Aerosol Can Testing Machine for Can Making

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

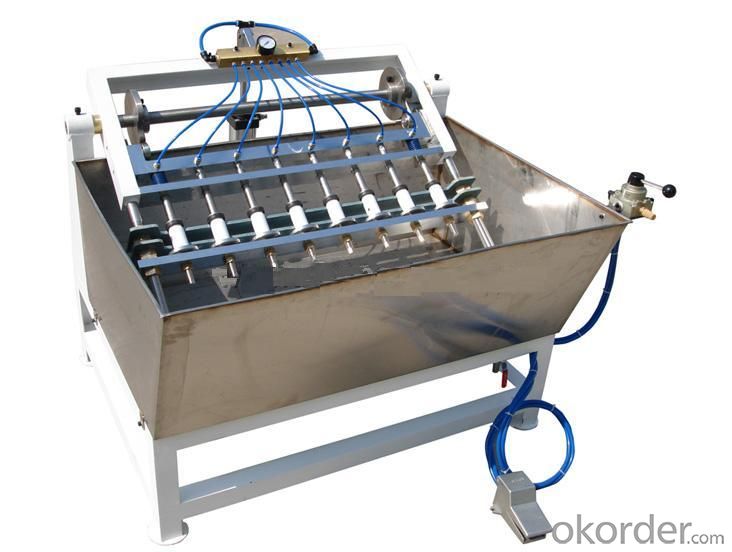

Aerosol Can Testing Machine for Can Making

1. Product Description:

The aerosol can water bath testing machine is a fully automatic testing machine for leakage or burst test. It’s a fully automatic testing machine for leakage or burst test with production capacity up to 80 CPM. The submersion clip design allows you to easily see a leaking valve cup while the can is totally submerged. It is available for 1" valves.

2. Product Features:

14 years’ experience

High quality Endurance

On time delivery

Can making production line

Round can, square can, irregular can

3. Product Parameters:

Model | EST-P24 |

Can diameter | 45-65mm |

Can height | 80-320mm |

Detectable leak | up to 2cc/10bar/min |

Capacity | 200cpm |

Working heads | 24 heads |

Air pressure | 8 to 10 bar |

Air consumption | 3m/3min |

4. FAQ:

Q: 5, Q: Can you do a business plan for a start-up company?

A: On request, at a fee.

Q: Do you have a warranty on your machines?

A: 12 month warranty from time of loading.

Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components

Q: Do you have instruction manuals?

A: We provide you with instruction manuals, electricity layouts, civil requirements, and machine drawings.

5. Product Pictures:

- Q: Where is secondhand corrugated paper packaging machinery available?

- And in the packaging materials, carton packaging accounted for a large part of the weight.Therefore, the carton factory is still very optimistic about the prospects.Business is best to have their own, if not, it is like playing a battle without vigor.But if you have better personal skills, you can also sell it to someone else's factory.After all, it is impossible to have friends and relatives need cartons, no "relationship" can be bigger and stronger.

- Q: What is the design basis of automated packaging?! Just for today!

- Greatly improve the degree of automation of process flowA few years ago, automation technology accounted for only 30% of the design of packaging machinery, now has accounted for more than 50%, a large number of micro computer design and mechanical and electrical integration control. To improve the packaging machinery automation, one is to increase productivity; the two is to improve the flexibility and agility equipment; three is to improve the ability of packaging machinery to complete the complex action, namely the manipulator to complete the packaging process. Such as chocolate packaging has been achieved, with mechanical hand instead of the original manual. Automatic design of packaging machinery has the following two main characteristics:

- Q: The role of food packaging machinery

- (8) can promote the development of packaging machinery related industry is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, the overall performance of any discipline problems will affect the packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.Fig. 3 is a flow chart of liquid filling. With empty bottles of boxes stacked on pallets, by the conveyor belt to depalletizers, will remove the tray one by one, the box with the conveyor belt to the machine, remove the empty bottles from the box, empty by the conveying belt to the washing machine, after cleaning, and transported to the packing machine next to filled with beverage bottles into them. The empty bottles removed from the unloading machine are sent into the bottle washing machine by another conveyor belt for disinfection and cleaning. They are tested by the bottle inspection machine and conform to the cleaning standard and then enter the filling machine and capping machine. The beverage is bottled from a filling machine. Packed beverage bottle capping machine with the sealed and transported to the labeling machine labeling, (see pictures) with various beverage bottle filling line of the process is similar. But because of the different nature of beverage, the filling machine and capping machine are also different.

- Q: What are the main plastic forming processes?

- 5. low pressure molding. A touch or laminating method using a molding pressure equal to or less than 1.4 mpa.Low pressure molding is used to make reinforced plastic products. Reinforced materials such as glass fiber, textiles, asbestos, paper, carbon fibers, etc.. Most resins used are thermosetting, such as phenolic, epoxy, amino, unsaturated polyester, silicone and other resins.Low pressure molding includes bag pressing and spraying.(1) bag pressing forming. A method of forming a workpiece by applying fluid pressure to an elastomeric plastic between a rigid mold and an elastic bag by means of an elastic bag (or other flexible diaphragms). According to the different methods caused by fluid pressure, can generally be divided into pressure bag molding, vacuum bag molding and autoclave molding etc..(2) spray forming. When molding reinforced plastic products, a method of spraying a short cut of fibers and resins simultaneously onto a mold and solidifying them into an article by means of an airbrush is described.

- Q: What is the price of a small jujube packing machine?

- What is the price of a small jujube packing machine?

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;But to use the hot pressing machine there is to do bakelite mold. Our company specializing in the production of blister, in addition to help customers hot packaging, directly to the finished products to customers

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- This is really not sure, it can be said that any group, as long as the packaging products are required to use packaging machinery. Most of the products are now in need of packing. So it can be said that any group.

- Q: What is the working principle of the pillow packing machine?

- Some packaging machinery manufacturers, many varieties of products, in the purchase of packaging machines, I hope a device can pack all their own varieties

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Mechanical sales are nothing more than two points: first, equipment aging, need to update; two, equipment efficiency is low, need to improve. You don't know anything about the customer. Come up and sell the product. If you are a customer, I don't think you have the patience to listen

Send your message to us

Aerosol Can Testing Machine for Can Making

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords