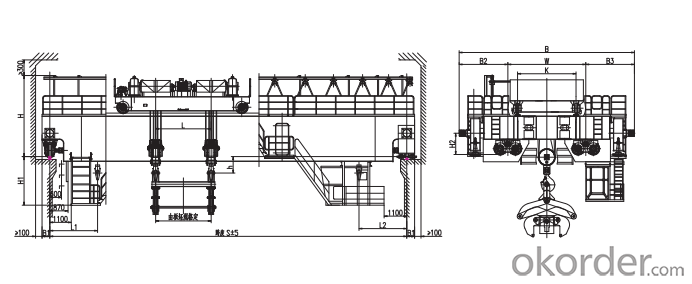

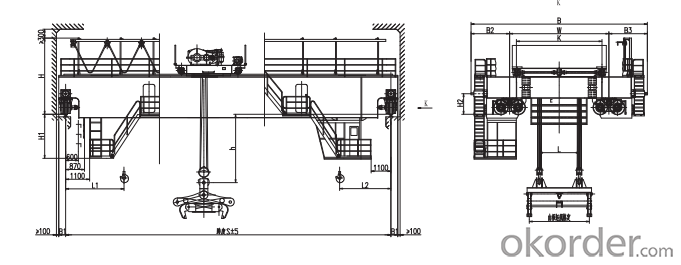

35~65T Tongs Bridge Crane,Anti-sway, PLC Controling System,

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Profile

Tongs bridge crane is widely used in cold and hot rolling mill, used to carry semi-finished and finished steel coil; it is a kind of lifting equipment which has advantages of high working efficiency, strong adaptability, use widely, It belongs to special equipment in metallurgical industry. According to whether is there any auxiliary external force in the process of clamping the material, it can be divided into an external force auxiliary clamp and a gravity clamp. No matter what the size of the goods, if the auxiliary equipment is working properly, the external force auxiliary clamp can grip easily, the utility model has the advantages of simple operation, high production efficiency, adjustable clamping force and so on. Compared with the external auxiliary clamp, the gravity clamp only can depends clamp and material deadweight to clamp the material, the utility model has the advantages of safety, reliability, simple structure, convenient manufacture, low cost, no consumption of power energy, long service life, and so on, so the gravity clamp has been widely applied.

Technical Specification

Clean Weight (m) | 35 | 50 | 65 | |

Span (m) | 27.5 | 37 | 35.5 | |

Lifting Height (m) | 12 | |||

Duty | A7 | |||

Speed (m/min) | Hoisting | 1.2 - 12 | 0.95 - 9.5 | 0.78 - 7.8 |

Crab Traveling | 4.2 - 42 | 3.8 - 38 | 3.8 - 38 | |

Trolley Travelling | 8.5 - 85 | 8 - 80 | 7.5 - 75 | |

Max Wheel Loading (KN) | 375 | 485 | 465 | |

Crane Rail Recommended | QU120 | |||

Power Supply | 3-Phase AC 50Hz 380V | |||

Technical Specification

Clean Weight (m) | 35 | 50 | 65 | |

Span (m) | 27.5 | 37 | 35.5 | |

Lifting Height (m) | 12 | |||

Duty | A7 | |||

Speed (m/min) | Hoisting | 1.2 - 12 | 0.95 - 9.5 | 0.78 - 7.8 |

Crab Traveling | 4.2 - 42 | 3.8 - 38 | 3.8 - 38 | |

Trolley Travelling | 8.5 - 85 | 8 - 80 | 7.5 - 75 | |

Max Wheel Loading (KN) | 375 | 485 | 465 | |

Crane Rail Recommended | QU120 | |||

Power Supply | 3-Phase AC 50Hz 380V | |||

Feature

The clamping device is fetching device of tongs bridge crane, it matched with plurality of working mechanisms of the crane, it can twist flow channel off from mold-ingot car, grip steel ingot, and put steel ingot in soaking pit, then take the after heating steel ingot from soaking pit out and it will be sent to the ingot transport vehicle or directly send to road club. In addition, the tongs bridge crane can also be used to remove the moving ingot cars or to clamp the stove cleaning rake to clean the furnace bottom. when Tongs bridge crane finished the process of procedures aforementioned. because of the operation speed, large vibration, hot ingot be clamped; therefore, all parts of the clamping device should have sufficient strength, it should also have good clamping performance to make sure that the clamping ingot does not fall off the jaw.

Working Principle

The clamping mechanism of the lifting clamp is divided into single rotating clamp plate and double rotating clamp lifting clamp according to the shape of the lifting object; according to the clamping and lifting mode is divided into vertical clamping structure and horizontal clamping structure. Using double rotating clamp lifting to lift the shape symmetry object such as I-beam and steel rail.

For small lifting weight of lifting clamp, the auxiliary clamping device is composed of a tension spring, a fan-shaped lock plate and a handle capable which can control the rotation of the lock plate. The upper and lower limit positions of the lock plate can be self-locking, the upper limit position is locked by the spring eccentric torque, the lower limit position is self locked by the connecting arm curve. For the clamp with larger lifting weights, use hydraulic operated auxiliary clamping device.

Use auxiliary clamping device can make the lifting forceps get better pre-clamping force through the spring force before lifting, In this way, the lifting pliers can maintain sufficient strength in the moment of the lifting and the sudden stop of the rapid ascent and descent.,It still can maintain enough clamping force to prevent the lifting material slipped off from the jaws to cause accidents; It can also be called as a safety device, another function of the utility model is that after the lifting is completed, under the action of the operating handle, the lifting tongs can smoothly open the jaws to remove the goods. The structure of the auxiliary clamping device is relatively simple, but it safety and insurance, also can improve the loading and unloading speed of lifting tongs, makes it an indispensable and important device in the clamp.

Send your message to us

35~65T Tongs Bridge Crane,Anti-sway, PLC Controling System,

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords