0.40 mm medium aluminum ultrathin electronic glass

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1141 m²

- Supply Capability:

- 114100 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

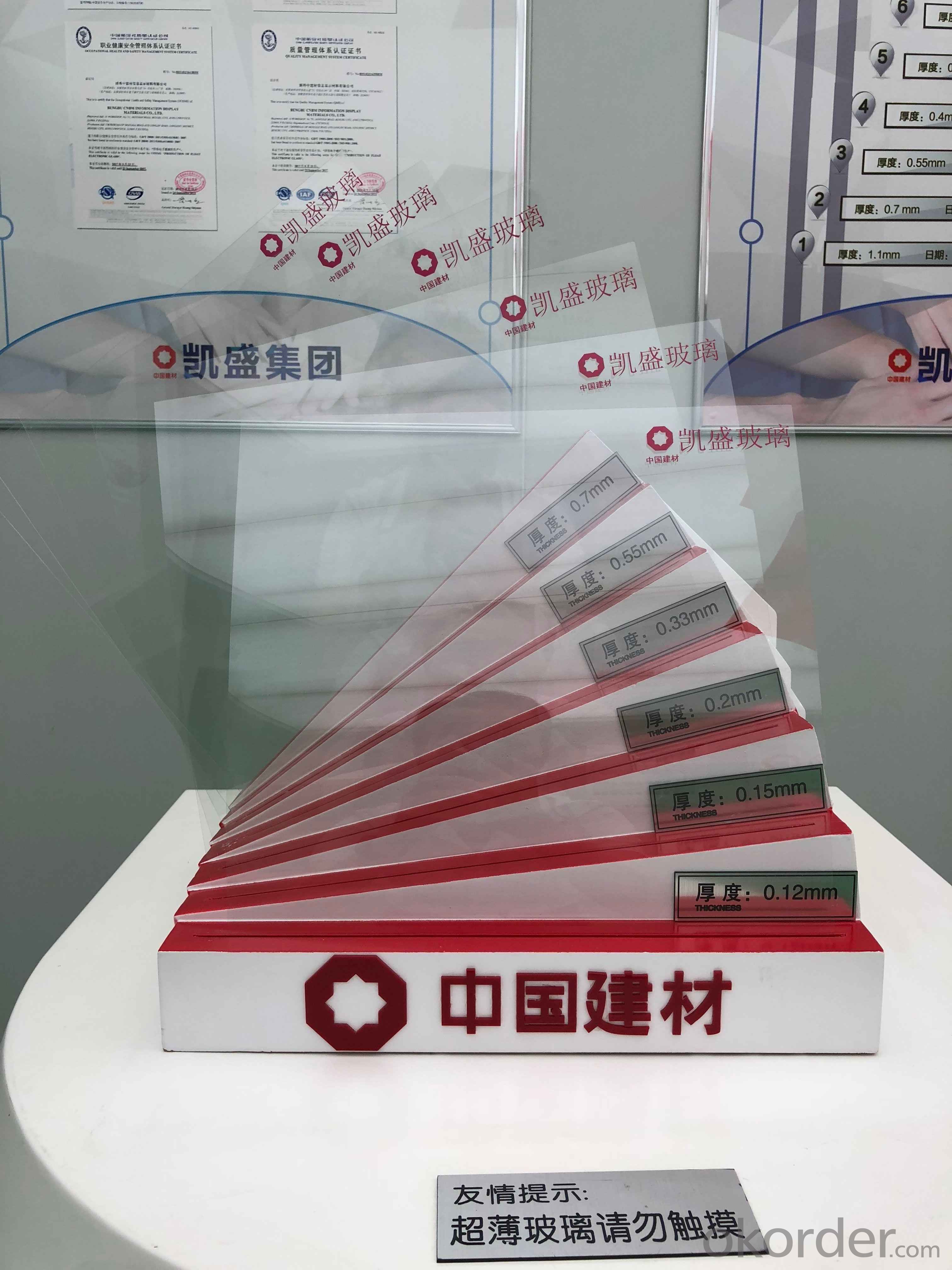

0.4 mm medium aluminum ultra-thin glass, electronic grade A, size 1244.6 * 1092.2 mm, 840 pieces per box.The thickness range is from 0.37 mm to 0.43 mm, and the thickness difference is ≤0.03 mm.

Electronic Glass is a kind of high strength touch and cover glass, which is one of the key materials of capacitive touch screen and also the protection cover glass. Widely used in smart phones, tablets, laptops, smart watches, car applications, public query systems, ATM machines, song and order system, industrial control, medical and other fields. In recent years, the demand for touch screen and cover glass is strong and growing steadily due to the increase in sales of electronic products such as smartphones and tablet computers, the increase in screen size and the development of the non-metal back cover market.

At the same time, due to its high strength, light weight and high transmission, high performance e-glass has been gradually accepted and applied in large-scale fields such as photovoltaics, new energy electric vehicles and high-speed trains, the future high-performance electronic glass products will have greater potential demand, the market prospects continue to look good.

- Q: What is the glass?

- Glass is quartz sand, soda ash, feldspar and limestone as the main raw material, by melting, forming, cooling and curing non-crystalline inorganic materials. It has the general material is difficult to have the transparency, has excellent mechanical and mechanical properties and thermal properties. Moreover, with the development of modern architecture needs, continue to multi-functional direction. Deep processing of glass products can control the light, adjust the temperature, to prevent dry sound and improve the decorative arts and other functions. Glass is no longer just a lighting material, but also a modern building a structural material and decorative materials.

- Q: Can architectural glass film be attached to a private car?

- Can not use their own paste can see you have no technology, posted bad there bubble.

- Q: I'm building an aquarium. The size of my tank is going to be 8 feet by 3 feet with 5feet height. What is the better material to build an aquarium with (Glass or Acrylic)?

- i would say glass because its a stronger material since its going to be a big tank hope that helps :-)

- Q: Automotive glass insulation film paste technology

- The most basic tools are roasted guns, watering cans, foil special agent (or detergent water), water scraper, paste scraper, deerskin, Huju, a knife, each model is not the same paste method is not the same , But there is a common point of glass must be cleaned, preferably in the clean film between the operation.

- Q: Frosted glass film can not be attached to the wall

- Frosted glass film can be attached to the wall, as long as the wall is smooth and can be affixed. Matte film is broadly divided into ordinary glass matte film and touch screen matte film, is the object from the surface smooth into the surface is not smooth.

- Q: I bought a tempered glass film online, but I will not paste, I will not paste around, how do?

- Tough is the best paste is thick piece

- Q: I'm putting glass Block windows in my barn. A lot of them. I need to build all the openings first. When figuring out my openings I need to allow for the gaps between the blocks and around the edge. What should that gap be?

- Glass masonry units are typically square, and are available in nominal 6, 8, and 12 in. sizes. Rectangular units are also available. Actual sizes are 1/4 in. less to allow for the typical 1/4 in. mortar joints. Unit thicknesses are either "standard" 3-7/8 in. or "thin" 3-1/8 in. or 3 in. for hollow units and for solid units respectively. Thin unit panels are typically used in residential and light commercial applications. For exterior applications you will want to add integral water repellents to the mortar to prevent water penetration. If you are talking about what size of an opening to use for your windows. That will depend on what the "rough opening" dimension is based on the window manufacturer. Typically is is 1 in. larger than the window size. This gives you 1/2 in. space all around the window for shims and alignment.

- Q: can i build a tank 2000x500x400mm with braces with 5mm thick glass?

- theoretically okorder /... visit these sites where you can find the safety factor with 5 mm but really 5mm is a nothing thickness as your width is 20 inch which is too much pressure on side glass

- Q: Building decoration commonly used varieties of light and heat glass

- Many types of glass, according to the chemical composition can be divided into soda-lime glass, aluminum-magnesium glass, potassium glass, borosilicate glass, lead glass and quartz glass.

Send your message to us

0.40 mm medium aluminum ultrathin electronic glass

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1141 m²

- Supply Capability:

- 114100 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Bengbu CNBM Information Display Materials Co.,Ltd

Bengbu CNBM Information Display Materials Co.,Ltd