VIP Boards Alumina Foil Cover Insulation Board for Steel Plant with Micropore Heat and Thermal Insulation Layer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

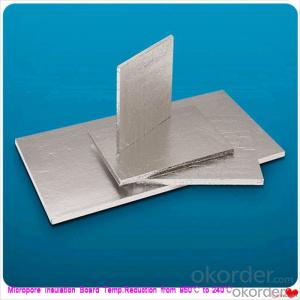

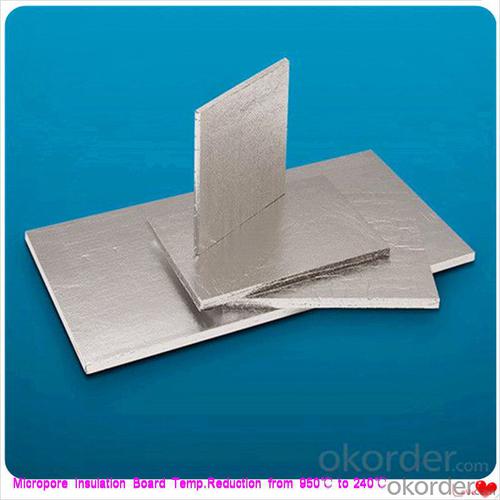

Alumina Foil Cover Insulation Board Steel Plant Using Micropore Heat and Thermal Insulation Layer

Product Description for Alumina Foil Cover Insulation Board

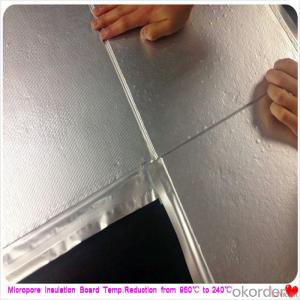

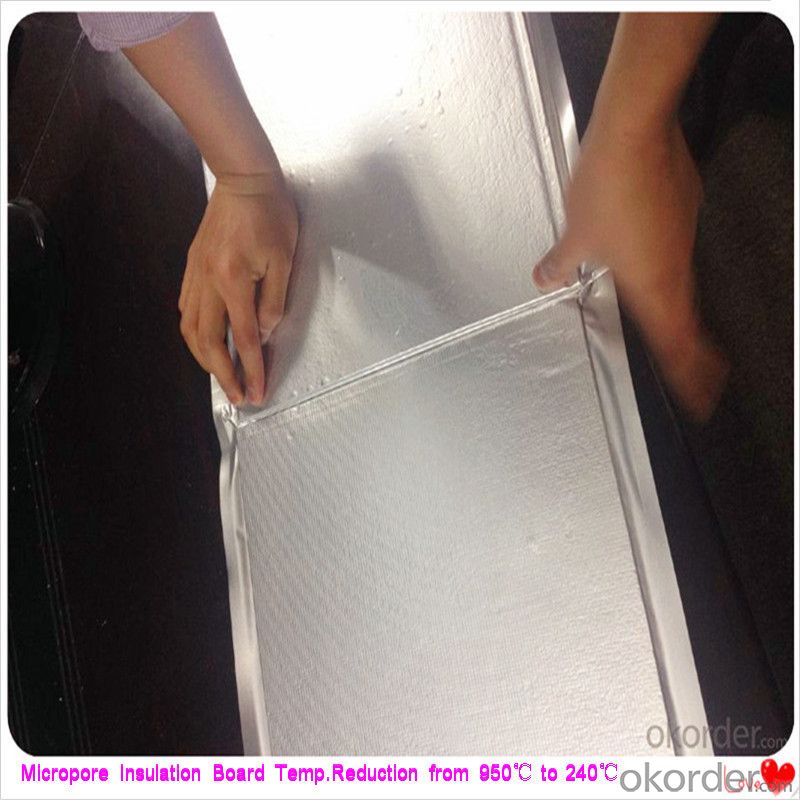

CMDS Microporous Insulation Boards are specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous insulation boards when moisture may occur due to castables, mortar etc.

Micropore Insulation Boards can be as much as four times more effective than conventional insulation materials. In practical terms this means that a Micropore Insulation Boards system can be only one quarter of the thickness for equivalent thermal control. This becomes crucially important wherever space is limited.

Our MIP is new product for industrial application such as Ladle, Torpedo ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Kiln, Aluminum Melting and Holding Furnace and so on. Its name is micropore or micrporous insulation boards.

Microporous insulation boards are specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to unshaped material such as castables, mortar etc.

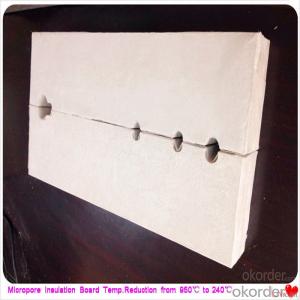

It has many advantages such as its extremely low thermal conductivity, high compressive strength, high thermal stability, environment protection, easy to handle, no harmful inhalable fibers, resist most chemical attacks and free of organic binders and non combustible. Microporous insulation boards can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Structure& Advantage for Alumina Foil Cover Insulation Board

for Micropore/ Microporous Insulation Boards with Alumina Foil Cover

1) Extremely low thermal conductivity

2)High compressive strength

3)High thermal stability

4) Environment protection

5) High thermal stability

6) Environment protection

7) Easy to handle

8) No harmful inhalable fibers

9) Resist most chemical attacks

10) Free of organic binders

Benefits Our Insulation Products Brings You:

1. Reduce the kiln wall thickness from 455mm to 380mm, nearly 16%!

2. Decrease the heat loss of the kiln wall.

3. Save the cost of installation and shorten production lead time by using less material.

4. Shorten the refractory roller length needed for the same capacity kiln.

So after all , you just need invest once in the beginning, and it is the pay-back time of the investment by reducing energy , and heat loss , enlarging space in the following days !

We Are The Major Suppiler for

Using our Micropore/ Microporous Insulation Boards with alumina foil cover

Allied Mineral Products,inc

Refractories Incorporated

SRS Sorg Refractory Systems GmbH, (Germany)

Sunward Refractories Co.,Ltd

Lilama69-1 Joint Stock Company etc.

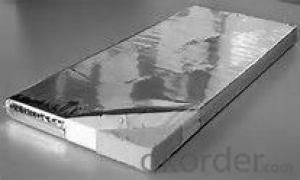

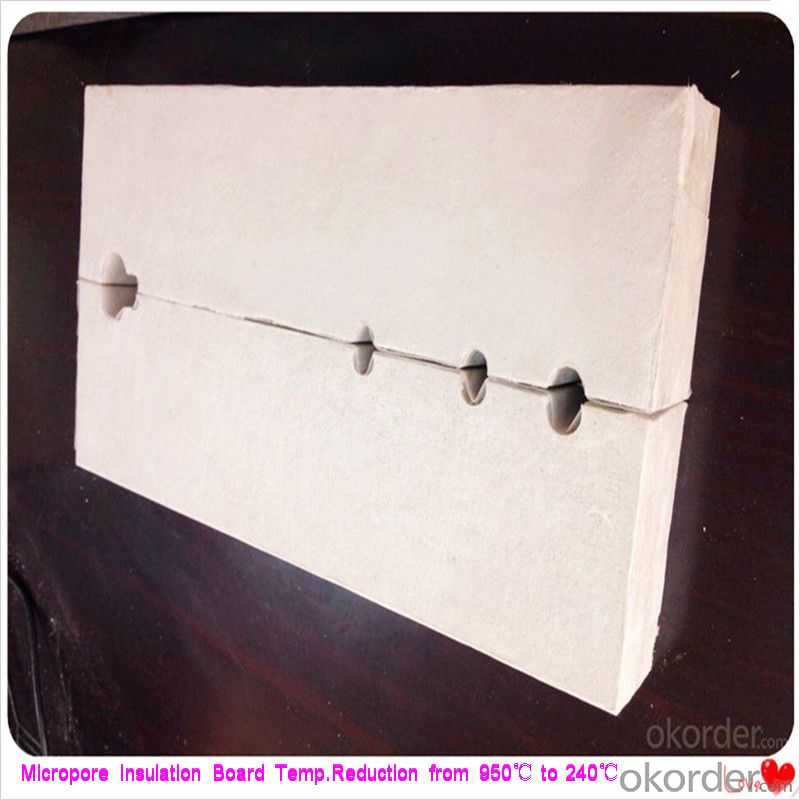

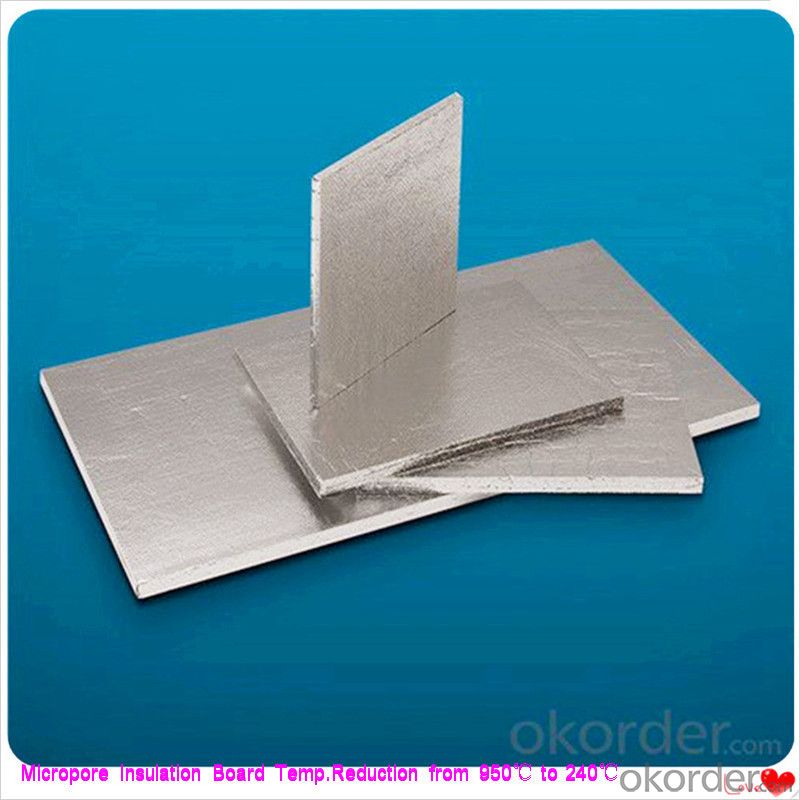

Major Images for Alumina Foil Cover Insulation Board

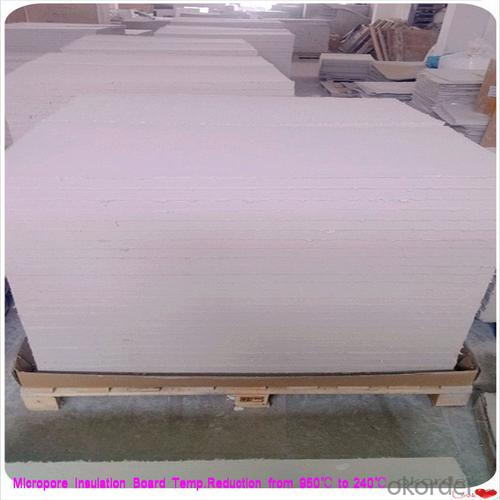

Packaging & Delivery for Alumina Foil Cover Insulation Board

Package:each pallet size1100 x 1300 x 1200mm, and packing with plastic foil or case. usually use plastic foil.

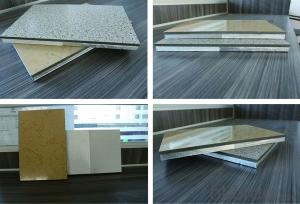

Application Images for Alumina Foil Cover Insulation Board

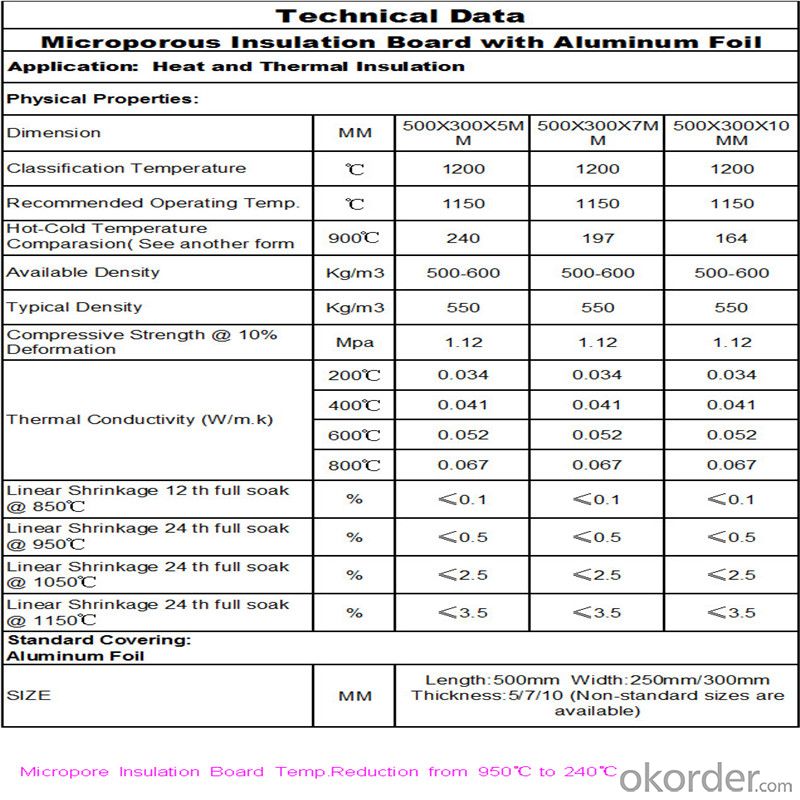

Specification Data for Alumina Foil Cover Insulation Board

FAQ

Q1:Are you a manufacturer or trader?

A:Manufacturer+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different Microporous Insulation Boards: Micropore/ Microporous Insulation Boards is unlike.It also depends on your using condition and method.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services in 24 hours!!

- Q: I ask, our home is the top floor, the summer is too hot, the walls and roof in addition to the use of insulation board, posted their own kind of tin foil, will not be useful?

- The traditional ceiling color steel tile composite composite 10 cm thick white polystyrene foam insulation board, the insulation effect is not very good, this is because the thermal conductivity of polystyrene foam board is relatively high (thermal conductivity 0.035W / (m · K) above), plus There is a gap between the foam board and the board, the temperature is very serious, the comprehensive thermal conductivity is generally higher than 0.05. The new polyurethane spray insulation material can be directly sprayed on the color steel tile, the thermal conductivity is low, only 0.022-0.024W / (m · K), insulation effect is 2-3 times the polystyrene board, is the insulation of all insulation materials Especially excellent material. Because in the construction of the use of direct spray molding technology, so that the polyurethane foam layer is not the overall burden of sewing the body to form a complete impermeability, fundamentally put an end to the possible deep Sex. Which play a preservative effect.

- Q: Is the thermal conductivity of the vacuum insulated plate used to protect the hot plate method?

- This place is different in different places, the calculation is not the same. We are here so: independent columns need to calculate the scaffolding to (peripheral circumference +3.6) multiplied by the column height calculation, 3.6 meters below the single row of scaffolding, 3.6 meters above the corresponding height of the double row. With the overall beam of the beam does not calculate the scaffolding. You say the frame column, to distinguish between different situations.

- Q: What brand of refrigerator is using a vacuum insulation board? What kind of insulation board is better? More

- What do you mean if you want to get your own steel pipe fastener? Which city is in the city?

- Q: What is the best insulation material? To be waterproof.

- XPS board has a unique micro-closed-cell honeycomb structure, compared with the EPS board, with a high density, high compression performance, thermal conductivity is small [building buildings commonly used XPS board at room temperature thermal conductivity of about 0

- Q: External wall insulation material which is good, external wall insulation materials

- Indoor insulation material that the best, fire, environmental protection, good insulation effect? ??Glass fiber. Good insulation. Glass fiber cotton with numerous fine gas holes, fibers arranged irregularly arranged, heat conduction breakdown of 0.03w / cm.k, is an excellent insulation material; . with non-flammable. Glass fiber cotton will not burn, no deformation, no embrittlement, can withstand 700 degrees of high temperature, the combustion performance to A1; . environmental non-toxic. As the glass fiber cotton in the manufacturing process does not add any adhesive, so there is no smell, high temperature will not be distributed when the toxic, pungent smell, smell, etc .; . high insulation. As the glass fiber cotton used in the raw material is glass, non-conductive, so it has a very high insulation; . corrosion resistance. Glass fiber is not afraid of strong acid, with a strong corrosion resistance, even if the use of long time will not reduce its functional characteristics; . good recovery Glass fiber contains numerous fixed cavitation, with excellent recovery, not afraid of any shock, tensile strength are more than 1.0kg; . do not want to light field scrambled decanoate containing mutual water. The moisture absorption of glass fibers is usually close to zero, do not worry about there will be water swelling caused by wet cracking of the situation. I hope my answer can help you.

Send your message to us

VIP Boards Alumina Foil Cover Insulation Board for Steel Plant with Micropore Heat and Thermal Insulation Layer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords