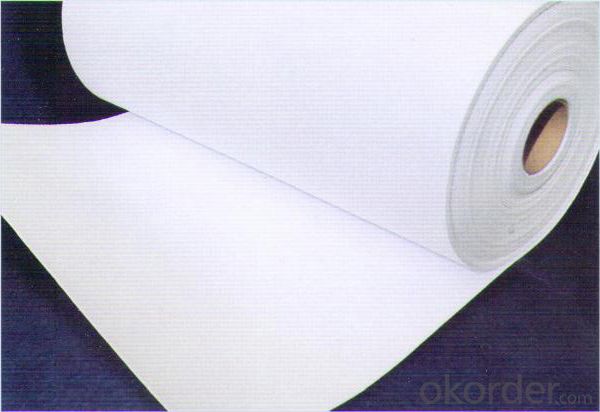

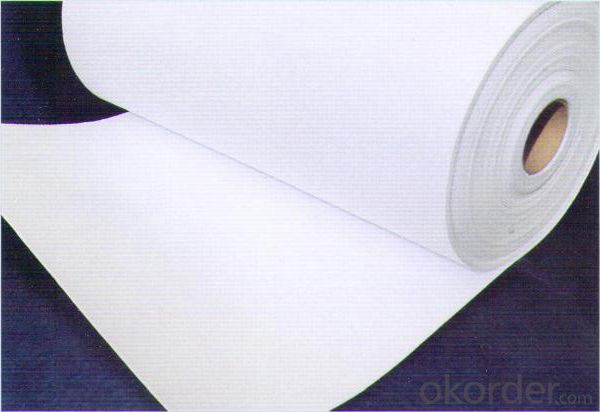

1260 Rock Wool Naiti Refractory Ceramic Fiber Paper for Fireplace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 roll

- Supply Capability:

- 1000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

NATI Ceramic Fiber Paper is formed from ceramic fiber mixed along with binders, with high thermal capacity, excellent resistance to corrosion, good thermal resistance to shock, low thermal conductivity, good electric insulation, and good springiness. It can be used for thermal insulation, sealing, electric insulation, sound absorption, filtration etc instead of asbestos products as a kind of advanced light refractory material.

Characteristics

*Asbestos free

*Long fiber, less shot

*High strength, high tensile strength

*Resistance to erosion

*Low thermal conductivity

*High electric insulation

*Easy to cut, and seal

Typical Application

*High temperature insulating gasket

*Insulation for electric apparatus

*Materials for high temperature filtration

*Soundproof materials of auto

*Exhausting and thermal materials for exhaust pipe

*Sealing material

*Cut for all kinds of gaskets and sealing

Physical & Chemical Data

Description | 1000 NATI Ceramic Fiber Paper | 1260 NATI Ceramic Fiber Paper | 1400 NATI Ceramic Fiber Paper |

Classification temperature (℃) | 1000 | 1260 | 1400 |

Density (Kg/m3 ) | 210 | 210 | 210 |

Linear shrinkage ( % ) (℃*24 h ) | 3.5 (850) | 3.0 (1100) | 3.2(1200) |

Rupture strength (MPa) | 0.5 | 0.65 | 0.70 |

Organic content (%) | 10 | 8 | 6 |

Average 400℃ | 0.06 | 0.07 | |

Average 600℃ | 0.08 | 0.09 | 0.08 |

Average 800℃ | 0.12 | 0.12 | 0.12 |

Average 800℃ | 0.17 | 0.16 | |

Chemical composition ( post-burnt ): | |||

Al2O3 | 42 | 46 | 35 |

SiO2 | 54 | 50 | 44 |

ZrO2 | 15.5 |

Dimension

40000×600×0.5, 1mm 20000×600×2mm 10000×600×3,4,5,6mm

- Q: What does the rock wool board look like?

- Rock wool board to basalt as a material, after high temperature melting processing into artificial inorganic fibers, with a light weight, thermal conductivity, heat absorption, non-flammable characteristics

- Q: What role does dolomite play in rock wool products?

- Pu hard foam layer can be firmly bonded with the base layer, the adhesive strength can exceed the tear strength of the foam itself, so Pu hard foam and the formation of the base layer, easy to delamination, to avoid the water along the interlayer

- Q: Rock wool products are divided into several categories

- Rock wool with a light weight, non-combustible, small thermal conductivity, sound absorption performance, good chemical stability and so on

- Q: How to judge the quality of rock wool

- How to judge the quality of rock wool

- Q: The difference between rock wool and rock wool

- Flexible, medium strength rock wool board: for building walls / roof insulation, fire, sound, such as curtain wall, wall partitions, elevator wells, etc

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- No, rock wool is ore blown wire, aluminum silicate is coke gem

- Q: Rock wool insulation material fire rating is how much

- Rock wool insulation material fire rating is how much

- Q: Rock wool board is inorganic composite insulation material

- Insulation material A-level fire is organic meet the inorganic meet resolutely

Send your message to us

1260 Rock Wool Naiti Refractory Ceramic Fiber Paper for Fireplace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 roll

- Supply Capability:

- 1000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords