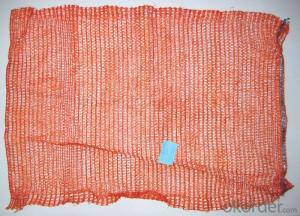

Agricultural Mesh Bag 25G for Fruit, Vegetable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name of Agricultural Mesh Bag 25G for Fruit, Vegetable:

PE Mesh Bag VIOLET

Loading Port: Shanghai port, China

Min.order quantity: 1*20GP

Supply Capability: 20*40HC per month

Payment Terms: TT or LC

Introduction of Agricultural Mesh Bag 25G for Fruit, Vegetable:

This products is made by HDPE (High-Density Polyethylene) or PP (Polypropylene), it is used for packing olive, onions, potatoes, and so on.

Specification of Agricultural Mesh Bag 25G for Fruit, Vegetable:

30x50cm, 40x60cm, 42x70cm, 50x80cm, 55x78cm, 55x85cm, 57x86cm, 60x90cm, etc.

Width and length are as customers’ request.

Color: red, green, yellow, white, pink, orange, purple, as per your requirements

Top: Hemmed or locked, with drawstring or without, handle is available

Bottom: Single fold or double fold. Single stitch or double stitch

Printing: on one side or both sides, in one color or multi-colors

Application of Agricultural Mesh Bag 25G for Fruit, Vegetable:

It can be used packing onions, potatoes, apples, orange and other vegetables or fruits. It can hold heavy enough produces

FAQ of Agricultural Mesh Bag 25G for Fruit, Vegetable:

Q: How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q: How long can we receive the product after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 30 to 35 working days can be served.

Q: HOW TO GET A SAMPLE?

A: FREE samples for Agricultural Onion Mesh Bag 40g HDPE Material are available for your checking and testing. And to get free samples, you need to send us you detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side.

- Q: hey can anybody body provide me with 5 or more resolutions to aviod plastic and products as far as possible.

- 1.canvas shopping bags instead of plastic ones 2.Get rid of your plastic dishes and cups, and replace them with glass varieties 3.Avoid products that are packaged in plastic 4.stainless steel water bottle instead of plastic bottles 5.stopped using plastic dish scrubbies to wash dishes. I now use Twist sponges, which are all natural and biodegradable. 6.)I stopped buying cream hand lotion, instead lotion that comes in a metal tin 7.)I return my styrofoam egg cartons

- Q: What are the different types of agricultural plastic labels and tags?

- There are several types of agricultural plastic labels and tags, including seedling labels, plant markers, fruit and vegetable tags, livestock identification tags, and pesticide labels. Each type serves a specific purpose in the agricultural industry, helping with plant identification, tracking livestock, and providing important information about seeds and chemicals used in farming.

- Q: Can nursery trays be used for perennial divisions?

- Yes, nursery trays can be used for perennial divisions. Nursery trays provide a convenient and organized way to separate and grow individual perennial divisions. The trays help maintain proper spacing and allow for easy handling and transportation of the divisions.

- Q: How does agricultural plastic affect crop yield and quality?

- Agricultural plastic can have both positive and negative effects on crop yield and quality. On the positive side, plastic mulch and row covers can help crops by increasing soil temperature, conserving moisture, suppressing weeds, and reducing the spread of diseases. These benefits can lead to higher yields and improved crop quality. However, improper use or disposal of agricultural plastic can have negative consequences. Plastic debris left in the field can hinder crop growth, impede water and nutrient uptake, and create a breeding ground for pests and diseases. Additionally, plastic waste can pollute the environment and harm wildlife. Therefore, proper management and responsible disposal of agricultural plastic are crucial to maximize its benefits while minimizing any potential negative impacts.

- Q: what is plastic? it is what we use in our everyday lives and is molded and shaped and melted down and re-shaped but what is this substance where does it come from how is it generated and made. i tried researching it but the way it is broken down is like AP chemistry and i dont understand it so can someone breakdown what plastic is for me im just curiouse AP chemistry and i dont understand it so can someone breakdown what plastic is for me im just curious

- Plastic is made of atom chains. There are many different types of plastic, although A majority of plastic is made from Hydrocarbons, also known as Gas, oil, tar....All of these are hydrocarbons...although only some are allowed to make plastics. Each is prepared in a certain way So, they are mixed with other chemicals, or heated to a specific temperature. this is what plastic is.

- Q: I have a lot of german garten zwerge[little gnomes]have a lot of black spots from being outdoors,I guess how do I get rid of them.I heard a good plastic cleaner might do it.

- extremely tough problem. do a search over yahoo and bing. it might help!

- Q: Are agricultural plastic products resistant to chemicals?

- Yes, agricultural plastic products are generally resistant to chemicals. They are designed to withstand exposure to various agricultural chemicals, such as fertilizers, pesticides, and herbicides, without degrading or being negatively affected. This chemical resistance is due to the specific composition and manufacturing process of agricultural plastic products, making them suitable for use in farming and other agricultural applications.

- Q: Can I cook liverwurst in plastic wrap? (I don't have any casings nor muslum cloth). I have seen restaurants on tv use plastic wrap but I am thinking that this is special quot;heat proofquot; plastic wrap? Can I do this with every day plastic wrap from the regular store? Or?

- Plastic anything should never be heated because the heat will cause toxic substances to get onto your food. I'm thinking you are saying that you are going to fry this liverwurst. If so, just slice it off and fry it in hot oil in a skillet. It should stay together.

- Q: What are the benefits of using plastic mulch in agriculture?

- Plastic mulch offers several benefits in agriculture, such as improved soil temperature regulation, reduced weed growth, enhanced moisture retention, increased crop yield, and prevention of soil erosion.

- Q: I'm making a rabbit hutch and I#92; have strong plastic mesh, not the metal mesh. Would the rabbits chew through the plastic mesh? It's really closed mesh as well. Please answer :)

- Rabbits can chew pretty much any plastic. Even the hard plastic used to make some dishes or toys can be chewed by a determined rabbit. Plastic mesh is usually not too strong and could be easily chewed by a rabbit. With cages and anything that will contain a rabbit, metal or wire is best.

Send your message to us

Agricultural Mesh Bag 25G for Fruit, Vegetable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords