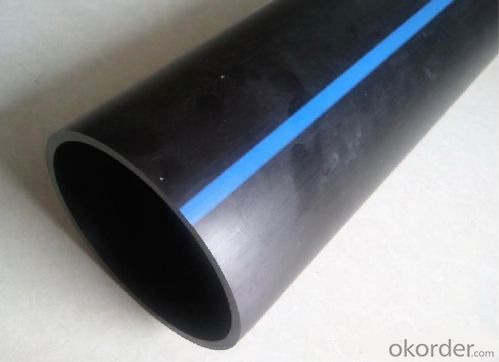

0.4MPa dn20-1600 HDPE80 Water supply Pipe

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

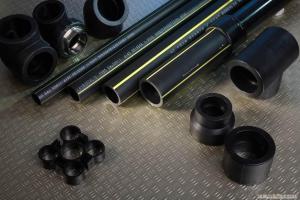

Product Name:High Density Polyethylene Pipe for water

Standard:GB/T13663-2000

Nominal Pressure:0.4 MPa

Nominal Diameter:140mm-1600mm

Wall Thickness:4.3mm-49.0mm

0.4MPa HDPE80 Water Pipe

High Density Polyethylene Pipe for water

Specification:

nominal diameter (mm) | tolerance (mm) | wall thickness (mm) | Tolerance (mm) | standard dimension ratio | Pressure (MPa) | Weight (kg/m) |

140 | 1.3 | 4.3 | 0.7 | SDR33 | 0.4 | 1.908 |

160 | 1.5 | 4.9 | 0.8 | SDR33 | 0.4 | 2.485 |

180 | 1.7 | 5.5 | 0.9 | SDR33 | 0.4 | 3.139 |

200 | 1.8 | 6.2 | 1.0 | SDR33 | 0.4 | 3.925 |

225 | 2.1 | 6.9 | 1.1 | SDR33 | 0.4 | 4.912 |

250 | 2.3 | 7.7 | 1.2 | SDR33 | 0.4 | 6.080 |

280 | 2.6 | 8.6 | 1.3 | SDR33 | 0.4 | 7.590 |

315 | 2.9 | 9.7 | 1.5 | SDR33 | 0.4 | 9.645 |

355 | 3.2 | 10.9 | 1.7 | SDR33 | 0.4 | 12.222 |

400 | 3.6 | 12.3 | 1.9 | SDR33 | 0.4 | 15.529 |

450 | 4.1 | 13.8 | 2.1 | SDR33 | 0.4 | 19.583 |

500 | 4.5 | 15.3 | 2.3 | SDR33 | 0.4 | 24.105 |

560 | 5.0 | 17.2 | 3.4 | SDR33 | 0.4 | 30.990 |

630 | 5.7 | 19.3 | 3.8 | SDR33 | 0.4 | 39.113 |

710 | 6.4 | 21.8 | 4.3 | SDR33 | 0.4 | 50.051 |

800 | 7.2 | 24.5 | 4.8 | SDR33 | 0.4 | 63.349 |

900 | 8.1 | 27.6 | 5.5 | SDR33 | 0.4 | 80.400 |

1000 | 9.0 | 30.6 | 6.1 | SDR33 | 0.4 | 99.054 |

1200 | 10.8 | 45.9 | 9 | SDR33 | 0.4 | 176.501 |

1400 | 12.6 | 53.5 | 10.6 | SDR33 | 0.4 | 241.482 |

1600 | 14.4 | 49.0 | 9.7 | SDR33 | 0.4 | 254.937 |

Features:

1.Environmental:in the process of pe pipe prodcution,not adding heavy metal salt stabilizer,non-toxic material,non-fouling layer,no bacteria,solving the secondary poluttion of urban drinking water.

2. corrosion resistance:expect a few strong oxidant,erosion resistant to a variety of checmical media;no electrochemical corrsion

3. Long serive life:under condition of rated temperature and pressure ,PE pipes can be used safely for more than 50 years

4. Impact resistance:good toughness,high impact strength, the heavy directly pressure through the pipe will not cause pipeline rupture.

5. Reliable connectivity:strength of PE pipe hot melt or fused joints is above the pipe ,seams do not load off due to soil movement or activity

6.Good construction performance: light pipe, simple welding process and convenient construction, lower engineering cost.

7.Great anti-tensile performance:Elongation break generally at more than 500%; Low temperature performance, used in temperature of below zero 20 to 40 degree .

8.Bigger flow capacity:inner wall roughness of PE pipe is not more than 0.01,which can effectively reduce water consumption.

- Q: Why can the air conditioning connection be made of copper tube? How about rubber tube and aluminium pipe? Please heroes pointing for the dishes.

- The pressure of the aluminum pipe is relatively small. "Again, when the aluminum pipe is too soft, it is easy to be flattened.".. Rubber tubes will decay if they are used! Withstand pressure is also high!

- Q: The engine cylinder head cover behind the drop rubber tube what reason (Xichai 490 engine) (note the valve chamber cover tube)

- The valve chamber of the engine cylinder head cover counterclockwise with 8~10 open wrench counterclockwise unscrew rocker screw. Place the piston at the top dead center, turn the rocker head wire clockwise until the hand can not be moved, then back half a circle, then lock the nut.

- Q: What is the principle of communicating devices? What if the rubber tube is used as a connecting device to change the water for the fish?

- Siphon principle: that is the principle of connected devices, plus in a closed container, the pressure on the liquid, everywhere equal. The siphon is filled with water, there is no gas, the water level of the water inlet is high, and the water outlet is closed with palm or other objects. The pressure is equal everywhere. When all are arranged, the water outlet is opened, although the atmospheric pressure on both sides is equal, the water level at the water inlet end is high and the pressure is large, and the water inflow is continuously flowed out of the water outlet.

- Q: The rubber is sheathed on a metal cylinder. How should they be connected?

- If you describe it, it is recommended that a soft binder such as 704 silicone gel will be used to prevent shock absorption and separation. Metal surface to rust treatment, clean can be coated adhesive, rubber cover surface is best polished, degreasing treatment effect is good!

- Q: The principle of the common bicycle valve

- An elastic thin edge hose is placed below to form the whole of the core. In fact, it is a one-way valve. When inflating the bicycle tyre, the compressed air in the air pump enters the valve core from the hollow part, and the elastic rubber tube is top, and the air enters the tyre.

- Q: What does rubber soft joint "KDTF" mean?

- KDFT flexible single ball rubber joints of rubber joints, rubber flexible connector is made of fabric reinforced rubber parts and flat joint, loose metal flange or threaded pipe flange, joint for pipe vibration noise reduction, displacement compensation.

- Q: Which is better for binding files with rubber tubes and cotton threads?

- In fact, the most suitable binding file is the file department I twine, such units are preserved, just to have you asked, hope to adopt

- Q: High pressure hose crimping connector, pressed on what position can effectively prevent the head off?

- High pressure hose crimping connector, pressed on what position can effectively prevent the head off, need professional technology, you can find professional installation.If the burst pressure is greater than the standard 4 times the work pressure, even the qualified hose.

- Q: How can the hose of natural gas be connected to the water heater?

- The gas source is connected with a gas water heater by using a flexible stainless steel bellows, and the ends of the pipe are pressed into bell mouths by special tools, and two movable nuts are pre sheathed. Connect one end of the pipe to the outlet of the gas meter (tighten the nut), and the other end is connected to the gas inlet of the heater (screw another nut) so that the connection between the gas pipe and the water heater is completed.

- Q: The selection of valves and fittings has the following requirements

- The joint of the valve is threaded with an internal thread, so that the connection in the installation is easier to select transition joints.

Send your message to us

0.4MPa dn20-1600 HDPE80 Water supply Pipe

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords