B Quality Fiberglass Mesh Cloth - Economic Fiber Mesh

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Details of B Quality Glass Fabric, Ecnomic Fiber Mesh

It is made from fiberglass woven roving as its basis material, then is treated by alkali-resistant macromolecule latex. It has excellent properties like high alkali resistance, flexility, tensile strength, etc. It can be widely used in wall heat reservation system, water proofness and preventing cracks.

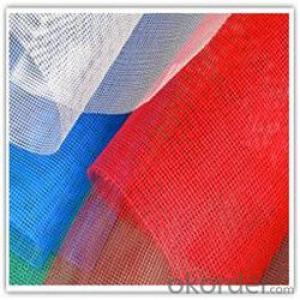

Images of B Quality Glass Fabric, Ecnomic Fiber Mesh

Specifications of B Quality Glass Fabric, Ecnomic Fiber Mesh

1. Mesh size: 5x5mm, 4x5mm or 4x4mm;

2. Weight: 160g;

3. Length/roll: 50m;

4. Width/roll: 1m;

5. Colours: White(standard), blue, green or other colors.

6. Packing: Each roll shrank wrapped, four or six rolls a carton; A 40ft container can be loaded about 80, 000- -150, 000 square meters.

7. Special items can also be done if some changes on weight, width, length, color, or packing if required by customers.

Product information of B Quality Glass Fabric, Ecnomic Fiber Mesh

Use best fiberglass yarn and best glue

High strength110g/m2, Coated Alkali-Resistent Fiberglass Mesh with High Tensile Strength

30 years experience of manufacturing B Quality Glass Fabric, Ecnomic Fiber Mesh

FAQ of B Quality Glass Fabric, Ecnomic Fiber Mesh

Q: What is Coated Fiber Mesh, 160gr/m2, A Quality Mesh?

It is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of 110g/m2, Coated Alkali-Resistent Fiberglass Mesh with High Tensile Strength?

Weight: 160g

Width: 1M

Length:50m

Q: What is the application of B Quality Glass Fabric, Ecnomic Fiber Mesh?

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement

Electrical heating mats

Marble slab reinforcement / Mosaic carrier

Asphalt reinforcement (roof water-proof)

Reinforced lightweight construction boards

Q: What is the storage of B Quality Glass Fabric, Ecnomic Fiber Mesh?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of B Quality Glass Fabric, Ecnomic Fiber Mesh?

5 r years under normal weather conditions and use .

Q: What is the package of B Quality Glass Fabric, Ecnomic Fiber Mesh?

Package: rolls are packed into cartons or pallets.

- Q: Where are the steel wire mesh and the alkali resistant grid cloth used in the exterior wall insulation?

- The wall is filled with aerated blocks. Use shotcrete interface agent and then steel wire mesh. Is the foundation for the structure of the wall, after the thermal expansion and contraction, plastering no hollowing, cracking. Using mesh cloth for full paving. To reach the wall roughness, strengthen the surface cohesion, and consolidate the grassroots. Steel nets are generally used in the decoration, in the masonry wall and the original wall of the junction, but also can be used in the light body wall reinforcement. Mesh cloth is suitable for use in many parts.

- Q: What kind of wall fabric is covered with fiberglass mesh? Do you apply the powder or the powder? Thank you

- The interior powder is usually used at the joint of the wall (there is a mesh fabric specially used for joint, called adhesive tape or joint tape)

- Q: How to fill the sample size of glass fiber mesh cloth, fill what general specifications

- Therefore, the utility model has the advantages of good alkali resistance, flexibility, and high tensile resistance at warp and weft direction. The utility model can be widely used for heat preservation, water resistance and crack resistance of walls inside and outside buildings. Glass fiber mesh cloth with alkali resistant fiberglass mesh, it uses alkali free glass fiber yarn (the main ingredient is silicate, good chemical stability) by structure leno weaving and special organization, after the anti alkali, heat setting treatment such as reinforcing agent.

- Q: What is the function of the wall cloth mesh?

- The main uses are widely used:1) wall reinforcement materials (such as glass fiber wall, net cloth, GRC wallboard, EPS internal and external wall insulation board, gypsum board and so on.2) reinforce cement products (such as Rome column, flue, etc.).3) granite, mosaics, special mesh, marble back net.4) waterproof coiled material and bituminous roof waterproof.5) strengthen the skeleton material of plastic and rubber products.

- Q: Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- It would be to see how the strength of cement foam insulation board, and you paste the process in order to improve the strength, you can use 1 to 1 fiber cement mortar with latex mixing, can increase the thickness and strength, the cost will be reduced, it can in the brick veneer.

- Q: What harm does fiberglass mesh have to people?

- Into the digestive system, may cause digestive diseases.

- Q: What is the difference between alkali resistant fiberglass mesh and glass fiber mesh fabric?

- Alkali resistant glass fiber mesh cloth on the alkali or alkali glass fiber woven fabrics based coating formed by the alkali, the product of high strength, good bonding, docile, excellent positioning, widely used in the reinforcement of walls, wall insulation, roofing and other aspects

- Q: Slotted walls, seams, seams, tape, or anti mesh cloth?

- Because in the fiber wall sealed with aging, so. Then through the plaster smooth dry, tore the cloth into strips, glue brush in the gap, and then dried, powder, and will not crack, affordable, the effect is very good.

- Q: What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- How to identify quality problems of alkali resistant glass fiber cloth, glass fiber cloth market price of 1. of the worst is usually around 1 yuan -1.60 yuan, his glass fiber is usually made of some kind of waste glass beer bottles, the production process for clay crucible drawing, production process is prohibited by the state, the surface coating is non alkali resistant emulsion. From the intuitive point of view: the work is relatively rough, generally sold in the market volume of the theory, often lack of length, grams of weight is not enough, two fold on the break, the contact is not firm, easy to shift, and easy to stab the skin. In the insulation layer in general in the two months after the loss of strength using the grid cloth, if the mortar off grid cloth out, just gently crushed, fiberglass yarn is made into powder.

- Q: What is the quota of alkali resistant fiberglass mesh cloth sleeve?

- 5 thick wall plastering mortar is pressed into the middle layer of alkali resistant glass fiber mesh, 03 quota is not suitable to apply the quota items, should set their own preparation of the quota items.

Send your message to us

B Quality Fiberglass Mesh Cloth - Economic Fiber Mesh

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords