5050 10 to 30V G4 SMD LED

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 50 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

G4 SMD 5050 LED Lamp

Features of G4 LED Light:

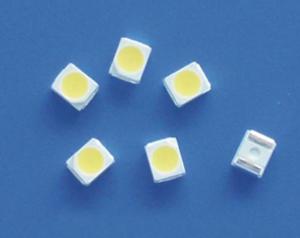

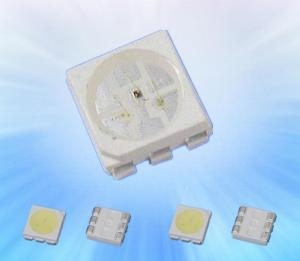

LED Type: 12 pcs Super Bright 5050 SMD LEDs

Volts: 10-30V AC/DC

Watts: 2.5W

Luminous Flux: 180LM

Size: Φ30.3x8mm

Working Temperature: -20~+50°C

Lifespan: 50,000 hours

Color: White, Warm white, Blue, Red and etc

Beam Angle: 120 Degrees

Superbright and low lumen attenuation

Easy installation, maintenance free

No UV or IR

CE, RoHS certificated

Applications of G4 LED Car Light:

G4 LED Light Can be used to convert most 10-30V Halogen G4 fixtures to LED Lighting.

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-15 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: 0603,0805,1206,3020,3528,5050,355 what is the current and voltage of these patch LED? Please give advice!

- The patch LED is also called SMD LED. Its principle of luminescence is to pass the current through the compound semiconductor. Through the combination of the electron and the hole, the excess energy will be released in the form of light to achieve the effect of luminescence.

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- To package with epoxy SMD beads are used in a lot of outdoor display, because the epoxy adhesive with good adhesion to all better PPI support in outdoor use, our high quality and inexpensive epoxy epoxy call for samples

- Q: LED light SMD LED package in what form, trouble you under the guidance of...

- There are 3 types of LED packages: inline LED, piranha LED, and surface mount LED

- Q: What, in what way do I shunt the LED?

- In series, the voltage is 20 times the rated voltage, in parallel, the voltage is rated voltage, but in tandem, a LED is broken, it is not bright, so it is recommended not to use it.

- Q: What is patch SMD-LED?

- Semiconductor wafers consist of two parts, one is P type semiconductor, in which the hole dominates, and the other end is N type semiconductor, which is mainly electronic here. But when the two semiconductors are connected, they form a P-N junction between them. When the current passes through the wire acting on the chip, the electrons are pushed into the P region. In the P region, electrons combine with the hole and then emit energy in the form of photons, which is the principle of LED luminescence. The wavelength of light, that is, the color of light, is determined by the material that forms the P-N junction.

- Q: Is the forward voltage drop of the patch LED too large or too small?

- The pressure drop in the normal range is generally better. The smaller the pressure drop, the lower the power dissipation. The more you save the electricity bill.But not to say that the smaller the better, not in the normal range of low pressure drop products may be defective.In addition, the uniformity of the LED pressure drop is also important.

- Q: Patch LED market conditions

- Patch LED (SMD LED) is mainly used in lighting systems, decoration, electronic equipment, indicators, backlight, monitors and instruments and other fields. The decline in handset and LCD TV production in 2009 could affect the supply expectations for such components.

- Q: What is patch LED?

- Patch element. Very small, no pins, soldered directly to the circuit board. For example, the keyboard lights in a mobile phone are used in this way.

- Q: LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- Mold release agent is a functional substance between the mold and the finished product. The release agent is chemically resistant and is not soluble in contact with the chemical constituents of different resins (especially styrene and amines). Release agent also has heat and stress properties, not easy to decompose or wear; release agent bonded to the mold, and not transferred to the processed parts, without prejudice to painting or other two processing operations. Because of the rapid development of injection molding, extrusion, calendering, molding and laminating, the dosage of mould release agent is greatly improved.

- Q: What does "1210" mean in patch LED?

- At present, most manufacturers of SMD light strip used by 3528 and 5050, and 3535 and 5630 in the majority, there are many of the 3528 and 5050 and 3535, such as patch LED used in automotive lighting.

Send your message to us

5050 10 to 30V G4 SMD LED

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 50 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords