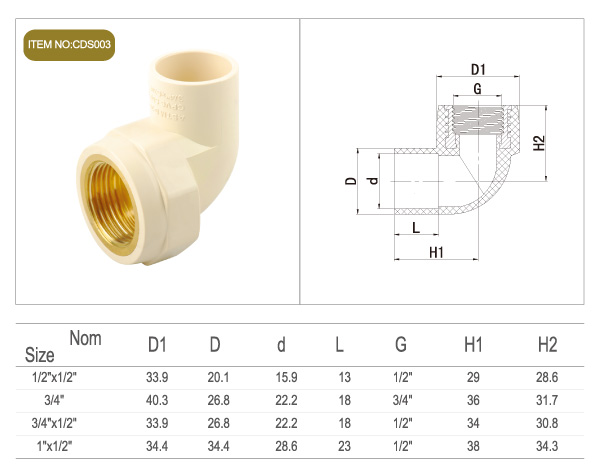

ASTM D2846 CPVC Brass Threaded Female Elbow 3/4 Plastic Water Pipe Fittings

- Loading Port:

- Nanjing

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Quick Details | |

| Material: Plastic | |

| Technics: injection | Connection: Female |

| Type: elbow | Shape: Other |

| Place of Origin: China (Mainland) | Head Code: round |

| Model Number: CDS003 | Color: beige |

| Certification: NSF, ASTM D2846 | Size: 1/2"~2" |

| Packaging & Delivery | |

| Packaging Details: | 51.5*40*550px; 49*39*950px; 39*25.5*625px |

| PE poly bag+ carton | |

| 385-1130 CTNS/ 20 CONTAINER; 935-2740 CTNS/ 40HQ | |

| Delivery Detail: | 15 days. |

Specifications

Material:CPVC

Standard: ASTM D-2846

Pressure:PN25(2.5Mpa)

Size:1/2"-2"; Color: beige

Certificate: ISO9001, ISO14001,NSF

CPVC MALE ADAPTOR

1. Material: CPVC

2. Size: 1/2"to2"

3. Standard: ASTM D-2846

4. Certification: ISO9001 ISO14001,NSF

5. Best price,excellent quality,quick delivery

Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Light weight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Extremely long usage life for at least 50 years

- Q: Can plastic pipe fittings be used for agricultural irrigation systems?

- Yes, plastic pipe fittings can be used for agricultural irrigation systems. Plastic fittings are commonly used in these systems due to their durability, corrosion resistance, and ease of installation. They are also cost-effective and can withstand the harsh conditions associated with agricultural irrigation, such as exposure to chemicals and varying weather conditions.

- Q: Can plastic pipe fittings be used in mining applications?

- Yes, plastic pipe fittings can be used in mining applications. They are often preferred due to their corrosion resistance, lightweight nature, and ease of installation. Plastic fittings can effectively handle the demands of mining operations while also offering cost and maintenance benefits.

- Q: Can plastic pipe fittings be used in fireproof systems?

- No, plastic pipe fittings cannot be used in fireproof systems as they have a low melting point and are not resistant to high temperatures.

- Q: Are plastic pipe fittings suitable for use in swimming pools?

- Yes, plastic pipe fittings are suitable for use in swimming pools. They are commonly used due to their durability, corrosion-resistance, and affordability.

- Q: Can plastic pipe fittings be used for radiant heating systems?

- Yes, plastic pipe fittings can be used for radiant heating systems. Plastic fittings, such as PEX (cross-linked polyethylene) fittings, are commonly used in radiant heating installations due to their durability, flexibility, and resistance to corrosion. They can effectively connect and distribute hot water throughout the radiant heating system, providing efficient and reliable heat transfer.

- Q: Can plastic pipe fittings be used in marine applications?

- Yes, plastic pipe fittings can be used in marine applications. They are often preferred due to their corrosion resistance, durability, and lightweight properties. However, it is important to select fittings specifically designed and rated for marine use to ensure they can withstand the unique challenges posed by saltwater, UV exposure, and other harsh marine conditions.

- Q: What are the common operating temperatures for plastic pipe fittings?

- The common operating temperatures for plastic pipe fittings typically range from -40°C to 60°C (-40°F to 140°F).

- Q: Are plastic pipe fittings suitable for rainwater harvesting systems?

- Yes, plastic pipe fittings are suitable for rainwater harvesting systems. They are commonly used due to their durability, affordability, and resistance to corrosion. Additionally, plastic fittings are easy to install and maintain, making them a practical choice for collecting and distributing rainwater.

- Q: Can plastic pipe fittings be used for chemical storage facilities?

- No, plastic pipe fittings are generally not suitable for chemical storage facilities as they may not have the required chemical resistance and could lead to leaks or contamination. It is recommended to use corrosion-resistant materials such as stainless steel or specialized chemical-resistant plastics for these applications.

- Q: Can plastic pipe fittings be used for chemical dosing in water treatment?

- Yes, plastic pipe fittings can be used for chemical dosing in water treatment. Plastic fittings are commonly made from materials like PVC, CPVC, or polypropylene, which are resistant to many chemicals and can withstand the corrosive nature of certain water treatment chemicals. Plastic fittings also offer cost-effectiveness, durability, and easy installation, making them suitable for various applications in water treatment processes. However, it is important to consider the specific chemicals being used and ensure that the chosen plastic fittings are compatible with those chemicals to avoid any potential reactions or leaching.

Send your message to us

ASTM D2846 CPVC Brass Threaded Female Elbow 3/4 Plastic Water Pipe Fittings

- Loading Port:

- Nanjing

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords