Best Quality Double End Tenoner

- Loading Port:

- Shunde, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pcs pc

- Supply Capability:

- 1000pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Machine Introduction Of Best Quality Double End Tenoner

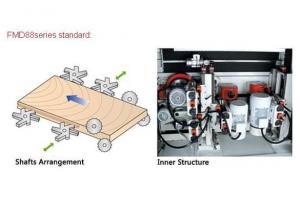

1. The machine base is processed in large CNC machine. Two high precision linear orbits are assembled to assure the stable movement and high precision.

2. Jumping device in 1st milling cutter is as the standard, can prevent tearing when grooving.

3. Adopted inverter feeding, feeding speed ups to 25m/min.

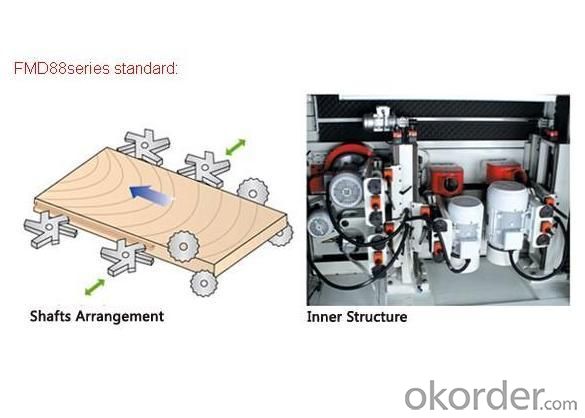

4. All the electric components are adopted international brands to assure stable and excellence performance.

5. It is suitable to process the cutting and grooving in flooring, doors, furniture etc fields.

Advantages Of Best Quality Double End Tenoner

1. Electrical movement for the pressure belt with the pneumatic locked and controlled by digital positioner.

2. Machine base is processed by big CNC machine, over 1300mm width. Two high precision linear orbits are assembled and with steel dusty proof to protect.

3. All the tools with protection cover. Under the saws, there has over 400mm width 90° dust collector, easy to clean.

4. With the special location locked system and the little fence against the work pieces just with the surface, so it will not leave pressed mark in the work pieces.

5. High speed spindle (8000r/min)

6. High precision lightweight convey belt is assembled with bearings. High feeding speed and less noise, it is suitable for high speed processing.

Specifications Of Best Quality Double End Tenoner

1. Working length(mm): 250-2500

2. Working thickness(mm): 6-80

3. OD for tools(mm)

Scoring saw: Ø 200

Cut-off saw: Ø 305

1st milling cutter: Ø 125-180

2nd milling cutter: Ø 125-180

4. ID for tools(mm)

Scoring saw: Ø 25.5

Cut-off saw: Ø 30

1st milling cutter: Ø 40

2nd milling cutter: Ø 40

5. Motor power(kw)

Scoring saw: 2.2

Cut-off saw: 5.5

1st milling cutter: 4

2nd milling cutter: 5.5

Total motor power: 35

6. Speed

Feeding speed: 5-25(m/min)

Milling cutter speed: 8000r/min

Cut-off saw speed: 3000r/min

7. Weight: 5.4T

8. Size(L*W*H)(mm): 3880*3300*1800

Packing of Best Quality Double End Tenoner

1. Manufacturer Overview

| Location | Foshan, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | Russia Federation; American Countries; European Countries; Southeast Countries |

| Company Certifications | ISO9001:2000; CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Rongqi; Beijiao; Huangpu; Shenzhen |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 301 - 500 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 15,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Best Quality Double End Tenoner

- Loading Port:

- Shunde, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pcs pc

- Supply Capability:

- 1000pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords