18mm PPR Coupling Fittings of Industrial Application 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Products

Place of Origin: Henan, China (Mainland)

Model Number: PE100

Material: PE

Specification: DN 20-mm~DN1200mm

Length: According to customer requirement

Thickness: SDR11/13.6/17

Standard: ISO

Color: many colors

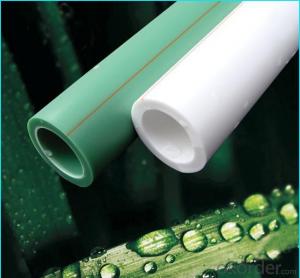

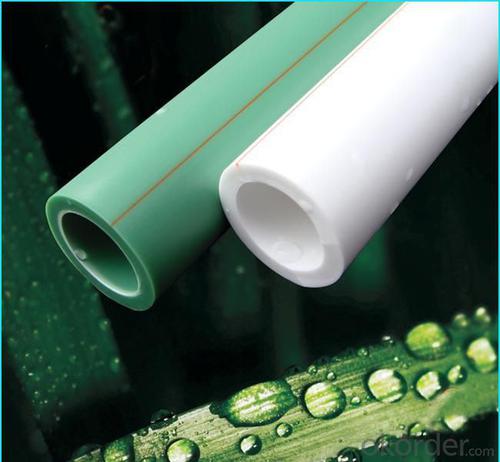

Product name: Plastic Pipe

Application: house and garden

Usage: Family Decoration Industry

Certification: ISO Certificate

Feature: Lightweight

Size: Customized Size

Type: Round Pipe

Name: HDPE Plastic Pipe

Connection: Butt Fusion

Size

Product name | Size | Weight | Pack |

Equal tee

| (Gram/m) | (m/pack) | |

T16 | 12.5 | 1300 | |

T20 | 19.4 | 800 | |

T25 | 30.5 | 450 | |

T32 | 48.2 | 260 | |

T40 | 90.8 | 150 | |

T50 | 142.5 | 106 | |

T63 | 275.3 | 54 | |

T75 | 515.0 | 30 | |

T90 | 712.0 | 18 | |

T110 | 1082.0 | 12 | |

T125 | 1544.0 | 8 | |

T160 | 2531.0 | 4 |

Products Show

Introduction of Company

CNBM practices the parent-subsidiary management system, and is one of those wholly state-owned enterprises carrying out the pilot trial of Board of Directors system and innovation system. As the strategic center, decision center, resources center, and policy & culture center, our Group exercises its right as a contributor. Whereas, our sub-groups functioning as business platforms, are mandated to construct the profit center based on their core competences to enlarge brand awareness and increase market share.

FAQ

Q: What you offer?

A: Any kinds of goods you need, just send us the request, we will reply you back with the details very soon.

Q: Product quality and delivery time?

A: Normally 7-15 days after the order confirmed, we will collect the goods and inspect each of the items and send you the inspection photos for you to confirm.

Q: What's the regular shipping port?

A: Tianjin, Shanghai.

Q: What's your payment?

A: T/T,L/C,D/P,D/A

- Q: Can plastic pipe fittings be used for both hot and cold water applications?

- Yes, plastic pipe fittings can be used for both hot and cold water applications. They are designed to withstand a wide range of temperatures and are commonly used in plumbing systems for residential and commercial buildings. However, it's important to ensure that the plastic fittings are specifically labeled and certified for hot water use to ensure their durability and safety.

- Q: Are plastic pipe fittings suitable for use in pharmaceutical laboratories?

- No, plastic pipe fittings are not suitable for use in pharmaceutical laboratories.

- Q: Can plastic pipe fittings be used for fuel systems?

- No, plastic pipe fittings are not recommended for use in fuel systems.

- Q: Are the elbow and three - pipe fittings installed in the water supply and drainage pipes included?

- Indoor and outdoor plastic water supply pipe (hot melt connection) project, the pipeline joint parts are the same way of plastic pipe is connected with the pipeline, including various types of steel (copper) plastic conversion parts, such as other materials fee, the remaining unchanged.

- Q: Can plastic pipe fittings be used for water desalination systems?

- Yes, plastic pipe fittings can be used for water desalination systems. Plastic pipe fittings are often made from materials that are resistant to corrosion and can withstand high pressure, making them suitable for use in water desalination systems. Additionally, plastic fittings are lightweight, easy to install, and cost-effective, making them a popular choice for such applications.

- Q: Can plastic pipe fittings be used in fire extinguisher systems?

- No, plastic pipe fittings should not be used in fire extinguisher systems as they are not suitable for high-temperature environments and can potentially melt or fail under fire conditions. Metal fittings are recommended for these systems to ensure safety and reliability.

- Q: What is the average lifespan of plastic pipe fittings?

- The average lifespan of plastic pipe fittings can vary depending on factors such as the type of plastic used, the conditions they are exposed to, and the quality of installation. However, in general, plastic pipe fittings can last anywhere from 20 to 50 years or more.

- Q: Can plastic pipe fittings be used in agricultural applications?

- Yes, plastic pipe fittings can be used in agricultural applications. They are commonly used for irrigation systems, water supply lines, and drainage systems in agricultural settings. Plastic fittings are durable, resistant to corrosion, and can withstand harsh environmental conditions, making them suitable for various agricultural applications.

- Q: Are plastic pipe fittings resistant to hydrochloric acid?

- No, plastic pipe fittings are generally not resistant to hydrochloric acid as it can corrode or degrade the material.

- Q: Are plastic pipe fittings resistant to scale and sediment buildup?

- Yes, plastic pipe fittings are generally resistant to scale and sediment buildup. Unlike metal fittings, plastic fittings do not corrode or rust, which helps prevent the accumulation of scale and sediment. Additionally, the smooth interior surface of plastic pipes and fittings makes it difficult for scale and sediment to adhere and accumulate.

Send your message to us

18mm PPR Coupling Fittings of Industrial Application 2024

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords