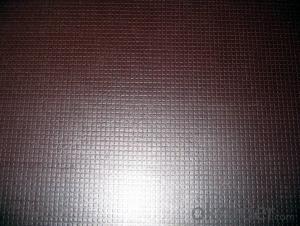

1/2 Inch Plywood - Full Poplar/Hardwood/Pine Packing Grade LVL

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full poplar/hardwood/pine packing grade LVL

| size: | Max:120x1200x10000mm |

| Materials: | pine/poplar/hardwood |

| Glue: | WBP Phenolic glue/MR/melamine |

| Density: | 520-700kg/m3 |

| M.C.: | 12-15% |

| Machining: | edge rounded/beveled/chamfered/sanded |

| Quantity: | 18pallets/40HQ |

| delivery time | 15days |

Certificate: AS-1577 Standard/SGS Certificate.OSHA

Bonding strength:> 0.7mPa

Length Tolerence :+/-1mm

Formaldehyde Emission :≤ 1.5mg/l

* Laminated veneer lumber (LVL) is a structural product manufactured from thin peeled veneers of wood glued with a durable adhesive with the grain running parallel to the main axis of the member.

* Panels of LVL are cut into structural members which have high strength and stiffness.

* LVL is suited to structural applications such as beams, rafters and columns in a wide range of buildings including houses, commercial, industrial and rural structures. Some special LVL has a small number of veneers laid perpendicularly (cross banded).

* High strength-to-weight ratio - more than 40 stronger than solid sawn products

* High design values for bending, stiffness and shear strength

* Resists shrinking, warping, splitting and checking

* No defects to cut out and less waste on the job

* Ordinary nail assembly - installs as easily as ordinary lumber

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- moisture content. Between 12 and 14% (according to Chinese national standards, Ⅰ, Ⅱ plywood absolute moisture content of not more than 13%;

- Q: Now what is the market for plywood development?

- has also been greatly improved in the international market more and more competitive. China is not only a large veneer export, or the world's largest plywood producer.

- Q: What is the best way to fix multi-layer plywood?

- The usual length and width specifications are: 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on

- Q: What is the type of plywood editing?

- decorative plywood (for construction, furniture, vehicles and ship decoration materials), the general use of plywood (for packaging, bedding and other uses)

- Q: The Preparation of plywood ingredients

- central layer central ply plywood center layer, the other layers are symmetrically arranged on both sides of it.

- Q: What are the defects of the plywood?

- The intergrown knots are formed by the tree's live technique. Knots and the surrounding wood close together or with the surrounding wood part of the length of its cross-section than the length of 3/4, hard texture, normal structure

- Q: What are the advantages and disadvantages of plywood?

- and then made of adhesive glue from the three or more layers of plate-like material

- Q: For the plywood environmental advice?

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: The basic principle of plywood

- In order to improve the characteristics of natural wood anisotropy, so that the characteristics of plywood consistent, stable shape, the general plywood in the structure must meet two basic principles

Send your message to us

1/2 Inch Plywood - Full Poplar/Hardwood/Pine Packing Grade LVL

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords