AAC Block Production Line,excellent, perfact

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

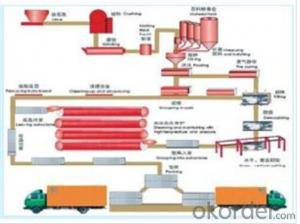

Introduction

AAC block production line, also known as aerated concrete block line, is a kind of lightweight block production line. According to different types of raw materials, quality and processing characteristics of equipment, AAC block machines are differently designed. The production process is as follows: Mix fly ash or silica sand, slag and water into slurry, stir the slurry together with powdered lime, a certain amount of cement, plaster and foaming agent, and then pour them into the mold box. After resting foaming solidification, AAC lightweight block production line can cut them into blocks or plates in various specifications, and then send them into the autoclave by the steam-curing car. After high temperature and high pressure steam curing, AAC block machine can produce porous and light aerated concrete products. Adopting German advanced equipment, PLC automatic feeding and complete electric control system, our lightweight block production lines are quite famous both home and abroad. The whole aerated concrete block line includes feeding, mixing, pouring, preliminary maintenance, cutting, autoclaved maintenance, and so on.

Use of AAC Block Machine

AAC lightweight block production line is widely used in industrial and civil constructions. We adopt the most mature technology of production to produce building materials.

Advantages of Aerated Concrete Block Line

1. Without any exhaust gas or waste residue, the production process of AAC block machine is in accordance with national environmental protection policy.

2. This lightweight block production line is equipped with a dedusting system for boiler gas and dust disposal which meet the requirements of smoke prevention and dust control.

3. Dust collector is used to improve the production environment and working condition.

4. Waste water and condensate water produced from AAC block machine can be recycled and reused. Acoustic treatment should be taken to reduce noise produced by ball mill machine.

5. AAC lightweight block production line features light mass, high intensity, heat preservation, sound insulation, etc.

Technical Process Technologies of AAC Block Machine

1. Fixed Point Pouring

Our company uses fixed pouring to save factory space, which is easy for centralized control. Different from stationary pouring, it overcomes the defect that the latter pouring material hardens first and can not be cut. The lightweight block production line is also safe and health to operate.

2. Cutting Technology of AAC Block Machine

Aerated concrete blocks need to be put into the static room for thermal curing so as to accelerate the hardening of brick green body, reduce the body’s static time and improve the production efficiency. Bricks manufactured from AAC lightweight block production line are characterized by uniform density, good pore structure, high strength and good frost resistance. Our AAC blocks machines can produce products in winter. Environmental temperature will not result in the phenomenon of hard middle body but soft surrounding body. We adopt advanced turn-over cutting machines to carry out six surface cutting. The cutting technology features accurate size and beautiful appearance. This lightweight block production line also meets the national standards.

3. Steam Curing Process of AAC Block Machine

There are vacuum and exhaust types optional for customers. It must do procuring before steam curing. During the steam curing process, we adopt rapid raising pressure to reduce the curing time, improve production efficiency, make the product do not crack and acquire high product yield.

- Q: I need komatsu bucket teeth 6600, middle tooth 480, bucket teeth adapters 140 and tooth point 1000. The price in entity store are expensive, and I will wait for a week at least! Are the products online reliable?

- You can, but why? These type on parts are best if sourced locally, especially for heavy equipment parts, the shipping alone will be a fortune!

- Q: What's the difference between an automatic watch and a mechanical watch?

- There is also a "automatic" appearance and ordinary mechanical watches are very similar, but thinner than the ordinary mechanical watches can be very small, it is actually a combination of mechanical and electronic form, it is the power source by button battery or solar battery powered quartz oscillator, this kind of table travel time is very accurate if, generally with the button batteries a year for a change, if the solar cells do not change, now most of the table.

- Q: I'm about 6'2 and really skinny. I want to gain some muscle mass, but I don't have access to very much equipment. I have a treadmill and a rowing machine. What kind of things should I eat, and what would be a good regime for me to use to gain muscle mass. I obviously don't want to loose weight so that's not an issue. How long would it be before I notice any noticeable difference? Thanks in advance.

- Hi there! Well, first things first; you say you are skinny. Gain weight first. You need fat to build muscle. Between 5 and 10 kilos should do the trick. Second; when you have gained weight, start eating lots of proteine, they are the muscle's building blocks. You'll find it in pork, chicken, turkey, shrimps etc. Third; with a tread mill and a rowing machine, you'll have more than enough:) Start wormin up, some people need longer than others, but you should really fil hot and start sweating. So then you could work on your rowing machine, they almost take every muscle in your body after what I have hard. But I also recomend pushups, squats, and situps(also do situps for your back! Very important!). Don't do crunches, they suck! Do one of these, or both, in stead; lie on your back, lift your feet in a 45 degree angle from the floor, and write the numbers from 1 to 10 in the air, and down again. The other one is just like it, but here you rais your feet all the way towards the roof, and use your abs to lift your bum of the floor as high as you can. For your triceps(muscle just beneth your elbow), turn your back to a bed, chair or something, but your hands on the edge, and then sit down on the floor. Use your arms to pull yourself up and down. This should be more than enough to get you started. Remember to dring lots of water and monitor your progress. It will help your motivation. Search the web for more exercises you can do without equipment. How long it will take depends on your genes and how hard you work, so it's difficult to say. Anyway, good luck!

- Q: You could easily make a drink like cool aid with a spoon, water and a packet of flavoring. But when your business for drinks gets really big, like Gatorade, what equipment do they use to produce their drinks?I have a project going on where i have to determine what kind of specalized equipment i will need. I'm making a drink. So what kind of 'specialized equipment' would i need for my business?

- It's all custom made equipment. Do a search for packaging equipment. Good luck*

- Q: Mechanical keyboard?. How much is good?

- SteelSeries 7G was the best, it is good to the keyboard, but this product is worth the price, if the lower 300~400 (original price of around 1000, but in fact most of the more than and 800 machines are better) is recommended; also have to mention the domineering hands support, is comfortable, only 90% people in use after a period of time will get rid of it, because too big and too much in the way of the place

- Q: do you have any book for farm machinery design?

- Yes. okorder . Plenty of books on development of farm machinery.

- Q: Last night I had a scary dream that someone broke into my house and was right outside my bedroom door. In my dream I grabbed my gun out of the nightstand. I had no problem getting the clip in, but when I tried to pull back on it to load a round into the chamber I had a very difficult time and I had to press the butt of the gun against my body so that I could use two hands to cock it back. At that point I knew immediatly I was in a dream and woke up. I always struggle with using firearms in my dreams and I have even pulled the trigger before and nothing happens.This is the same with driving cars. If I get into my car and attempt to drive in a dream I just can't do it. I can't control the vehicle for some reason. It will roll backwards or stall out. What could this mean and has anyone else experienced this?

- Yeah,me,.

- Q: Poll: Could the motor from your mouth operate heavy duty machinery; always running?

- Once it has been jump started and abused it can be pretty heavy duty!

- Q: i m intrested to buy a used copelete uht milk processing machinery with packing machinery prefferably alfa laval and tetra pack capacity of 6000ltr/h to 1000ltr/h

- Go on OKorder.. they sell everything!!!

- Q: Material costs, machinery costs, management costs, labor costs accounted for the proportion of construction projects

- 5, travel expenses, property insurance, 6, 7, 8, engineering maintenance fees, sewage charges, 9, labor protection fees, inspection fees, 10 test, 11, outside the unit management fee, 12, finishing materials and sporadic freight, 13, material shortage and damage

Send your message to us

AAC Block Production Line,excellent, perfact

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords