Wear Resistant Composite Anti-Corrosion Clear Fiberglass Tubes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Filament winding is a molding process. Fiber glass roving is pulled through a bath of catalyzed resin and

impregnated. The resin impregnated roving is wound under tension on to a cylindrical. The composite material cures and the mandrel is removed. Filament winding is used to make high strength, hollow, and typically columnar composites, such as pipe, fitting and storage tanks.

FEATURES

Corrosion resistance High mechanical property

Low friction coefficient

Light weight

Non toxic

Maintenance free

Long life span

Double O ring sealing joint make the pressurization more convenient and unique.

Convenient and quick installation

Long life of more than 50 years

TECHNICAL DATA

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

1000 | 14.6 | 13.7 | 13 | 16.2 | 15.1 | 14.4 | 20.7 | 18 | 17.3 |

1100 | 16.1 | 14.9 | 14.2 | 17.9 | 16.5 | 15.6 | 23 | 19.8 | 18.9 |

1200 | 17.2 | 16.1 | 15.4 | 19.6 | 17.9 | 16.9 | 24.7 | 21.5 | 20.6 |

1400 | 20.4 | 18.4 | 17.7 | 22.7 | 20.5 | 19.5 | 29.2 | 24.8 | 23.8 |

1500 | 22 | 19.9 | 18.7 | 24.4 | 22.1 | 20.7 | 31.4 | 26.3 | 25.3 |

1600 | 23.6 | 21.2 | 20 | 26.2 | 23.4 | 22 | 33.7 | 28.2 | 26.9 |

1800 | 26.3 | 23.5 | 22.4 | 29.2 | 26.1 | 24.7 | 36.4 | 31.6 | 30.3 |

2000 | 27.4 | 25.4 | 23.4 | 35 | 32.4 | 29.6 | 44.7 | 37.3 | 36.1 |

2200 | 29.7 | 27.6 | 25.3 | 37.8 | 35.3 | 32.6 | 48.7 | 41.5 | 40.4 |

2400 | 32.6 | 30.3 | 28.4 | 41.8 | 38.8 | 34.6 | 53.4 | 44.6 | 42.8 |

2600 | 36.3 | 33.5 | 31.5 | 45.2 | 40.5 | 35.4 | 55.8 | 47.2 | 45.6 |

2800 | 39.6 | 36.0 | 34 | 49.4 | 45.1 | 42 | 62 | 53 | 51 |

3000 | 41.0 | 38.1 | 36.2 | 52 | 47 | 45.3 | 67 | 58.2 | 54 |

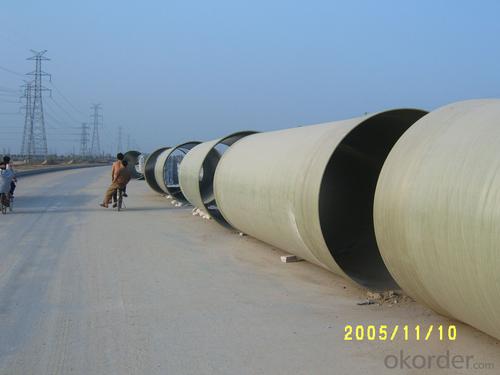

PICTURES

- Q: FRP pipe and 0.7 thick galvanized pipe which cost is low?

- Glass steel pipeline, FRP pipe and 0.7 galvanized steel pipe glass steel pipes cost is obviously low, FRP pipe material factory manufacturing costs and labor costs are relatively low, the price is only about the same thickness of galvanized pipe 60-70%, I hope you can help!

- Q: CGCT what's the meaning of the GRP sand pipe?

- Glass reinforced plastic sand pipe is actually in the production of glass fiber reinforced plastic pipe, in the middle to increase a layer of sand layer, the purpose is to increase the rigidity of the pipeline.

- Q: What qualifications do FRP pipes need to export to Australia?

- Need to comply with the local certification standards or international certification standards certification system

- Q: How to install FRP pipe correctly

- And glass fiber reinforced plastic parts (three, elbow, etc.) in general, the best way is on-site bonding, quality stability and convenience.

- Q: What is the compressive strength of all kinds of FRP materials?

- Anti fouling and anti moth: unsaturated polyester resin surface clean and smooth, will not be ocean or sewage in the shellfish, fungi and other microorganisms stained, moth, so as to increase roughness, reduce water cross section, increase maintenance costs. FRP pipes are free from these pollution and are clean for a long time. At the same time, because of its smooth inner wall and excellent corrosion resistance, it will not cause scale and microbial growth, effectively guarantee water quality and maintain the stability of water resistance. But the traditional pipe still exist after water resistance increases and the surface fouling phenomenon.

- Q: What are the main points for the installation of FRP ducts?

- Underground parking, commercial and residential buildings, shopping malls, civil air defense projects, office buildings and so on

- Q: What is the elastic modulus of glass fiber reinforced plastic?

- If so, the modulus of elasticity is 72000MPa, and the glass is isotropic, so the modulus of elasticity in the three directions is the value.

- Q: Excuse me, what standard does the glass fiber that check mechanical and electrical use accord with GB?

- FRP insulated pipe is a kind of light, high strength and corrosion resistant nonmetal pipe.

- Q: What are the posts of glass fiber reinforced plastic sand pipe and the corresponding occupational hazards and protection?

- Glass fiber reinforced mortar pipe lightweight high strength: for the same diameter of the unit length, weight, RPM tube only carbon steel 1/3, cast iron pipe 1/5, prestressed concrete pipe 1/10, easy transport, loading and unloading.

- Q: How can FRP tanks be connected to steel tubes?

- FRP pipe and glass fiber reinforced plastic fittings (three passes, elbows, etc.) generally speaking, the best way is on-site bonding, the quality is stable and convenient.

Send your message to us

Wear Resistant Composite Anti-Corrosion Clear Fiberglass Tubes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords