Aluminum/Polyester Composite Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description:

Usually as a middle layer the data according to the requirements, composite bag mainly film substrate: outer printing BOPA film BOPETBOPP inner heat sealing film CPPPE and co extruded film. AL aluminum foil) is one of them. Plastic bucket sealing machine through the glue composite film!

2. Product Characteristic:

1. Aluminum foil bag with metallic luster. And the aluminum foil bag printing color is more exquisite and bright. Maintenance performance is strong.

2 .aluminum foil bag is good. Has the characteristic of gas and water vapor impermeable, blister sealing machine which can effectively prevent the contents of moisture absorption and gasification and less susceptible to bacterial and insect pests, shape, and good stability, is not affected by changes in humidity.

3. Using the shielding or elution of local aluminum

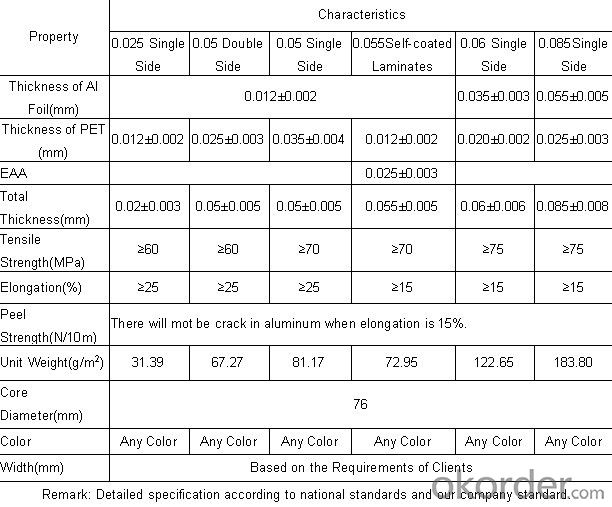

3.Specification :

4. Reference Picture:

- Q: What is the reason why the packing belt breaks easily?

- When the operator does not wait for the back of the pallet on the packing machine, the goods will be moved down and the hot melt surface has not been condensed

- Q: The harm of plastic packing belt to human body

- If you eat into the abdomen, if you can discharge with feces, it will not cause harm to the human body, unless it is hard plastic, easy to scratch the stomach wall and intestinal tract. Please look at my head, professional manufacturers, quality assurance.

- Q: Blue belt principle is what?

- Also known as orchid. The black metal surface by the "blue bluing" after the formation of the oxide film, the outer layer is mainly magnetite, the inner layer is feo.

- Q: Why is plastic strapping broken?

- Is there any quality problem? The packing bags are all made of their own masterbatch. A serious imbalance in the proportion lead to too brittle packing belt. Or stored for a long time, long sunny rain. It might get crispy. Originally, the quality of plastic belt maintenance time is very long, it is a substitute for steel belt in horizontal wet packaging environment. It should be low cost and strong breaking force.

- Q: What kind of joints are used in the packing belt?

- Hot dip lap pack.Hot melt lapped by electrothermal welding, packing machinery high-frequency welding and ultrasonic welding and heating method, plastic surface heat melting, two with end face lapping up melting under pressure, to maintain a certain period of time, to be melted surface condensation, adhesive plastic belt joint way. Features: hot lap package is a package of new, suitable for polypropylene plastic bag, polypropylene plastic belt with iron because if the button is fixedly connected with the mechanical strength, only 50% of that of the base material, adhesive connection does not apply. The excuse is firm and beautiful, but it can not be untied.

- Q: Identification of PP packaging belt

- The packing machine should have a gloss, so the strapping machine is usually made of whole material. Tensile stability. Packaging machine with powder powder, then the gloss will be greatly reduced.

- Q: How much is a tin strap?

- Usually by weight to sell, a kilogram of about 3 yuan or so. The surface lubricating strip, reduce the friction resistance between the strip and strip between packaging and packaging, in order to make the packing strip tightening more firmly; the edge smooth edges, avoid packaging and packaging to scratch the rower.

- Q: What's the packing case for the pull case?

- Tie the tie bar box to prevent shipment on the way

- Q: How should the packing tape be printed?

- Want to print a good pack of words, three can not be less:1., with the belt before embossing, the blank surface must be smooth and uniform, not one side thick, one side thin.2., the production of printing wheels to be precise, smooth and smooth surface, easy to scrape ink, ink should be thick and shade.3., the packing belt before and after the fixed to be accurate, keep the printing wheel and packing belt between not too big jitter, drive must be stable.

- Q: Baling machine; packing belt; tightness adjustment

- The automatic packer can not work automatically. First need to control system of packing tape to check whether the normal position, with a long adjustment is in the zero scale, and then check whether the wear process conforms to the standard, generally there are foreign bodies blocked, causing this kind of phenomenon.

Send your message to us

Aluminum/Polyester Composite Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords