AGM SEPARATOR

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7.2MT

- Supply Capability:

- 18000 MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

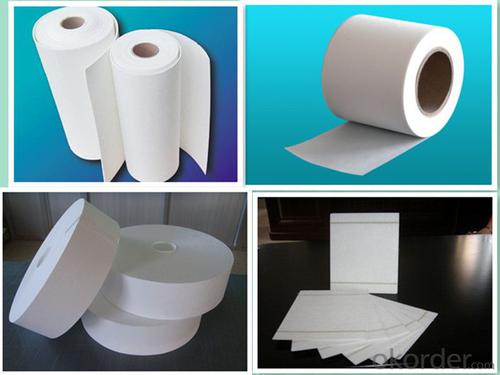

AGM Battery separator

AGM Battery separator is made of 0.5-2.5μm micro-fiberglass, by wet processing, which is with features of good acid-resistance, high pore rate, small pore diameter, high liquid absorption rate and low electrical resistance and so on. It is ideal separator for free maintenance valve control type battery. It is widely applied in UPS, and also field of fossil oil and chemical industry as adsorption, filtering and insulation material. The availabel thickness is from 0.5mm to 3.5mm. It is different thickness under different pressure. The normal pressure is 10KPA, 20KPA and 100KPA. Different pressure demand can be met as customer request. The finished goods can be supplied by cut tape roll or cut pieces.

Property:

Apearrance | White, no hole | Pore rate (%) | >92 |

Thickness (mm) | 0.5~3.5mm(100KPA) | Tensile Strength(Kg/c) | >0.42D |

Loss weight after dipping acid | ≤3% | ||

Height for absorbing acid | ≥75mm/5min | Fixed value(G/m2.mm) | ≥140g(10kpa) |

Liquid absorption rate (%) | ≥900 | Fe content(%) | 0.004 |

Pore size (um) | ≤22 | Cl content(%) | 0.003 |

- Q: Which car is suitable for daily leisure? What are the areas of care for future maintenance? Is there any other recommended mountain bike?

- Or Giant and Merida it, for the future maintenance of a lot of things, the daily leisure, then ATX680 it, the price of 1380 or so, feeling Hanute is too heavy, this light a lot, look at their own budget it, choose space quite big

- Q: For example, the former surrounded by large, side skirts, tail, rear lights, rear cover, and so there are some other small parts of the name, as long as the outside can see more. It is best to bring the name of the English, written in front of those I have already know.

- Hood, windshield, front light, intake grille, rearview mirror, front fender, A, B, C pillar, front and rear doors, side lights (lights, turn lights), large siege, rear fender , Trunk, rear lights, license plate, car standard, nameplate, exhaust pipe, reversing radar, bumper, tires, wheels, sometimes visible disc brake.

- Q: Huanghua the original auto parts mainly produce what parts and components

- What parts are the main parts of the car

- Q: Anti-corrosion of automobile body (including commonly used protection methods, process, etc.)

- The basic method of car body corrosion is painted with a car body.

- Q: Which parts of the auto parts manufacturer?

- Penglai Wanshou, we have been very happy cooperation ~

- Q: What parts of the car will use the spring?

- Electrical categories: generator within the carbon brush spring, ignition switch back spring,

- Q: Ready to buy a car, fancy Mazda new CX5, although it is made, but there are many parts from Japan, fear of Fukushima nuclear radiation risk, I do not know what the views of nuclear radiation

- I know the metal will not carry radiation

- Q: What are the main parts of the car?

- Specified car experts said the analysis is very thorough

- Q: Car shell parts name Daquan

- Body shell, but then a few big pieces. Including the front hood, trunk cover, four doors, in front of two left and right leaves (commonly known as the front arm), the front bumper, rear bumper, the middle of the middle of the net also called the water tank grille. Of the body (including the roof after the leaf plate and the entire frame)

- Q: What do you do with running karting parts? The factory was not found before!

- At the bottom of the middle of the game page, there is a vehicle upgrade, the point that will enter a page, into the page after the upper left corner there are three options, the third is to strengthen the components, point later you can see their existing factory parts , But if you want to rely on the production of energy in exchange for components can not now, because the system temporarily closed the content, the need for parts, then there are two ways, the first is directly in the store to buy red / blue parts box, but out Of the components are not very good, the second method is through the activities of the gift of gold / silver parts to get the factory parts, silver parts of the components to open 100% are more than high, and gold parts of the box are open components Rare or above, in addition, the activities of the gift of gold / silver gift box can also open to the gold / silver parts box, I hope my answer can help you!

Send your message to us

AGM SEPARATOR

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7.2MT

- Supply Capability:

- 18000 MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords