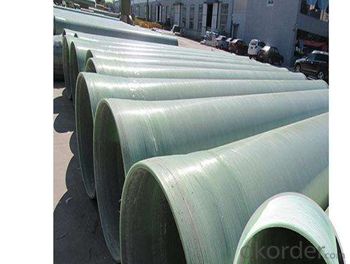

Best Quality Composite Water Pressure FRP Tanks and Vessels with No Toxic of Different Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

INSTRUCTION

FRP tanks and vessels can be largely used in many areas of the light industry, petroleum, chemical, food brewing, transportation and so on. Such product can resist the corrosion of various acids, alkalis and salts.

CHARACTERISTICS

• High mechanical strength

• High mechanical inertness

• Resistance to weathering

• Low thermal and electrical conductivity

• Long Life

• Non-toxicity

• No need for maintenance

• Light weight

Resistance to corrosion in aggressive environments is one of

the primary reasons for specifying GRP tanks. These, resists a

wide range of chemicals and temperatures and can be built to

provide additional abrasion, weathering and fire resistance. The

chemical resistance of GRP tank depends primarily on the resin/

glass matrix used. Other factors can affect laminate resistance

including liner construction, cure, and fabrication methodology

and installation techniques.

EXECUTIVE STANDARD

FRP small-scale storage tank

JC/T587-1995 (Glass fiber reinforced plastic storage tank)

Large-scale storage tank

HG/T3983-2007 Industry standards of Chemical Corrosion-resistant jobsite Winding FRP Large-scale storage tank

HG/T20696 Design Requirements of FRP Chemical Equipment

COMPANY INTRODUCTION

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products, professional service and complete solution to our customers. Strong delivery capacity, advanced technology

& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

PICTURE S

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

- Q: Is fiberglass tank good for gasoline? Would you like to use fiberglass jars to store gasoline in the ground?

- Ordinary FRP tanks are not resistant to gasoline, but are specific resins, and specific glass fibers are perfectly resistant to gasoline storage, and fiberglass tanks require special customization.

- Q: What are the technical standards for FRP tanks?

- It is usually composed of four layers: inner surface layer, inner layer, strength layer and outer surface layer. Other layered structures may also be adopted according to requirements; the wall thickness of the tank shall be based on the design requirements.

- Q: There is a storage tank, which was originally village glue, and now prepared to glue on the basis of the village glass fiber reinforced plastic anti-corrosion, can?

- Temporarily can stick glue, but toughness, thermal expansion coefficient difference between the steel and glass too much, a long time will fall off. It's best to remove the glass fiber before removing the glue.

- Q: What are the points for attention in the process of making FRP tanks?

- Just do it easy. Why do you want to do it yourself? It's bad for your health. Just pack it up when you have it. Just give you a rebate.

- Q: Should I pay attention to those details when using FRP tanks?

- One of the measures to prevent leakage is to make the double wall oil storage tank and the inner surface of the tank glass fiber reinforced plastic oil resistant impermeable layer. As a concrete method, the prepared oil storage tank is placed in the tank of underground reinforced concrete oil tank, and the glass fiber reinforced plastic oil resisting impervious layer is made on the surface of the tank. Thus, when the oil leakage occurs in the glass fiber reinforced plastic storage tank and the pipeline, the oil is not leaked in the impermeable layer of the glass fiber reinforced plastic, and the pollution of the underground water resource is avoided.

- Q: How is the head made of glass fiber reinforced plastic storage tank made?

- Process: the head is made by vacuum introduction and pneumatic demoulding process.

- Q: The thickness of the coating of glass steel tank initiations how detection

- The instrument shall be calibrated using a standard sheet of the same nature as the base metal of the component under test, and may be calibrated with the coating to be applied. Switch off during testing and restart the instrument after calibration.

- Q: Can FRP withstand 15% of sulfuric acid and nitric acid mixture?

- The glass fiber reinforced plastic or its products as materials, the title of glass fiber reinforced plastic, steel or fiberglass. Because the resin used in different varieties, so the polyester glass steel, glass steel, epoxy phenolic glass steel said.

- Q: Glass steel anti-corrosion tank glass steel coating thickness to detect initiation

- Both ultrasonic and infrared detectors are available. In fact, the atmospheric tank wall thickness is not much need to deliberately detection, as long as you can stand, do not feel very easy to deform it. Other things, such as tank wall thickness, should be noted.

- Q: Why leakage occurs during the use of FRP tanks?

- In general, there may be two possibilities, namely, bad production and nonstandard use

Send your message to us

Best Quality Composite Water Pressure FRP Tanks and Vessels with No Toxic of Different Styles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords