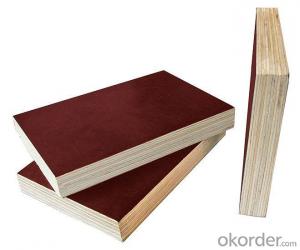

3/4 Inch Door Skin Poplar Core Plywood in Different Sizes

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Door Skin:

Product Name: Slice Cherry plywood

Face/Back: Cherry

Core: Poplar,Hardwood,Pine,Birch,Eucalyptus,Combi etc

Size:1220×2440mm,1250×2500mm,1220×2150mm,1830×3660mm etc

Thickness: 2.7-30MM

Thickness Tolerance: +-0.1mm~0.3mm <=6mm< +-0.3mm~0.5mm >6mm

Glue:WBP/MR/MELAMINE/E0/E1/E2

Grade:BB/BB BB/CC CC/CC etc

Moisture: 8-14%

Process of Engineered Veneer Wood:

Log Selection

EV is generally produced from Chinese Poplar logs, grown locally either by local co-operatives,

or in registered plantation areas. The light natural colour and soft grain definition of Poplar makes it wellsuited to the production of EV. The process of converting timber into EV starts with the selection of logs, following which they are bought to the mill for processing. The timber is trimmed, sawn to length and debarked. The logs are now ready to be peeled.

Peeling of the Logs

The logs are mounted onto a giant lathe. Within minutes the logs are peeled into rotary veneers. This is achieved by pressing a rotating log towards a large blade, thinly peeling a continuous sheet of veneer off the log. The veneer is dried, stacked and then graded. It is now ready to be dyed.

Drying

EV veneers can be dryed to a consistent colour to suit the market requirement. The raw veneer leaves are stacked into a stainless steel cage. Once completely loaded, the stainless steel cage is immersed into a pressurized, heated vat that is filled with water soluble dry. This system ensures that each leaf is given the correct amount of time to allow the dry to completely penetrate each individual leaf of veneer. Once the desired colour has been achieved, the leaves are unloaded from the vat, dried and given a final inspection before going to the gluing stage.

Gluing

The gluing process is critical for the performance of the finished product. A layer of glue goes between each leaf of veneer, to bond the leave of veneer together. Once the stack has been laid up it is then put into a high pressure press to bond the leaves together, creating a large rectangular block.

Slicing of the Block

The block in now ready to be sliced into veneer leaves. Once the block has been produced, it is turned through 90 degrees, to present the end grain, then mounted to the slicing unit. The blade now runs across the end grain of the block, slicing thickness controlled leaves of veneer. The veneer leaves that are produced are approximately 0.4mm thick, and in 2440 x 1220 format. The veneer is now ready to be used as face veneer for Eucalyptus and Poplar core plywood products.

Packing Details of Door Skin:

MOQ: 40HQ

Packing Details: 20GP 8pallets/21M3

40GP 16pallets/42M3

40HC 18pallets/53M3

Payment Terms: 30%T/T in advance,70%L/C

Delivery Time: 15 to 20 days after receiving 30%T/T down payments

Technical Data of Door Skin:

Grade Description | AA | A | B | C | D | E | ||

Sapwood | No | No | Slight color difference | Slight color difference | Yes | Yes | ||

Heartwood | No | No | No | Slight color difference | Yes | Yes | ||

Color Streaks or Spots | Slight | Slight | Slight color difference | Slight color difference | Yes | Yes | ||

Color Variation | No | No | Slight | Slight | Yes | Yes | ||

Sharp Color Contrasts at Joints | No | No | No | Slight | Yes | Yes | ||

Type of Matching Book Matched Slip Matched Pleasing Matched |

Yes Specify -- |

Yes) Specify -- |

Specify Specify Yes |

-- -- -- |

-- -- -- |

-- -- -- | ||

Nominal Minimum Plain-S Width of Face Quarter 1/4 Componentsa Rotary | 152 mm 76 mm 152 mm | 127 mm 76 mm 127 mm | 76 mm 76 mm 102 mm | No Limit | ||||

Small Conspicuous Burls & Pin Knots-Combined Avg. Numbe | 2 per 1m2

| 4 per 1m2

| 6 per 1m2

| No Limit | ||||

Conspicuous Burls-Max. Size | 6.4 mm | 9.5 mm | 12.7 mm | No Limit | ||||

Conspicuous Pin Knots Avg. Number Max. Size: Dark Part Total |

No |

No |

3 per 3 m2 3.2 mm 6.4 mm | No Limit | ||||

Scattered Sound and Repaired Knots-Combined Avg. Number Max. Size-Sound Max. Size-Repaired Avg. No.-Repaired | No | No |

4 per 3 m2 9.5 mm 3.2mm 4 per 3 m2

|

3 per 1 m2 1 2.7 mm 12.7 mm 4 per 3 m2 |

4 per 1 m2 25.4 mm 19 mm 2 per 1 m2 |

No Limit 38 mm 25.4 mm 1 m2 | ||

Mineral Streaks | No; Maple, Slight | Slight

| Slight

| Slight | Yes | Yes | ||

Bark Pockets | No | No | Few to 3.2mmx25.4mm | Few to 6.4mmx50.8mm |

6.4mmx50.8mm |

Yes | ||

Worm Tracks | No | No | Slight | Slight | Yes | Yes | ||

Vine Marks | Slight | Slight | Slight | Yes | Yes | Yes | ||

Cross Bars | Slight

| Slight | Yes | Yes | Yes | Yes | ||

- Q: National standards for decorative veneer veneer plywood performance requirements

- Its physical and mechanical performance indicators are: moisture content, surface bonding strength, impregnation stripping

- Q: The difference between the multilayer board and the plywood is as follows

- Also available for aircraft, ships, trains, cars, construction and packaging board and other materials.

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: What are the further processing of plywood?

- Direct printing plywood Direct print plywood is printed directly on the plywood surface with simulated wood grain or other patterns.

- Q: What types of plywood can be divided into?

- Class I (NQF) - weather resistant, resistant to boiling plywood Class II (Ns) - Water resistant plywood.

- Q: What are the processing defects of plywood?

- Edge defects at the edges of the panel due to sanding, sawing or collision caused by the corner defects.

- Q: What are the defects of the plywood?

- partially intergrown knOts surrounded by the surrounding wood part of the length of its cross-section around the length of more than 1/4 to 3/4, texture Kuang hard.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- It is usually made of odd-numbered veneers and The fibers of the adjacent veneers are perpendicularly bonded to each other

- Q: What is the plywood made of wood?

- Commonly used plywood type plywood, penta and so on. Plywood can improve timber utilization and is a major way to save wood

- Q: Does plywood contain formaldehyde?

- 12 cm plywood is usually 3-4 layers of natural wood chips "glue" together, each layer of double-sided roller plastic hot forming, the whole board about 3 kg of glue

Send your message to us

3/4 Inch Door Skin Poplar Core Plywood in Different Sizes

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords