Automatic Climbing Formwork In Construction Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Climbing Formwork In Construction Building

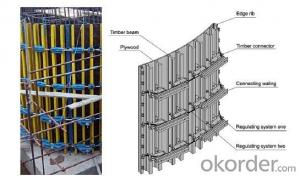

The Formwork Center of CNBM dedicates tothe design, manufacture and supply of formwork and scaffolding in fields ofCivil Engineering, Bridge-Road Projects,Tunnel andDams.

TheFormwork Center of CNBM is managed by highly technical professionals having indepth knowledge, competence to design, develop and manufacture excellentquality products.

The workshop covers an area 8000M2, and in the plant there are automatic finger jointing machine, rack shaping and mortising machine, multi-blade saw, multi-spindle moulder, glue spreader and other advanced equipment. The production capacity of timer beams is 3000M/day.

Packing

in bulk or in bundle, or as requested

Shipping

25-30 Days.

Normally small orders, it needs just 15-20 business days to the port. For goods with stock, it would be even shoter.

We can ensure the quality of the Timber Beam Wall Formwork and avoid extra expenses for customers.

We can provide you the professional technical team.

We can provide professional building proposal for your projects.

Automatic Climbing Formwork In Construction Building

CNBM Formwork Products Series

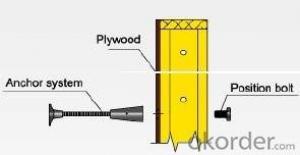

Formworksystem:

Timber-beamformwork:

1,TableFormwork:

2,Walland Column Formwork:

3,Auto-climbing Formwork:

4,Auto-climbing ProtectionPanel:

Steel-frameformwork:

Wall and Column Formwork:

Aluminum-frameformwork:

Slab Formwork

Wholealuminum formwork

Slab,Wall,Column and Beam Formwork

Wholesteel formwork

Wall,Column Formwork,and BrigdeFormwork

Scaffoldingsystem

Steelprop & Beam clamp

Ring-lockscaffolding,Cup-Lock scaffolding,

Tower scaffolding

Automatic Climbing Formwork In Construction Building

Automatic Climbing Formwork In Construction Building

FAQ Automatic Climbing Formwork In Construction Building

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

We can ensure the quality of the Timber Beam Wall Formwork and avoid extra expenses for customers.

We can provide you the professional technical team.

We can provide professional building proposal for your projects.

- Q: What is the use of building wall formwork support? Thank you

- To build a scaffold to form a bracket supported by steel or wood, and with steel formwork concrete construction.

- Q: Technical specification for construction formwork safety JGJ162-2008 who has made me please

- This specification is applicable to the design, manufacture, installation and dismantling of the cast-in-place concrete engineering formwork system in construction.

- Q: 1, JGJ162-2008 construction formwork safety technical specification;2, JGJ130-2011 construction fastener type steel pipe scaffolding safety technical specifications; the friend has. Send me thanks

- 3 2.1.12 flying die flying shuttering mainly by the platform board, support system (including beam, support, support, legs, etc.) and other accessories (such as lifting and walking mechanism, etc.). The utility model is a large tool type template, which is called a table mould or a table model because of the appearance of the utility model. Because it can take advantage of lifting machinery, pouring from the well under the floor of the lift out of the transfer to the upper layer of repeated use, so called flying mode. 2.1.13 tunnel mode tunnel shuttering a combination of stereotypes template, while pouring concrete wall and floor of the template, because the shape of the template like a tunnel, it is known as the tunnel model.

- Q: 86335 template support, what is the concept of those advantages

- Product features:Features: keel tight flexible connection not only makes the operation simple and easy, and the structure is stable.Features two: retractable keel allows you to adapt to any size.Features three: the column and the keel of the clever self-locking connection is not only simple and stronger.Features four: tie rod light not only save material, and is more flexible and firm, flexible fastener is a mustFeatures five: compared to the wooden beam structure is more accurate, more secure.Features six: the construction site is beautiful and clean, greatly enhance the corporate image, highlighting the strength of enterprises.Features seven:: labor, material saving, time saving, more security.Features eight: do not use wood, energy saving and environmental protection, the product can be reused, so that the construction cost is greatly reduced.Improve efficiency: construction without any technology, will be, efficiency increased by 600%.Do not use: do not use a round nail, wire, wood, without any tools to reduce the cost of a large number of countries can save a lot of wood.High safety: complete steel structure, standard fasteners, tight structure, compact connection, safe and reliable.Beautiful and neat: construction site clean and orderly, easier to manage, improve the image of the project. High precision and stability.

- Q: Since the building, and I would like to ask some of the basic knowledge to the construction of a unified drawing, plus or minus 0 and the height of the drawings, the roof slope requirements. Now the blue steel reinforced concrete inclined roof beams or do. Here we use multiple beams, and the waterproof, thermal insulation, in tile. Anyway, many shortcomings is wood, attic space basically scrapped, there is a fire started...I would also like to use concrete flat top, that is, do not let, more depressed.If I can use wooden beams, waterproof SBS, hanging plastic extruded board?The construction of plastic extruded board in inclined roof beams hung strong? Construction is not difficult?As well as the 8X11 meters of the roof, 30 degrees slope, sloping roof concrete cost about? I feel modeling and cloth reinforcement are very troublesome, expensive cost estimation

- You can put the beam properly after the play flowers on top, which is the slope of the wall, so that you can

- Q: What is the building template support

- In the construction for concrete cast-in-place construction formwork supporting structure, widely used in steel or timber beams assembled into the template bracket, built into the scaffold to form a bracket supported by steel or wood, and with steel formwork concrete construction.

Send your message to us

Automatic Climbing Formwork In Construction Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches