Black Silicon Carbide Second grade for steelmaking and foundry

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Black silicon carbide is produced at high temperature in an electric resistance type furnace with

quarts sand and petroleum coke as its main raw materials. Its hardness is between fused

alumina and synthetic diamond. Mechanical intensity of it is higher than fused alumina. It is

sharp and has electrical and heat conductivity in some degree.

Application:

1. Metallurgical deoxidizer.

2. High temperature resistant materials.

3. As abrasive, abrasive tools can be used to such as grinding wheels, whetstones, grinding head, sand tile etc.

Advantages:

1. Corrosion resistance, high strength, high hardness.

2. Good wear-resisting performance,resist to shock.

3. It is a cost-effective substitute for Ferrosilicon.

4. It has Multi-functions.

5. It costs less than ferrosilicon and carbon combination.

6. It has no dust nuisance while feeding the material.

7. It can speed up the reaction.

Specification:

(1)SIC 70%MIN, F.C 2.50%MAX, FE2O3 2.50%MAX

(2)SIC 82%MIN, F.C 2.50%MAX, FE2O3 2.50%MAX

(3)SIC 85%MIN, F.C 2.50%MAX, FE2O3 2.50%MAX

(4)SIC 88%MIN, F.C 2.50%MAX, FE2O3 2.50%MAX

SIZE: 0-1mm/1-3mm/3-8mm/3-10mm/1-10mm, 90%min

PACKING:

PACKED BASED ON BUYER'S REQUEST

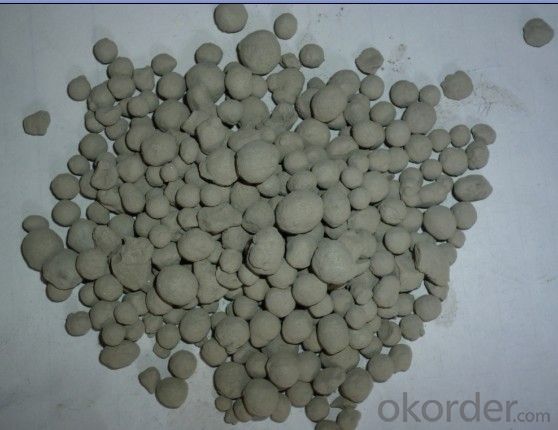

PICTURE:

- Q: Is the non-metallic mineral aggregate abrasion resistant ground constructed with concrete cushion?

- You say non-metallic mineral aggregate, wear-resistant floor should be a ground practice, and the cushion is below the surface layer, leveling, protection, not with construction. Like epoxy flooring.

Send your message to us

Black Silicon Carbide Second grade for steelmaking and foundry

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords