Artificial Graphite(MCMB) For Lithium Ion Battery

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 120000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

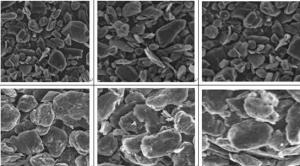

We can provide a series of vibration molding specialty graphite from coarse to medium grain, available mainly as round and rectangular blocks with the grain size from 0.8 to 4mm. Simple-shape machined parts, such as graphite plates, bricks, discs and sleeves can also be provided. Highly homogenous structure, excellent consistence, and outstanding performance set our 0.8mm-grain graphite apart from other competitors in China and make them parallel with any world top grade in their line.

Application:

They are mainly used in cement industries in kiln machines. These industrial graphite blocks are also used in various chemical industries like copper, zinc, aluminum extrusions industries, glass, cables manufacturing units, paper mills etc. We make our graphite carbon blocks available in the best quality and that also at the industry leading prices.

Specification:

|

Test Item |

Unit |

1 |

2 |

3 |

|

Electric Resistance |

µΩm |

8.3 |

≤8.0 |

≤9.0 |

|

Bulk Density |

g/cm3 |

1.72-1.74 |

1.70-1.72 |

1.68-1.70 |

|

Grain Size |

mm |

0.8 |

0.8 |

0.8 |

|

Compressive Strength |

Mpa |

40 |

≥35 |

≥32 |

|

Bending strength |

Mpa |

17.5 |

≥14.5 |

≥14.5 |

|

Porosity |

% |

18 |

≤20 |

≤22 |

|

Ash Content |

% |

0.09 |

≤0.2 |

≤0.3 |

|

C.T.E. |

100-6/°c |

2.4 |

2.5 |

2.9 |

|

Size |

mm |

400x400x1800-2600 650x400x1800-2600 760x500x1830-2000 950x500x1900 |

500x500x1800-2600 610x610x1800-2600 850x400x1800-2600 1120x400x2200 | |

- Q: Is it better to use formaldehyde in addition to formaldehyde?

- As far as I know the activated carbon in addition to formaldehyde will be secondary pollution, adsorption saturation after a rise in temperature will be re-released, you can use Egyptian carbon crystal can be adsorbed or can be decomposed material or processed by the adsorption more Strong activated carbon type in addition to formaldehyde. I hope I can help you.

- Q: Used activated carbon and have not used the difference between it

- There are differences, used with pollutants, no use is not.

- Q: Activated charcoal is a simple substance or a compound

- Activated carbon is simple. Is a way of existence of carbon.

- Q: Is activated carbon a hazardous chemical? Are waste activated carbon hazardous to waste?

- Activated carbon is a chemical. Chemicals are pure ingredients and mixtures of various elements, whether natural or artificial. However, activated carbon does not belong to hazardous waste.

- Q: What are the advantages of graphene powder compared to activated carbon?

- Gypsum has a large specific surface area and strong adsorption properties, which can be combined with conventional photocatalyst products to improve its performance. For example, the sensitivity to UV conditions is reduced and the common light can stimulate the reaction.

- Q: Is graphite a high molecular material?

- Polymeric materials: Materials based on polymer compounds. Polymeric materials are made of compounds with relatively high molecular weight, including rubber, plastics, fibers, coatings,

- Q: What is the difference between graphite and activated carbon?

- Activated charcoal is a mixture with good adsorption capacity obtained by carbonization and pore-forming treatment directly with wood, coconut shell and so on. It contains organic or inorganic functional groups, which is a dense pore structure.

- Q: Activated carbon fiber or activated carbon fiber

- In the field of carbon fiber is the same.I personally think that the history of misunderstanding is like this, early years of science and technology in Japan developed, they love to use "charcoal", the international community only know "charcoal", we have to use charcoal. , The State Text Working Committee in the planning of Chinese characters has been working, the domestic periodicals and magazines have changed to carbon.

- Q: What is the difference between the adsorption of graphene and activated carbon

- The size of the adsorption capacity often like to use the specific surface area to measure ... and the specific surface area of graphene is much larger than the activated carbon ... but graphene is not like activated carbon ... there are a lot of microporous structure ...

- Q: Why just renovated the house put plants, activated carbon, bamboo charcoal, the taste is still great

- Do not believe that formaldehyde self-test box, I measured anywhere in my home are 0.1, including outdoor.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2007 |

| Annual Output Value | US$ 10 Million - US$ 50 Million |

| Main Markets | 20.00% North America 20.00% South Asia 10.00% Middle East 10.00% North America 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Eastern Europe |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered. |

| Product Price Range | High; Average |

Send your message to us

Artificial Graphite(MCMB) For Lithium Ion Battery

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20MT m.t.

- Supply Capability:

- 120000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords