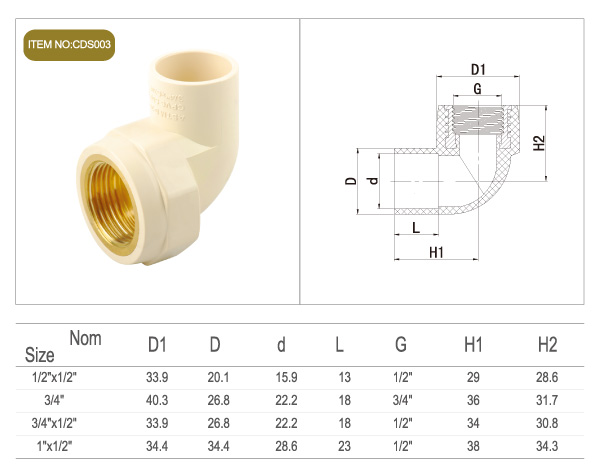

ASTM D2846 CPVC Brass Threaded Female Elbow 3/4 Plastic Water Pipe Fittings

- Loading Port:

- Nanjing

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Quick Details | |

| Material: Plastic | |

| Technics: injection | Connection: Female |

| Type: elbow | Shape: Other |

| Place of Origin: China (Mainland) | Head Code: round |

| Model Number: CDS003 | Color: beige |

| Certification: NSF, ASTM D2846 | Size: 1/2"~2" |

| Packaging & Delivery | |

| Packaging Details: | 51.5*40*550px; 49*39*950px; 39*25.5*625px |

| PE poly bag+ carton | |

| 385-1130 CTNS/ 20 CONTAINER; 935-2740 CTNS/ 40HQ | |

| Delivery Detail: | 15 days. |

Specifications

Material:CPVC

Standard: ASTM D-2846

Pressure:PN25(2.5Mpa)

Size:1/2"-2"; Color: beige

Certificate: ISO9001, ISO14001,NSF

CPVC MALE ADAPTOR

1. Material: CPVC

2. Size: 1/2"to2"

3. Standard: ASTM D-2846

4. Certification: ISO9001 ISO14001,NSF

5. Best price,excellent quality,quick delivery

Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Light weight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Extremely long usage life for at least 50 years

- Q: Can plastic pipe fittings be used for geosynthetic clay liner systems?

- No, plastic pipe fittings cannot be used for geosynthetic clay liner systems. Geosynthetic clay liners require specialized fittings designed specifically for their installation to ensure proper functionality and performance.

- Q: Spiral drain pipe fittings are not special pipe fittings

- Because the product of the tube holes in the trough, and elongated, effectively overcomes the planar circular hole is easy to block defects affect product drainage effect, according to the requirements of different drainage tube hole size is 10mm * 1MM-30MM * 3mm, and at 360 degrees, 270 degrees, 180 degrees, 90 degrees. Within the scope of the uniform distribution, widely used in highway, railway subgrade, subway engineering, waste landfill, tunnel, greening slope protection drainage belt, athletic field and high water content caused by agriculture, gardening, and underground irrigation and drainage system. It has become the three main products of civil engineering construction (water seepage, drainage) with soft permeable pipe and plastic blind ditch. According to the drainage pressure of municipal drainage network, double arm bellows and straight wall pipe can be used. The pressure of the straight wall pipe is stronger, and it can be used in the special pipe of large-scale drainage and sewage pipe network.

- Q: Can plastic pipe fittings be used for oil refinery processes?

- No, plastic pipe fittings are not suitable for oil refinery processes due to their inability to withstand high temperatures and the corrosive nature of the chemicals involved.

- Q: How to calculate joint parts for hot melt connection of water supply plastic pipe?

- The hot melt connection directly connects the pipe and does not need the fittings

- Q: How do you remove plastic pipe fittings?

- To remove plastic pipe fittings, you can follow these steps: 1. First, turn off the water supply to the pipe you are working on. This will prevent any leaks or water damage during the removal process. 2. Use a pair of pliers or a wrench to loosen the fitting. Grip the fitting firmly and rotate it counterclockwise to loosen it. If the fitting is stuck or too tight, you can use a pipe wrench or adjustable spanner for more leverage. 3. Once the fitting is sufficiently loosened, you can try pulling it straight off the pipe. If it doesn't come off easily, you can use a pipe cutter or hacksaw to carefully cut the plastic pipe just above the fitting. This will allow you to remove the fitting without damaging the rest of the pipe. 4. After removing the fitting, inspect the pipe for any damage or debris. Clean the pipe and fitting ends thoroughly before installing a new fitting. Remember to take necessary precautions, such as wearing gloves and eye protection, as you work with tools and potentially sharp edges.

- Q: Can plastic pipe fittings be used for natural gas systems?

- No, plastic pipe fittings are not suitable for natural gas systems. Natural gas is highly flammable and requires materials that can handle the high pressure and extreme temperatures associated with its use. Therefore, metal pipe fittings, such as those made from steel or brass, are the recommended choice for natural gas systems.

- Q: Can plastic pipe fittings be used for water treatment plants?

- Yes, plastic pipe fittings can be used for water treatment plants. Plastic pipe fittings are commonly used in water treatment plants due to their durability, corrosion resistance, and ease of installation. They are often made from materials such as PVC, CPVC, or HDPE, which are approved for use in water treatment applications. Plastic fittings are suitable for various processes within water treatment plants, including conveying water, chemicals, and wastewater. Additionally, plastic fittings are cost-effective and have a long service life, making them a practical choice for water treatment plants.

- Q: Can plastic pipe fittings be used for outdoor applications?

- Yes, plastic pipe fittings can be used for outdoor applications. However, it is important to ensure that the fittings are made of a durable and weather-resistant material, such as PVC or CPVC, to withstand the elements and prevent damage or deterioration over time. Additionally, proper installation and maintenance are essential to ensure the longevity and functionality of the fittings in outdoor settings.

- Q: Are plastic pipe fittings resistant to fungal growth?

- Yes, plastic pipe fittings are generally resistant to fungal growth due to their non-porous nature, which makes it difficult for fungi to thrive and grow on the surface. Additionally, most plastic pipe fittings are manufactured with antimicrobial properties that further inhibit the growth of fungi and other microorganisms.

- Q: PE copper wire mesh plastic composite pipe connection in several ways?

- E copper wire mesh skeleton plastic composite pipe is connected by electric heating welding method and flange connection two ways. Electric melting connection is inserted into the electric melting pipe composite pipe, the electric heat wire is embedded on the surface of the heat pipe fitting.

Send your message to us

ASTM D2846 CPVC Brass Threaded Female Elbow 3/4 Plastic Water Pipe Fittings

- Loading Port:

- Nanjing

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords