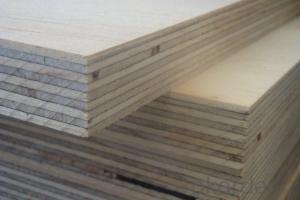

Bintangor Plywood Subfloor / Okoume Plywood Subfloor for Furniture

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Furniture Plywood/Bintangor Plywood/Okoume Plywood

Specification

1.Size:1220*2440mm, 915*1830mm, 1250*2500mm , 1830*3100mm

2.Thickness:3.6-50mm

3.Tolerance:±0.1MM to ±0.5MM

4.Material

Core:Full poplar,full pine,full hardwood,full birch,and mixed core

Face/back:Normal brown black film or dynea brown film,red film.

Glue:MR,MELAMINE E1,E2,E0,WBP

Moisture:below12%

Grade:BB/CC, BB/BB, C/D, E/F, AAA, AA, A, A/B, DBB/CC, or as your requests

Feature:Wear-resistant, anti-cracking, and alkaline-resistant

MOQ:1*40 HQ

Advantage

1) lightweight: better be used for high building and bridge construction

2) No warp, no distortin, no cleft, well water -resistant, long playing used and recycled

3) Do concrete: beautiful and slippy surface, take out the second plaster, which can save 30%

working times

4) cauterization-resistant, the concrete surface with no polluting

5) well heat preservation, in favor winter construction

6) well construction capability

7). Re-use many times: It can be used for many times if stocked correctly

8). Good thermal insulation: It is good for construction in Winter that it can be used as

template for curved surface.

9). Good construction performance: It is better than bamboo plywood and small

steel plywood in terms of nailing, sawing and drilling, It can be processed to template

with all shapes according to needs

Payment:T/T or L/C

Packing:Inner with plastic bag, outside covered with plywood or cartons, then steel tapes for strength

Applications

furniture, building boards, transport industry and under flooring

- Q: The difference between the multilayer board and the plywood is as follows

- Commonly used plywood, plywood and other multi-layer board. Multilayer boards can improve wood utilization and are a major way to save wood

- Q: The structure of the plywood at the same time meet two basic principles

- the fiber direction and the table are parallel to the long core plate or the middle plate. When forming a slab, the panel and the backplate must face outward.

- Q: Why plywood is cheaper than solid wood

- and then made of adhesive glue from the three or more layers of plate-like material, usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other

- Q: Judging wood is the standard for plywood

- If you can identify the type of wood used by your own furniture, it will help you identify the true value of the furniture

- Q: Plywood is generally used in applications where the strength and stability of the material are relatively high

- For example: Yunshan plywood is a soft Murray plywood, it can be used for housing flooring, walls and ceiling, coated surface can also be sprayed after the coating.

- Q: What types of plywood can be divided into?

- Plywood with durable, resistant to boiling or steam treatment and other properties, can be used in the outdoors.

- Q: Ordinary plywood is divided into four categories

- According to different density, divided into 80, 70, 60 three categories. Quality level for the premium, one, two three

- Q: What is the amount of construction works used for this plywood?

- Three types of plywood for moisture-resistant plywood, can be immersed in cold water for a short time, suitable for indoor use at room temperature. For furniture and general construction purposes;

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

- Q: The usual length and width specifications are:

- The main tree species are: camphor, willow, poplar, eucalyptus and so on. The main origin of plywood: Indonesia and Malaysia.

Send your message to us

Bintangor Plywood Subfloor / Okoume Plywood Subfloor for Furniture

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords