial planning, industrial development planning of high alumina clay in provinces (autonomous regions and municipalities), urban planning, the whole land use planning, mineral resources planning, environmental protection and pollution prevention planning. (b) The building of new mines of high alumina clay in areas where exploitation of mines are restricted in national and local level should be strictly limited. It is prohibited to build new mines in areas where exploitation of mines is banned, and the mines have been built should be disposed in accordance with the mineral resources planning and relevant national regulations. It is prohibited to build high-alumina clay production and processing enterprises in special conservation areas such as drinking water source reservation areas, natural reservation areas, scenic reservation areas, ecological function reservation areas, basic farmland reservation areas, cities and their suburbs, residence, schools and kindergartens, health center, hospitals and perimeter 1 km from enterprises having high requirements on the environment such as food, medicine, electronics etc., the both banks of main rivers and roads, somewhere near trunk railways.

- Q: I am a manufacturer of refractory materials. I would like to receive some orders from abroad. I would like to know what foreign trade companies in Dalian place foreign orders abroad

- You don't give a cent to this question, no one will answer it

- Q: Why do magnesium oxide refractory bricks can be made into refractories?

- The substance used in refractories must have the following characteristics and properties: 1, High stability: Anti-oxidation, anti-reduction and thermal decomposition; 2, High melting point of 2800 degree; 3, Low price. The magnesium oxide refractories have all these three characteristics and properties, particularlly in the aspects of melting point and stability .

- Q: Who knows which chrome refractories produced by the Henan refractory plant can be used for continuous casting?

- Field casting experiments are needed to verify,

- Q: Which brand of AAA refractory is good?

- Foshan Nanhai Yanbu Shuying fire-resistant insulation material is very good, and it is a professional company of the production and sale of refractories. Our company specializes in the production of refractory bricks, refractory bricks, refractory castable, refractory aggregate, refractory materials, bauxite, alumina bricks and to undertake the production of various common refractory bricks and non-sizing bricks. The Zhengzhou Fire High Temperature Materials Co., Ltd. is also a good company. It is a collection of R & D and production company. The company mainly produces refractories, refractory bricks, refractory castable, refractory aggregate, refractory materials, special refractory bricks.

- Q: How to apply the alumina powder on refractories?

- What kind of the refractories can make the aluminium oxide increase the aluminum content and specific gravity, and erosion-resistant.

- Q: What's the A class fireproof and thermal inuslation matertial for external wall?

- First, external wall thermal insulation material: 1. silicate insulation material; 2. glue powder polyphenyl granule; 3. cement cystosepiment with the use of steel wire gauze (polystyrere); 4. extruded sheet; Second, roofing materials: 1. xps extruded sheet; 2. EPS foam board; 3. perlite and perlite brick; 4. vermiculite and vermiculite brick; Third, materials for heating power and air conditioners: polyurethane, rubberplastic sponge, polyethylene, polystyrene foam, glass wool, rock wool; Fourth, steel structure material: polystyrene, extruded board, polyurethane board, glass cotton lap felt, etc.

Send your message to us

Black Silicon Carbide SIC for Metallurgy Field

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords