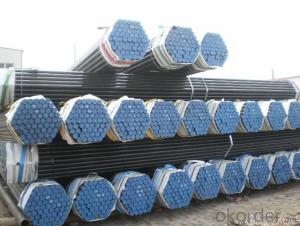

API 5CT Casing Pipe for conveyance of gas, petroleum, liquid and electricity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technique Parameters

Casing Technical Specification (Standard API Spec 5 CT) | |||||||

Size | Outside Diameter | Inside Diameter | Grade | Wall Thickness | |||

in | mm | in | mm | in | mm | ||

4-1/2 | 4.500 | 114.30 | 4.000 | 101.60 | J55K55N80 | 0.250 | 6.35 |

3.920 | 99.57 | J55K55N80 | 0.290 | 7.37 | |||

5 | 5.000 | 127.00 | 4.408 | 111.96 | J55K55N80 | 0.296 | 7.52 |

4.276 | 108.61 | N80P110 | 0.362 | 9.29 | |||

4.126 | 104.80 | N80P110 | 0.437 | 11.10 | |||

5-1/2 | 5.500 | 139.70 | 4.892 | 124.26 | J55K55N80 | 0.304 | 7.72 |

4.778 | 121.36 | N80 | 0.361 | 9.17 | |||

4.670 | 118.62 | N80 | 0.415 | 10.54 | |||

7 | 7.000 | 177.80 | 6.366 | 161.70 | J55K55N80 | 0.317 | 8.05 |

6.276 | 159.41 | J55K55N80 | 0.362 | 9.19 | |||

6.184 | 157.07 | N80 | 0.408 | 10.36 | |||

9-5/8 | 9.625 | 244.48 | 8.755 | 222.38 | N80 | 0.435 | 11.05 |

8.681 | 222.50 | N80 | 0.472 | 11.99 | |||

10-3/4 | 10.750 | 273.05 | 10.050 | 255.27 | H40J55K55N80 | 0.350 | 8.89 |

9.850 | 250.19 | J55K55N80 | 0.450 | 11.43 | |||

13-3/8 | 13.375 | 339.72 | 12.615 | 320.42 | J55K55 | 0.380 | 9.65 |

12.415 | 315.34 | J55K55N80 | 0.480 | 12.19 | |||

- Q: How are steel pipes connected together?

- Steel pipes are typically connected together using various methods such as welding, threading, or using mechanical fittings, depending on the specific application and requirements.

- Q: Can steel pipes be insulated for thermal efficiency?

- Yes, steel pipes can be insulated for thermal efficiency. Insulating steel pipes helps to reduce heat loss or gain, ensuring better energy efficiency and cost savings. The insulation material, such as foam or mineral wool, is typically wrapped around the pipe to create a barrier that minimizes heat transfer.

- Q: How do you determine the wall thickness of a steel pipe?

- There are several methods available for determining the wall thickness of a steel pipe. The most commonly used and precise approach involves utilizing a caliper or micrometer to measure it. Initially, ensure that the pipe is thoroughly cleaned and devoid of any debris or rust. Subsequently, gently position the caliper or micrometer around the circumference of the pipe, making certain that it is perpendicular to the surface. Proceed to cautiously close the jaws of the measuring tool until they snugly fit against the pipe, taking care not to excessively tighten them and distort the shape. Once the jaws are closed, observe and take note of the measurement displayed on the tool. This reading corresponds to the distance between the inner and outer diameter of the pipe, which is equivalent to the wall thickness. Alternatively, if a caliper or micrometer is unavailable, a pipe wall thickness gauge can be utilized. These gauges are equipped with a series of pins or rollers that can be inserted into the pipe, providing an accurate measurement. Simply insert the pins into the pipe, ensuring proper alignment with the wall, and refer to the reading displayed on the gauge. It is crucial to note that when measuring the wall thickness of a steel pipe, multiple readings should be taken at various points along the pipe to account for any variations. This will yield a more precise average measurement.

- Q: What is the fatigue strength of steel pipes?

- The fatigue strength of steel pipes refers to the maximum stress level that the pipes can endure without experiencing fatigue failure or damage over a given number of stress cycles. It varies depending on factors such as the steel composition, manufacturing process, pipe dimensions, and environmental conditions.

- Q: Is there a weld on the outer wall of seamless steel tube?

- Seamless steel pipe's inner wall, outer wall, section, cross section can not see the weld seam. Because seamless steel pipe is a molding product, no late roll pressure, welding and other processes. No section, inner wall, outer wall or section, as long as there is weld, it is not seamless steel tube. The inner wall can not see the outer wall of welding seam, but it can be seen that the weld products are fake or polished goods. Some products can not be seen without friction and have weld seams on the outside wall. They are seamless treated steel tubes and are polished goods. The price is much different from the real seamless steel tube. Some bad wounding, confusing concepts, earn illegal profits.

- Q: Are steel pipes suitable for offshore drilling platforms?

- Steel pipes have been widely used in offshore drilling platforms because of their strength, durability, and resistance to corrosion. These platforms operate in harsh marine environments, where they are exposed to saltwater, extreme pressure, and temperature changes. Steel pipes are capable of enduring these conditions and serving as a reliable and long-lasting solution for transporting fluids, such as oil and gas, from the seabed to the surface. Moreover, the ability to weld steel pipes together facilitates their easy installation and maintenance on offshore drilling platforms. In conclusion, steel pipes have proven to be an appropriate choice for offshore drilling platforms due to their robustness and ability to withstand the challenging conditions of the marine environment.

- Q: Can steel pipes be used for conveying oil?

- Steel pipes are suitable for the transportation of oil. In the oil and gas industry, steel pipes are widely utilized for the conveyance of oil due to their robustness, longevity, and resistance to corrosion. The exceptional strength of steel pipes enables them to endure the demanding conditions of high pressure and temperature that often accompany oil transportation. Furthermore, steel pipes are less susceptible to leakage and damage in comparison to alternative materials, thus making them a dependable choice for the efficient transfer of oil over extensive distances. Moreover, the sleek interior surface of steel pipes aids in reducing friction and improving the oil flow. Overall, steel pipes are the preferred option for oil transportation owing to their superior mechanical properties and enduring performance.

- Q: What are the different types of steel pipe bends?

- There are three main types of steel pipe bends: 90-degree bends, 45-degree bends, and 180-degree bends. These bends are commonly used in piping systems to redirect the flow of fluids or gases in a desired direction.

- Q: Can steel pipes be used for offshore applications?

- Yes, steel pipes can be used for offshore applications. Steel pipes are commonly used in offshore oil and gas drilling operations, as they have high strength, durability, and resistance to corrosion, which are essential qualities for withstanding harsh marine environments. Additionally, steel pipes can be easily welded and fabricated to meet specific offshore project requirements.

- Q: What is the lifespan of steel pipes?

- The lifespan of steel pipes can vary depending on various factors such as the quality of the steel, usage conditions, maintenance, and external factors like corrosion. However, properly installed and maintained steel pipes can typically last for several decades or even a century.

Send your message to us

API 5CT Casing Pipe for conveyance of gas, petroleum, liquid and electricity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords