ASTM D2846 CPVC Pipes and Plastic Water Pipe Fittings

- Loading Port:

- Nanjing

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Quick Details | |

| Material: Plastic | |

| Technics: injection | Connection: Glue |

| Type: Pipe | Shape: Equal |

| Place of Origin: China (Mainland) | Head Code: round |

| Model Number: CP001 | Color: beige |

| Certification: NSF, ASTM D2846 | Size: 1/2"~2" |

| Packaging & Delivery | |

| Packaging Details: | PE poly bag+ carton |

10 days. | |

| Delivery Detail: |

Specifications

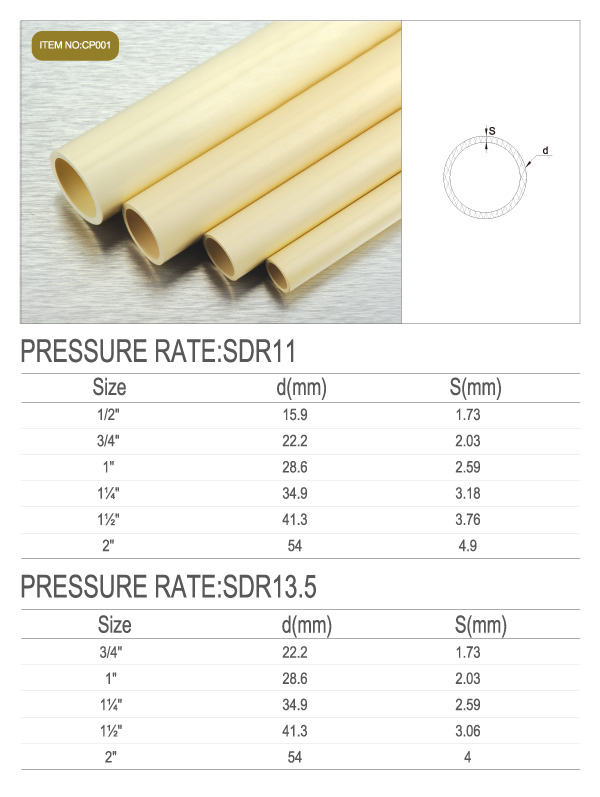

Material: CPVC

Standard: ASTM D-2846

Pressure: PN25(2.5Mpa)

Size: 1/2"-2"; Color: beige

Certificate: ISO9001, ISO14001,NSF

CPVC MALE ADAPTOR

1. Material: CPVC

2. Size: 1/2"to2"

3. Standard: ASTM D-2846

4. Certification: ISO9001 ISO14001,NSF

5. Best price,excellent quality,quick delivery

Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Light weight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Extremely long usage life for at least 50 years

- Q: Can plastic pipe fittings be used for solar thermal systems?

- Yes, plastic pipe fittings can be used for solar thermal systems. Plastic pipe fittings, such as those made from PVC or CPVC, are commonly used in solar thermal systems due to their resistance to corrosion and high temperatures. These fittings are lightweight, easy to install, and cost-effective, making them a popular choice for connecting and routing pipes in solar thermal applications.

- Q: Are plastic pipe fittings resistant to UV radiation?

- Yes, plastic pipe fittings can be resistant to UV radiation. Many modern plastic pipe fittings are specifically designed and manufactured with UV stabilizers, which help to protect them from the damaging effects of UV radiation. These stabilizers prevent the plastic from degrading, becoming brittle, or losing its structural integrity when exposed to sunlight and other sources of UV radiation. However, it is important to note that not all plastic pipe fittings are UV resistant, so it is crucial to choose fittings that are specifically labeled or specified to have this property if UV exposure is a concern.

- Q: Can plastic pipe fittings be used for irrigation filtration systems?

- Yes, plastic pipe fittings can be used for irrigation filtration systems. Plastic pipe fittings are commonly used in irrigation systems due to their durability, corrosion resistance, and affordability. They can easily be connected to various types of pipes and are compatible with different filtration components, making them suitable for the construction of irrigation filtration systems.

- Q: Can plastic pipe fittings be used in areas with high water pressure?

- Yes, plastic pipe fittings can be used in areas with high water pressure. However, it is crucial to ensure that the plastic fittings are specifically designed and rated for high-pressure applications. Using fittings that are not suitable for high water pressure can result in leaks, bursts, and other plumbing issues. It is advisable to consult with a professional plumber or refer to the manufacturer's guidelines to determine the suitability of plastic pipe fittings for a particular high-pressure area.

- Q: Can plastic pipe fittings be used for stormwater management?

- Yes, plastic pipe fittings can be used for stormwater management. Plastic pipe fittings are commonly used in stormwater management systems due to their durability, resistance to corrosion, and ease of installation. They are also cost-effective and can effectively handle the flow of stormwater in various applications such as drainage systems, culverts, and retention ponds.

- Q: How do plastic pipe fittings handle seismic activity?

- Plastic pipe fittings are designed to withstand seismic activity by being flexible and resistant to vibrations. The material used in plastic fittings, such as PVC or HDPE, allows them to absorb shocks and movements caused by earthquakes. These fittings can flex and bend without breaking, reducing the risk of pipe damage or leakage during seismic events. Additionally, plastic fittings are lightweight and easy to install, making them a popular choice in earthquake-prone areas.

- Q: Are plastic pipe fittings resistant to ultraviolet degradation?

- Yes, plastic pipe fittings can be resistant to ultraviolet degradation. Many plastic materials used in pipe fittings, such as PVC (polyvinyl chloride) and CPVC (chlorinated polyvinyl chloride), are formulated to have UV stabilizers that protect against the harmful effects of ultraviolet radiation, making them suitable for outdoor applications. However, the degree of UV resistance can vary depending on the specific material and its formulation, so it is important to choose fittings specifically designed for UV exposure if required.

- Q: Can plastic pipe fittings be used in underground applications?

- Yes, plastic pipe fittings can be used in underground applications. They are commonly used in underground plumbing systems, drainage systems, and irrigation systems due to their durability, corrosion resistance, and ease of installation. Plastic pipe fittings are designed to withstand the environmental conditions present underground and can provide long-lasting and reliable performance.

- Q: Can plastic pipe fittings be used in conjunction with metal pipe fittings?

- Yes, plastic pipe fittings can be used in conjunction with metal pipe fittings.

- Q: Are plastic pipe fittings compatible with push-to-connect fittings?

- Yes, plastic pipe fittings are generally compatible with push-to-connect fittings. These fittings are designed to work with various types of pipes, including plastic pipes, ensuring a secure and leak-free connection. It is important to check the specific compatibility of the fittings and pipes being used to ensure a proper fit.

Send your message to us

ASTM D2846 CPVC Pipes and Plastic Water Pipe Fittings

- Loading Port:

- Nanjing

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords