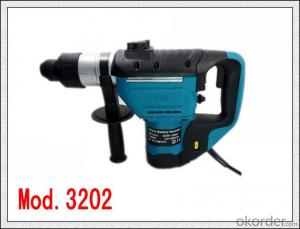

32mm Rotary Hammer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 500Pcs pc

- Supply Capability:

- 10000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

32mm Rotary Hammer

* CN3323

* Rated Voltage: 110-240V~50-60Hz

* Rated Input Power:1100W

* No-Load Speed: 0-800rpm

* Impact Rate: 3200rpm

* Drilling Capacity: 32mm

* 3 Function: Rotation/Rotation&Hammer/Hammer

* Standard Accessories:

3 Sds-Plus Drill Bits 8/10/12x150mm, 2 Chisel Bits 14x250 Mm (Flat&Point), 1 Wrench

* Packing: 45*28*36cm/2pcs, 16/18kgs, 1200pcs/20'cy

* W/CE, GS, EMC, PAHS

Features of 32mm Rotary Hammer

1.Use of magnesium alloy greatly lightens the weight of the tool, which improves working efficiency;

2.Crafty SDS plus chuck bit system enables rotary hammers of relatively lower power to work more efficiently;

3.Through continuous improvements to inner transmitting chain of mechanism, the overall performance is enhanced to ha higher level.

4.Double Anti-Vibration System,Hengyou's Patent, greatly alleviates counterforce to users by the tool. It dramatically relieves fatigue of users, which helps to improve working efficiency;

5.Heat Elimination System,Hengyou's up-to-date design, can dissipate heat through working of the fan. HES largely lowers rotary hammer's temperature, which helps to extend life time of the tool;

6.Patented tool-free grease cover could help users to add grease,even if no wrench is available at hand, which also helps to improve working efficiency;

7.Design of variable speed provides users with more choices when working under different environments;

8.Auto-stop carbon brush with high quality greatly extends life time of the motor part, which not only saves maintenance cost, but also create more values for users;

9.Main handle and auxiliary handle have been covered by soft grip makes users feel more confortable when working;

10.Brand new designed function switch would help you to shift functions more quickly labor-saving.

- Q: How are hand powered tools classified into class I, class II, class III?

- Nowadays, class I hand held power tools are virtually discontinued. The class II hand-held electric tools are widely used. Class II hand held electric tools are generally used on special occasions such as wet environments, metal containers, etc..

- Q: What safety problems should we pay attention to when using electric drills or hand-held power tools?

- The motor inlet shall be provided with a ground or zero connection device.(4) wearing shoes must be worn while wearing protective gloves such as insulating gloves.(5) each use of tools must be strictly checked.

- Q: What's the role of carbon brushes in electric tools?

- In addition to induction type AC asynchronous motors, there is no outside. Other motors are provided, as long as the rotor has a reversing ring.The principle of electric power generation is that a magnetic field cuts a wire to produce an electric current in the wire. The generator cuts the wires by rotating the magnetic field. A rotating magnetic field is a rotor, and the wire to be cut is a stator.

- Q: What other tools are there for the furniture except the pistol hole?

- It is mainly used in construction, decoration, furniture industry, opening for objects or objects in the past, also known as hammer in some industries.Well, there are more drilling tools on the market now.

- Q: Is BOSCH's power tools good or MAKITA's power tools?

- MAKITA electric tool features:The utility model has the advantages of small noise, strong power, good performance, long service life, light body, strong and durable, easy operation and convenient repair. The utility model is the necessary high-quality product for professional personnel or amateur DIY personnel.

- Q: What power tools are used as cage birds?

- An electric drill or a small bench drill, drill speed is the best because of the speed change drill, drill hole spacing and easy consumption. If you want to do with special accessories can also change the distribution of wood milling, milling machine, special safety and easy to do.

- Q: What kind of material does the power tool case have?

- In 1895, the German overtone produced the world's first direct current drill. The outer shell is made of cast iron and can drill holes in the steel plate 4mm. Then there was a three-phase power frequency (50Hz) electric drill, but the motor speed failed to break through the 3000r/min. In 1914, there was a single-phase electric motor driven by a series of exciting motors, and the motor speed was over 10000r/min. In 1927, the power supply frequency of intermediate frequency electric tool 150~200Hz, it not only has the advantages of high speed single-phase series motor, and has the advantages of simple structure, reliable three-phase motor, but because the need if current supply is limited.

- Q: What's the difference between a flashlight and an electric screwdriver?

- Equipped with torque regulation and restriction mechanism, electric tool for screwing and unscrewing screws, the electric tool, mainly used for assembly line. Is one of the necessary tools for most manufacturing enterprises.

- Q: What devices must be available for all hand held electric tools?

- Anti leakage, splash prevention, anti movement, anti overheating

- Q: How to detect the rotor of power tools?

- Rotor spark. 1) the carbon brush and commutator rotor, no free contact. 2) the connection spring on the carbon brush nest is burned, and the person who is burned is not able to connect normally. A vicious circle, sparks plus sparks. Machine failure will also occur.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1998 |

| Annual Output Value | US$ 30 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai; Ningbo |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | About 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average; Low |

Send your message to us

32mm Rotary Hammer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 500Pcs pc

- Supply Capability:

- 10000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches