Automatic Deduction Cans Molding Machine for Can Makers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

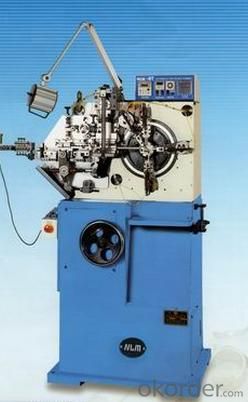

Automatic Deduction Cans Molding Machine for Can Makers

1. Product Description:

The deduction manually punching machine has good quality, easy operation and favorable price. It could be used for sealing the T-shirt bag, sausage, ham and so on. cans.

2. Product Features:

Automatic eyelet machine

High quality, easy operation

Fast speed, auto

Central lubrication system

Easy adjustment, no need touch screen single action

3. Product Parameters:

Model | DK |

Capacity fasteners | 220V/380V 50Hz |

Buckle model | U 506 |

Dimension | 4200×1600×7700mm |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

5. Product Pictures:

- Q: How are the birthday cakes wrapped? How do cake boxes shape?

- Wrap it in a plastic bag and place it in an ordinary fabric bag

- Q: Our company is a PCB drilling machine and forming machine, and recently there are several customer inquiries about which machines and PCB PCB manufacturing processes are needed to open the plant

- Screen printing text: through web printing or ink to form text, easy to welding identification;Surface treatment: tin spraying, gold deposition, OSP, gilding and so onElectrical test: test whether the PCB has an open short circuitMolding: numerical control, stamping formingPacking: vacuum packing, avoid scratch and oxidation!

- Q: How much is the gas consumption per EPS molding machine per hour?

- 1000 automatic quantitative preforming machine, designed for packaging design, pre density accurate, convenient operation, uniform bead.

- Q: RT... What are the forming methods of plastic forming dies? Which expert answers, thank you very much...

- 1, plastic injection mold: it is thermoplastic plastic products the most universal of a mold used in the production and processing equipment for plastic injection molding is the corresponding processing equipment for plastic injection mold is the corresponding plastic injection molding machine, plastic injection machine in the first floor heating cylinder heated melting, and then in the injection machine screw or plunger driven by the gating system of injection machine and mold nozzle into the mold cavity plastic molding cooling sclerosis strippingget products. The structure is usually composed of molding parts, gating system, guiding parts, pushing out mechanism, temperature regulating system, exhaust system and supporting parts. The material is usually made of plastic mould steel, and the common materials are carbon structural steel, carbon tool steel, alloy tool steel, high speed steel and so on. Injection molding processing usually apply only to thermal plastic products production, with production of injection molding of plastic products is very wide, from the daily necessities of life to all kinds of complicated machinery, electrical appliances, transport and other parts are used injection molding die, it is a kind of processing method is most widely used in the production of plastic products.

- Q: Blow molding process conditions The purpose of the adjustment of technological conditions is that,

- Use the established computer model to simulate the status of blow molding die, blanking billet and clamp plate;Enter the parameters affecting the wall thickness distribution of parison at each stage;The simulation results are analyzed, and computer simulation shows that the wall thickness is not enough, and which parts are super thick;

- Q: What are the sensory standards in the hygienic standard for polyethylene used in food packaging?

- Method for analysis of hygienic standard for polyethylene, polystyrene and polypropylene moulding products for food packagingGB/T 5009.101Determination of antimony in polyester resins and their moulding products for food containers and packaging materialsGB 9685Hygienic standard for the use of additives for food containers and packaging materialsGB/T 12025High density polyethylene blown filmGB 13113Food containerHygienic standard for polyethylene terephthalate molded articles and packaging materials

- Q: What are the factors affecting the packaging quality of bag molding, filling, sealing and packaging?

- What are the factors affecting the packaging quality of bag molding, filling, sealing and packaging?First, material impactThe general composite film type food packaging bag has a certain heat sealing performance, mainly after the product is loaded into the customized food packaging bag and can be sealed through a sealing machine.

- Q: What kind of equipment do you need for washing powder packaging bags, a production line, starting from the membrane, what kind of blowing machine, etc., and finally formed into washing powder packaging bags

- Laundry bags generally use nylon or PET as the outermost layer,

- Q: Would you like to ask what is the difference between a cold stamping foil and a plain foil wrapper?

- Medical aluminium foil paper - features1., good mechanical properties, can meet the use of automatic packaging machinery requirements, but the lack of flexibility. Tear strength is low, easy to break at the fold. Easy to process, it can be combined with plastic film, paper and other packaging materials, and easy to coloring and printing2. light weight, is conducive to reducing transportation costs

- Q: What's the use of a laser word light for cutting machines?

- It can play a role, such as auxiliary marking and location: material cutting, woodworking machinery, packaging machinery, stone bridge cutting machine, tire positioning and positioning in the fabrication of glass fabric processing, welding processing, PCB processing; sheet metal processing machinery manufacturing, steel line positioning; garment material cutting

Send your message to us

Automatic Deduction Cans Molding Machine for Can Makers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches