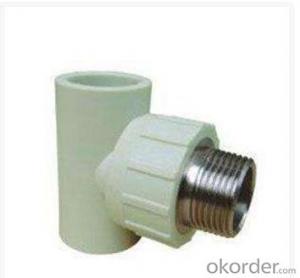

1 4 Plastic Pipe Fittings - 2024 New Plastic Tee for Industrial Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Product

1. It is used in industrial fields, agriculture and garden irrigation

2. Beauty appearance.

3. Thermal insulation and energy saving.

4. Easy installation

5. Excellent heat resistance and pressure resistance

6. Affordable price

Size

Size | ITEM.No. | D | d | L | B | Qty/ctn | Weight/ctn(kg) |

20 | DSC901 | 28.4 | 19.2 | 15.5 | 26 | 540 | 12.12 |

25 | DSC902 | 34.5 | 24.1 | 17.5 | 30 | 300 | 11.17 |

32 | DSC903 | 43.6 | 31 | 19.5 | 35.5 | 180 | 11.64 |

Specification

Products name | Plastic Tee |

Material | Plastic |

Field of Application | Water |

Work temperature | -10℃-110℃ |

Packing | PE bag and carton |

Function | Kitchen, home, commercial, garden and general |

Place of origin | Hebei China(mainland) |

Brand | CMAX |

Certificate | CE,ISO9001 |

Product Applications:

1.Distribution for cool and hot water

2.Duct for drinkable water system

3.Pipes for kinds of high-temperature and low-temperature heating system

4.Pipes for heating and coolling settings in solar energy system

5.Connecting pipe for air conditioners

Product Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Main Product Features:

1. Large drum hub to maximize cable life

2. Self-activating automatic brake hold the load securely when crank handle is released

3. With cable or strap

4. Safety guard cover available

5. Top quality with competitive price

6. Widely used in the double beam bridge crane and gantry crane

7. Easy to install and high quality

8. Compact structure and reasonable design

9. Could be mounted on t he ground or wall!

10. Double drum!!

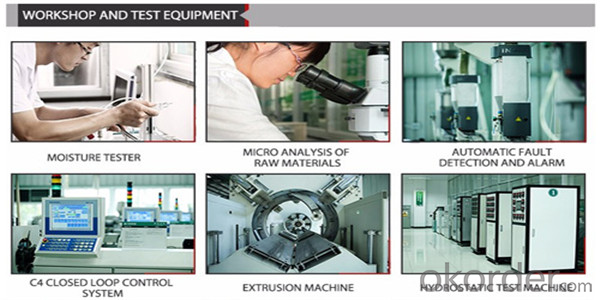

Company Profile

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

Q4:What Is Our Normal Payments Terms?

A4:Our normal payment terms now is: T/T, L/C or western union,paypal

- Q: Are plastic pipe fittings resistant to scaling and buildup?

- Yes, plastic pipe fittings are generally resistant to scaling and buildup.

- Q: Can plastic pipe fittings be used for gas lines?

- No, plastic pipe fittings should not be used for gas lines. Gas lines require materials that are specifically designed to handle the high pressure and potential hazards associated with gas, such as corrosion and leaks. Metal pipe fittings, such as those made of steel or brass, are typically recommended for gas line installations to ensure safety and compliance with relevant building codes and regulations.

- Q: Are plastic pipe fittings resistant to solvents?

- Yes, plastic pipe fittings are generally resistant to solvents. Their resistance depends on the specific type of plastic used, but many plastic pipe fittings are designed and manufactured to withstand exposure to a wide range of solvents without degradation or damage. It is important to consult the manufacturer's specifications or guidelines to ensure compatibility with specific solvents.

- Q: Are plastic pipe fittings resistant to freezing temperatures?

- Yes, plastic pipe fittings are generally resistant to freezing temperatures.

- Q: Can plastic pipe fittings be used in compressed air systems?

- No, plastic pipe fittings should not be used in compressed air systems as they are not designed to withstand the high pressure and can pose safety risks. Metal fittings, such as brass or stainless steel, should be used instead.

- Q: Can plastic pipe fittings be used for conveying food products?

- No, plastic pipe fittings should not be used for conveying food products. It is recommended to use food-grade materials such as stainless steel or food-grade plastic fittings that are specifically designed and approved for contact with food. Plastic pipe fittings may contain chemicals or additives that could leach into the food, posing a potential health risk.

- Q: Are plastic pipe fittings resistant to leaks?

- Yes, plastic pipe fittings are generally resistant to leaks due to their tight and secure connections.

- Q: Are plastic pipe fittings resistant to fungal and bacterial growth?

- Yes, plastic pipe fittings are generally resistant to fungal and bacterial growth. Plastic materials such as PVC (polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride) used in pipe fittings are inherently resistant to the growth of fungi and bacteria. Additionally, plastic fittings are non-porous and provide a smooth surface that discourages the accumulation of organic matter, making them less susceptible to microbial growth compared to other materials like metal. However, it is important to note that proper maintenance, regular cleaning, and adherence to recommended usage guidelines are crucial to maintain the microbial resistance of plastic pipe fittings.

- Q: Can plastic pipe fittings be used in solar water heating systems?

- Yes, plastic pipe fittings can be used in solar water heating systems. Plastic fittings are commonly used in these systems due to their durability, resistance to corrosion, and ease of installation.

- Q: Can plastic pipe fittings be used in food processing systems?

- Yes, plastic pipe fittings can be used in food processing systems. They are often made from food-grade materials such as PVC, CPVC, or polypropylene, which are resistant to corrosion, chemicals, and bacteria growth. These fittings are designed to meet strict sanitation and safety standards, making them suitable for use in food processing applications.

Send your message to us

1 4 Plastic Pipe Fittings - 2024 New Plastic Tee for Industrial Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords