1 2 in Particle Board Plain Honey Comb Particle Board for Door Core

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Product:

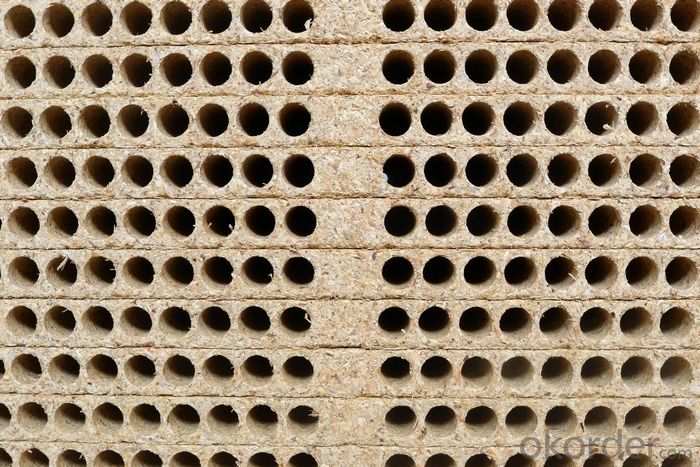

Plain Honey Comb Particle Board For Door Core

Advantages & application:

The door core with cross-drilled hole made by extrusion forming of large pressing machine has the following advantages compared with the door core with vertical hole.

1. All products are made by extrusion forming of large pressing machine. The holes are horizontal and the width of the pressing machine reaches 2040.

2. The holes are horizontal, no need of cutting during construction, improve efficiency and impact resistance.

3. It can be customized, accurate size, cut-free and loss-free.

4. Lock pinhole (There is a pinhole in the center of the door core, no need of cutting, a lock rod is placed, improve efficiency and impact resistance).

5.Eco-friendly, thermal insulation, sound insulation, light weight, impact resistance, stable dimension.

Specification:

Material: poplar, pine

Glue: E1

Width: 800-1400mm

Thickness: 24mm, 28mm, 30mm, 33mm, 34mm, 35mm, 38mm,

Length: 2090mm,2100mm

Bore Diameter: 18-27mm

Moisture Content: 7-10% Storage Tray, low humidity

Certificate: ISO 9001,CE

Photos:

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q: Today's demand for wood-based panel products

- coupled with the "Eleventh Five-Year" period of China's urban public facilities investment in fixed assets more than one trillion yuan

- Q: According to the surface conditions:

- decorative particleboard: impregnated paper finishes particleboard; decorative laminate veneer particle board; veneer veneer particleboard; surface coated particleboard; PVC veneer board and so on.

- Q: The Particleboard quality identification editor

- including North China, northwest, northeast plate moisture content is generally controlled at 6-8% is appropriate; the southern region,

- Q: What is the modeling technology department?

- mainly urea-formaldehyde resin, the product surface with a single board or resin impregnated paper paste, a molding.

- Q: A simple introduction to particleboard

- sound and sound insulation is also very good. But it also has its inherent shortcomings, because the edge of rough, easy to moisture

- Q: Particleboard in the production process of environmental performance

- if the smell is large or have tears, indicating that the release of formaldehyde in the particleboard may be higher.

- Q: Particleboard production process requires proper hot pressing pressure

- Box molding method is a special press pressure, a pressure made of products for the manufacture of crates.

- Q: From the appearance point of view

- the length is generally 5-10MM length is appropriate, too long structure loose, too short anti-deformation of the poor, the so-called static bending strength is not compliance;

- Q: How does the particleboard work?

- Hot pressing is a key step in the production of particleboard, which acts to cure the slab in the slab and consolidate the loose slab into a sheet of the specified thickness

- Q: What types of particleboard can be divided into?

- For special use of the particleboard also according to different purposes, respectively, consider the electrical, acoustic, thermal and corrosion, fire, flame retardant and other properties.

Send your message to us

1 2 in Particle Board Plain Honey Comb Particle Board for Door Core

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords