2015 Hot Sale Waterproof Masking Tape Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 30000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

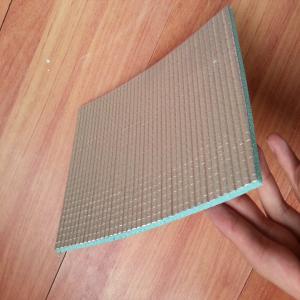

Describtion of 2015 Hot Sale Waterproof Masking Tape Made in China

Masking tape is using crepe paper as backing material and coated with natural rubber adhesive

Standard size: 24mm*30, 48mm*30m,0.99m*1800m,1.22m*1800, etc.

Application : widely used for painting masking, furniture, shoe material production, auotmobile painting.

| Item No. | Thickness (micron) | Initial Tack | Holding Power (hour) | Tensile Strength (N/cm) |

| Adhero1-1 | 160 | 10# | 2 | 16 |

| Adhero1-2 | 150 | 8# | 3 | 16 |

| Adhero1-3 | 150 | 10# | 3 | 16 |

| Adhero1-4 | 160 | 8# | 4 | 26 |

| Adhero1-5 | 150 | 10# | 15 | 30 |

| Adhero1-6 | 140 | 10# | 10 | 26 |

Pakaging & Shiping 2015 Hot Sale Waterproof Masking Tape Made in China

Packaging Detail | standard packing / genuine packing / as per customer's packing instruction |

Delivery Detail | 15 ~ 30 days after receiving the deposit |

Our service of 2015 Hot Sale Waterproof Masking Tape Made in China

1. We have good and professional team

2. We accept any drawings or your samples to develop new product

3. Any small problems will be solved at the most prompt time

4. We always offer relative technical support, quick response, all your inquire will replied within 24 hours

Company Information

CNBM International Corp., established in 2004, is the business entity fortrade and logistics of CNBM Group, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council of People’s Republic of China.

Adhero Technology is the adhesive tape division of CNBM International Corporation. Over the past decade we have been developed into a leading manufacturer of adhesive tapes in China. We mainly supply various kinds of adhesive tapes as BOPP packing tape, cloth duct tape, double sided taoes, PVC tapes, Aluminum foil tape etc.

FAQ: What are your company advantages?

Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

5. CNBM have export to more than 100 countries with 20 year's experience

- Q: How do automotive plastic products contribute to overall vehicle efficiency?

- Automotive plastic products contribute to overall vehicle efficiency in several ways. Firstly, plastic components are lighter than metal counterparts, reducing the overall weight of the vehicle and improving fuel efficiency. Secondly, plastic parts are often designed with aerodynamics in mind, reducing drag and enhancing the vehicle's performance. Additionally, plastic materials offer better insulation properties, reducing the need for energy-consuming heating or cooling systems. Lastly, plastics can be molded into complex shapes, allowing for more efficient and streamlined designs, ultimately improving the vehicle's overall efficiency.

- Q: How do I remove the wax on plastic?

- Use the hair dryer to dissolve the solid wax, and then quickly use the toilet paper and other absorbent cotton cloth to dry

- Q: How do automotive plastic products contribute to improved resistance to abrasion?

- Automotive plastic products contribute to improved resistance to abrasion due to their inherent properties such as durability, flexibility, and low friction coefficient. These properties allow them to withstand the wear and tear caused by friction, impacts, and environmental factors, thus providing a protective barrier for the underlying components. Additionally, automotive plastics can be engineered with additives and coatings that enhance their resistance to abrasion, further increasing their lifespan and performance in demanding conditions.

- Q: How do automotive plastic products contribute to improved resistance to engine oil and lubricants?

- Automotive plastic products contribute to improved resistance to engine oil and lubricants through their chemical composition and design. These products are specifically engineered to be resistant to the corrosive and degrading effects of oil and lubricants, which helps maintain their structural integrity and functionality over time. Additionally, the use of plastic materials in automotive components reduces the risk of oil leaks and contamination, ensuring efficient lubrication and overall engine performance.

- Q: What are the considerations for using plastic in automotive chassis and body reinforcement systems?

- There are several considerations to keep in mind when using plastic in automotive chassis and body reinforcement systems. First and foremost, the strength and durability of the plastic material must be thoroughly evaluated to ensure it can withstand the various stresses and forces experienced by the vehicle. Additionally, the weight of the plastic component should be carefully considered, as it directly affects the overall weight and fuel efficiency of the vehicle. The cost of manufacturing and implementing plastic parts should also be taken into account, as it can impact the affordability and market competitiveness of the vehicle. Lastly, the environmental impact of using plastic should be considered, including its recyclability and potential for reducing carbon emissions.

- Q: How do automotive plastic products contribute to vehicle manufacturing efficiency?

- Automotive plastic products contribute to vehicle manufacturing efficiency by offering lightweight and durable alternatives to traditional materials. Their use reduces the overall weight of the vehicle, improving fuel efficiency and reducing emissions. Additionally, plastic components can be easily molded, allowing for quicker and more cost-effective production processes. Plastic parts also provide enhanced design flexibility, enabling automakers to create innovative shapes and designs that optimize aerodynamics and space utilization. Overall, automotive plastic products play a crucial role in streamlining manufacturing operations and enhancing the overall efficiency of vehicle production.

- Q: Can automotive plastic products withstand extreme temperatures?

- Yes, automotive plastic products are designed to withstand extreme temperatures. They are engineered with heat-resistant materials that can endure high temperatures without melting or deforming, making them suitable for use in various automotive applications.

- Q: What are some examples of automotive plastic products used in police vehicles?

- Some examples of automotive plastic products used in police vehicles include dashboards, center consoles, door panels, seat covers, bumper covers, and interior trim pieces.

- Q: The mud marks on the plastic parts how to clean the car

- Wash it with water directly.Then wipe it a little bit, which will protect the car's cleanliness and reduce the damage to the parts.

- Q: What are some examples of automotive plastic products used in recreational vehicles?

- Some examples of automotive plastic products used in recreational vehicles include interior trim panels, dashboard components, seat parts, storage compartments, exterior body panels, fender flares, and wheel covers.

Send your message to us

2015 Hot Sale Waterproof Masking Tape Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 roll

- Supply Capability:

- 30000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches