AB Inorganic Fiber Glass Wool Vacuum Insulation Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

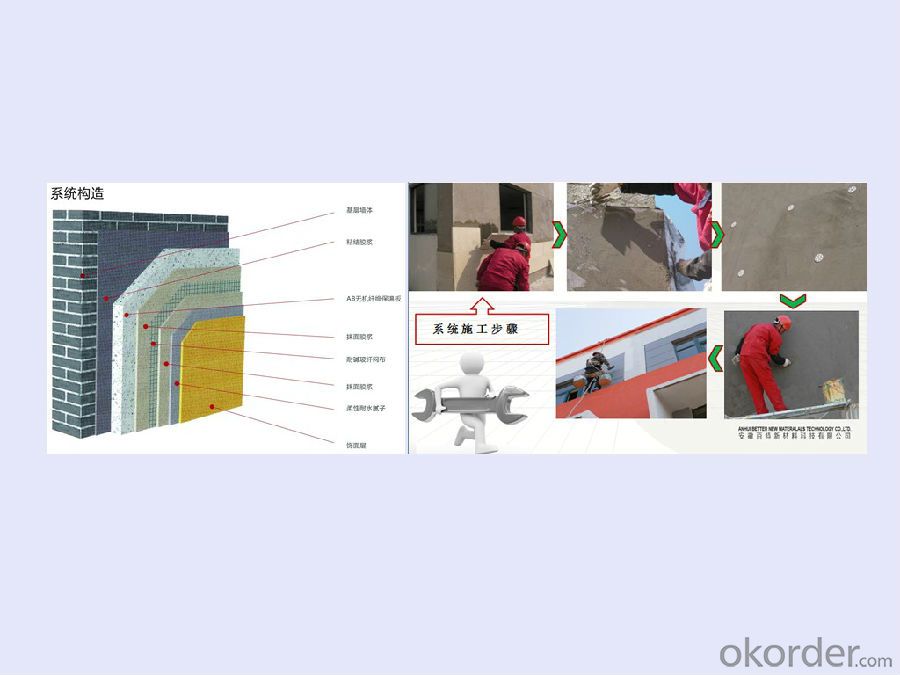

Product Introduction:

AB inorganic fiber insulation board is an insulation material that base on the Nano poro-us adiabatic principle, which comprehensive performance is outstanding and far beyond c-onventional insulation materials. The product is mainly compounded of ultrafine inorganic-c fibers, has Class A fireproofing, low thermal conductivity, convenient construction and more superior properties.

Range of application:

New construction, renovation, expansion of residential buildings, public buildings, and ind-ustrial buildings, where require insulation in winter or summer.

Feature:

Class A fireproofing, safety and reliability

Excellent insulation property

Great tensile, compressive strength

Good compatibility with the main structure, having same lifetime with the building

Green environmental inorganic insulation materials.

Superiority:

Advantage Ⅰ

Made from inorganic material, class A fire-proofing, noncombustible

Advantage Ⅱ

Superior thermal insulation property, thermal conductivity below 0.008W / (m·k), energy-saving effect is prominent

Advantage Ⅲ

Insulation effect is 3-8 times better than conventional insulation materials, it also means the

Insulation thickness is just one-eighth to one-third of the traditional insulation materials.

Advantage Ⅳ

Inorganic, non-toxic core materials, low-power, zero-emission process, no gas emission, no wate-r emission, the product is an environmentally friendly, low-carbon insulation material.

Advantage Ⅴ

Lighter, easier to transport and carrying, simplify construction technique-s, good paste effect.

Parameter:

Original strength≥1.0

Strength after soaking≥1.0

- Q: Does curtain wall glass wool belong to thermal insulation wool?

- In general, the outer wall heat preservation material should be distinguished with curtain wall thermal insulation material, curtain wall thermal insulation material is commonly mineral wool, and exterior insulation materials commonly uses polystyrene board, waterproof mortar and other composite materials.

- Q: What kind of glass wool is used for most buildings?

- Ask the dealer for product descriptions, and you can search its specifications and parameters and then design based on the performance specifications of specific products. I suggest you first determine which brand of thermal insulation cotton to use, or check if the number is in the tolerance range of national standards of the manufacturers, of course, it is a relatively wide range. I recommend Owens Corning ultrafine glass fiber insulation cotton.

- Q: Is the glass wool sound insulating? How good is it?

- Glass wool glass fiber is a kind of inorganic fiber in the category of glass fiber.The glass wool is of corrosion resistance, chemical stability, low thermal conductivity, low bulk density, thermal insulation and good sound-absorbing property. Besides, the chemical composition of glass wool is glass.

- Q: Centrifugal glass wool board and flexible foam rubber insulation, which one is better?

- Glass wool board has good fireproof performance and can endure higher temperature than the rubber material, which is cheap. Rubber material has poor fireproof performance. It has insulation performace no better than other materials.

- Q: Can Kunnai glass wool board and sound absorption blankets be used to maintain sound insulation in hotel floor? Can it decrease half of the noise? How to install?

- No estimate half, but still able to play a sound effect

- Q: Does anyone know about the general unit weight of glass cotton color steel?plate?

- Glass cotton is the general term of fibrous silicate minerals which can be split into long and narrow flexible fibers. Glass cotton are manufactured to meet the requirement of large-area pave, apart from the unique thermal insulation property, they are good at fireproofing, shock and sound absorption which help to reduce noise pollution, and improve working environment. The thickness of rock wool board : 40 to100 mm. The unit weight is 80 to 150kg / m?. Glass wool can be processe into different products. The thickness: 25 to 100mm. The unit weight is 30 to 80kg.

- Q: Is glass wool felt the mineral wool felt?

- No.

- Q: What are the specific differences between glass wool board and glass fiber board?

- Continuous fiber and staple fiber, glass wool board is equivalent to the glass fiber board, and the fiber used to make cotton is staple fiber. Thus. The fiber used to weave cloth is continuous fiber. There are two kinds from the use of glass fiber, the full name of glass wool is fiber glass wool.

- Q: What's the difference between the rock wool and glass wool board?

- Rock wool board is a kind of thermal insulation material that takes basalt or diabase as raw material and after processing into board, suitable for building exterior wall or roofing heat preservation, and it can also be used in the thermal insulation of large tanks, good strength, small water absorption, good thermal insulation properties, good machinability performance, superior fireproof?performance, the density can be up to 180 kg per cubic metre. Glass wool is made by taking silicon dioxide (glass) as raw materials and through processing, small density, light unit weight, thin fiber, little slag ball, good toughness and it can be bent randomly, and be processed into pipe, plate or blanket, etc., it's mainly used for heat preservation of light steel structure, overhead line (steam) or complex tanks, and it can also be used for the thermal insulation of steel set and steam pipe.

- Q: What are the functions of the thermal insulation glass wool board?

- Glass wool insulation materials are medium and low temperature thermal insulation materials, thus they are generally used in civil and cryogenic pipeline with the temperature of -120 ℃ -400 ℃. They can be used for thermal insulation and sound absorptionin in fields of construction, petrochemical, electric power and metallurgy.

Send your message to us

AB Inorganic Fiber Glass Wool Vacuum Insulation Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords